Wind turbine blade with sections that are joined together

A technology of wind turbine blades and blades, which is applied in the field of segmented blades, can solve the problems of blade rigidity and weight considerations, and achieve the effects of increased strength, simple forming, and simple combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

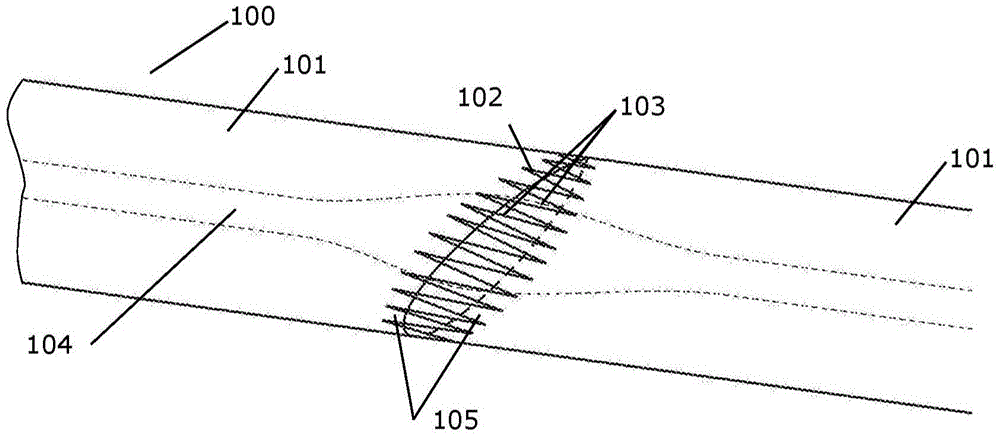

[0059] figure 1 A portion of a wind turbine blade 100 comprising two blade segments 101 joined at a blade joint 102 is shown. Each blade segment 101 includes at its connecting end 105 a plurality of prongs or fingers 103 interconnected across a joint 102 . The spar cap structure 104 of each blade segment is indicated by hatching. The spar cap structure may advantageously increase in size towards the blade joint 102 to increase the strength of the joint and the strength of the blade itself across the joint. In the illustrated embodiment, tooth-like protrusions are formed throughout the blade shell. In other embodiments, the serrations are formed in only a portion of each blade segment connection end, such as in a spar cap structure.

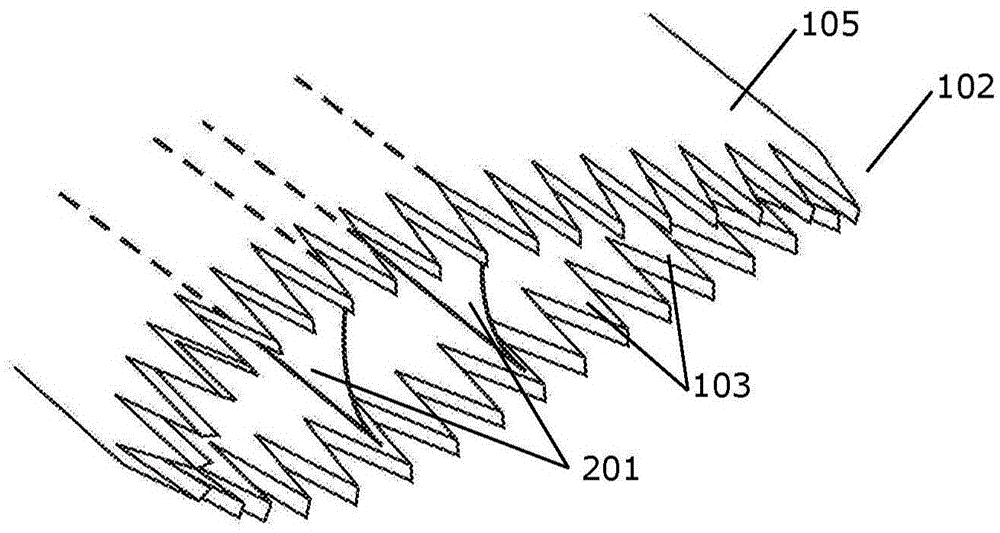

[0060] figure 2 The disassembled joint 102 is shown with serrations 103 formed in the blade segment connection ends 105 . Here, the serrations are formed in the shell structure comprised in the spar cap structure 104 of both the leeward and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com