Traditional Chinese medicine composition containing chrysanthemum and wild chrysanthemum volatile oil and preparation method of traditional Chinese medicine composition

A technology of wild chrysanthemum and composition, which is applied in the field of traditional Chinese medicine composition containing chrysanthemum and wild chrysanthemum volatile oil and its preparation, can solve the problems of low extraction rate, poor utilization effect, time-consuming inclusion rate, etc., and achieve high extraction rate , Improve bioavailability and prevent volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

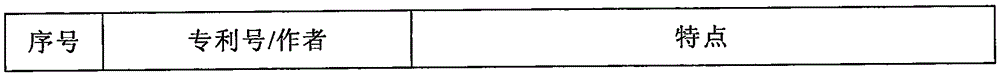

Problems solved by technology

Method used

Image

Examples

Embodiment 1

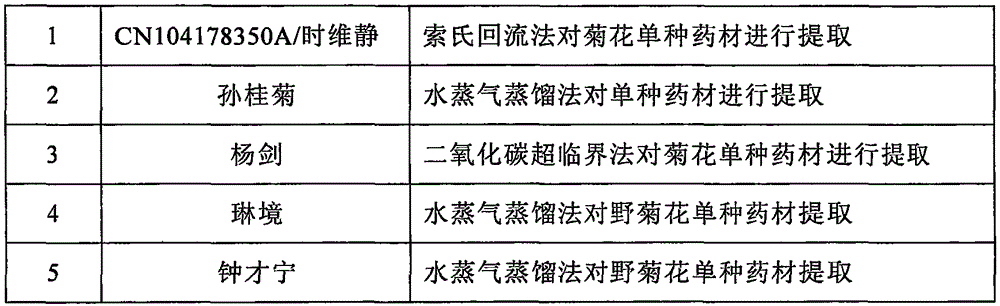

[0119] Weigh 150g of chrysanthemum and wild chrysanthemum respectively, pulverize, and pass through a 24-mesh sieve to obtain the coarse powder mixture of chrysanthemum and wild chrysanthemum. Put the coarse powder into a 1L extraction kettle, set the extraction pressure to 35MPa, extraction temperature to 35°C, separation kettle I pressure to 11MPa, temperature to 48°C; separation kettle II pressure to 8MPa, temperature to 36°C; carbon dioxide flow rate 11L / h, extract 60min after the instrument stabilizes, collect the extracts in the separation kettle I and the separation kettle II and merge and centrifuge the liquid, separate and remove the milky white lower layer liquid, get the supernatant to obtain the chrysanthemum wild chrysanthemum extract composition, the extraction composition yield is 4.26%. The ratio of the extract composition to β-cyclodextrin is 1:6, and the amount of water used is 4 times the weight of the extract composition, and inclusion is performed for 60 ...

Embodiment 2

[0121] Weigh 150g of chrysanthemum and wild chrysanthemum respectively, pulverize, and pass through a 24-mesh sieve to obtain the coarse powder mixture of chrysanthemum and wild chrysanthemum. Put the coarse powder into a 1L extraction kettle, set the extraction pressure to 30MPa, extraction temperature to 30°C, separation kettle I pressure to 10MPa, temperature to 45°C; separation kettle II pressure to 8MPa, temperature to 32°C; carbon dioxide flow rate 15L / h, extract for 120 minutes after the instrument stabilizes, collect the extracts in the separation kettle I and the separation kettle II and combine them with centrifugal separation, separate and remove the milky white lower layer liquid, take the supernatant to obtain the chrysanthemum wild chrysanthemum extract composition, and the yield of volatile oil is 4.02% . The ratio of the extract composition to β-cyclodextrin is 1:4, the amount of water used is 5 times the weight of the extract composition, and inclusion is car...

Embodiment 3

[0123] Weigh 150g of chrysanthemum and wild chrysanthemum respectively, pulverize, and pass through a 24-mesh sieve to obtain the coarse powder mixture of chrysanthemum and wild chrysanthemum. Put the coarse powder into a 1L extraction kettle, set the extraction pressure to 25MPa, extraction temperature to 30°C, separation kettle I pressure to 10MPa, temperature to 50°C; separation kettle II pressure to 7MPa, temperature to 35°C; carbon dioxide flow rate 13L / h, extract 90min after the instrument is stable, collect the extracts in the separation kettle I and the separation kettle II and merge and centrifuge the liquid, separate and remove the milky white lower layer liquid, take the supernatant to obtain the chrysanthemum wild chrysanthemum extract composition, and the yield of the volatile oil is 3.98 %. The ratio of the extract composition to β-cyclodextrin is 1:8, the amount of water used is 3 times the weight of the extract composition, and inclusion is carried out for 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com