Automatic loading and unloading processing center production line

A technology of automatic loading and unloading, processing center, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low degree of automation and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

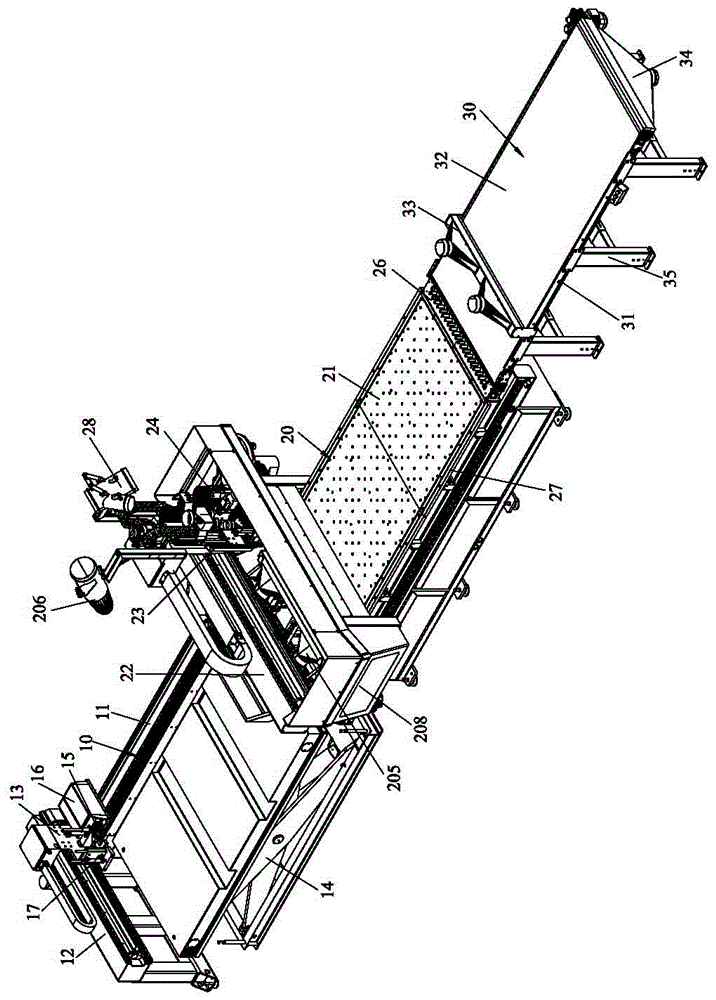

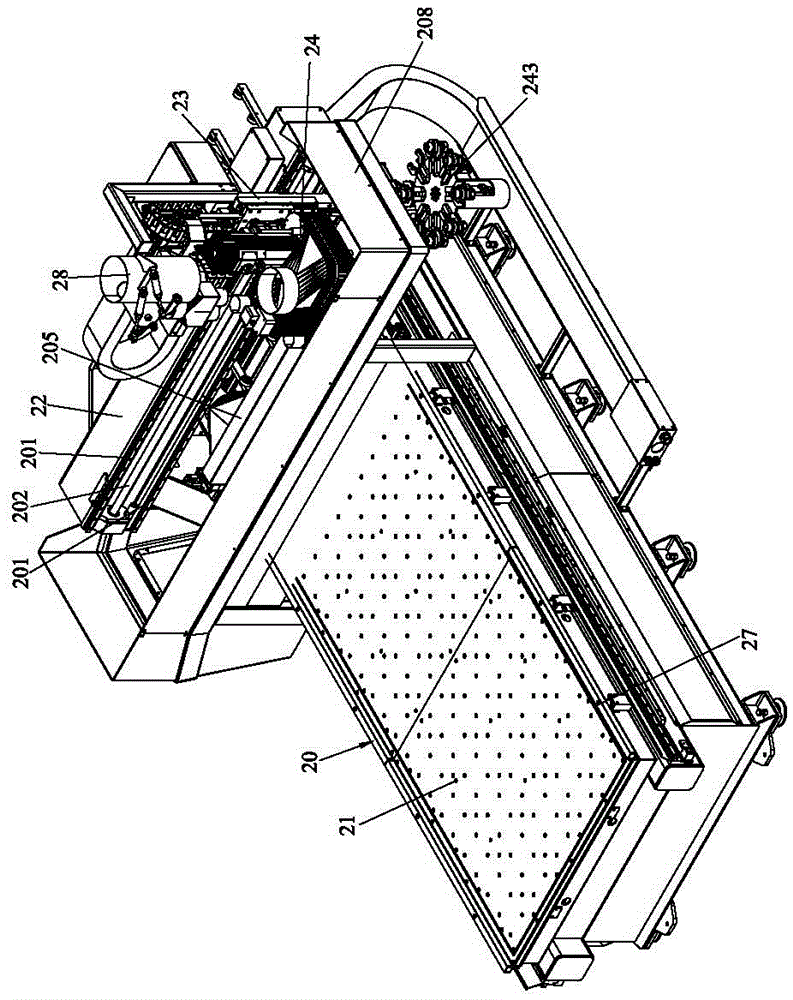

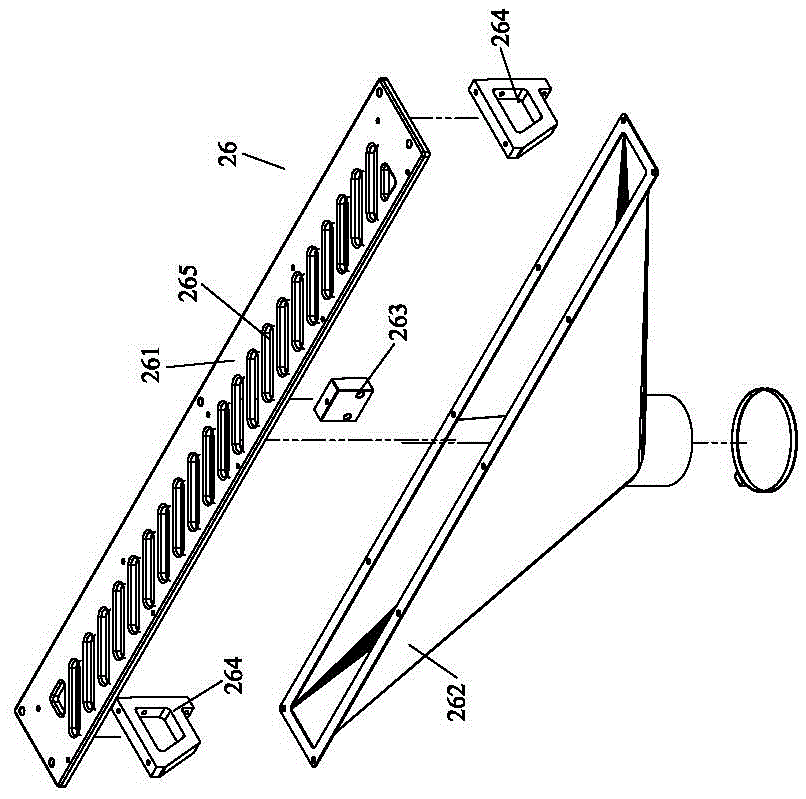

[0063] Please refer to Figure 1 to Figure 18 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a feeder 10, a processing center 20 and a blanking machine 30, and the feeder 10, the processing center 20 and the blanking machine 30 are sequentially transverse Set side by side.

[0064] The feeding machine 10 includes a feeding bed 11, a cantilever beam 12 and a sliding seat 13. The feeding bed 11 has a hydraulic lifting platform 14. The cantilever beam 12 can be arranged on the feeding bed 11 so as to move back and forth laterally. And located above the hydraulic lifting platform 14, the cantilever beam 12 extends longitudinally, the slide seat 13 can be vertically and movably arranged on the cantilever beam 12, and the slide seat 13 is provided with a labeling head 15 and a barcode printer 16; In the embodiment, the rear side of the cantilever beam 12 is provided with a rear-end floating pushing mechanism (not shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com