Multi-cylinder double-group circulation type hydraulic particle bar making machine

A circulating type, rod-making machine technology, applied in the direction of stamping machines, presses, material forming presses, etc., can solve the problems of large extrusion force and high combustion calorific value, and achieve large extrusion force and high combustion calorific value , The effect of solving environmental protection utilization and environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

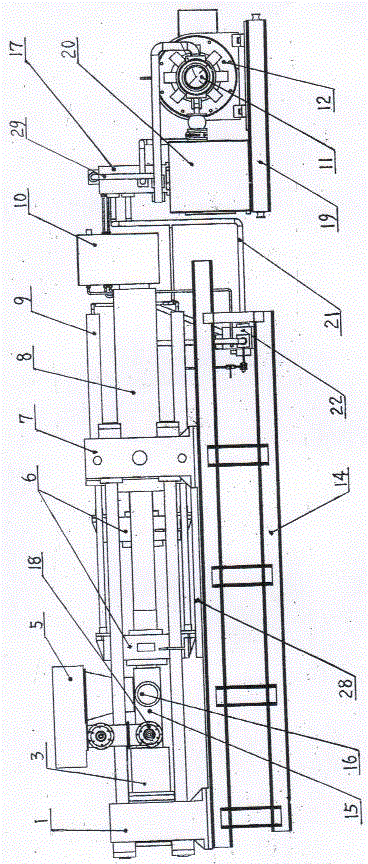

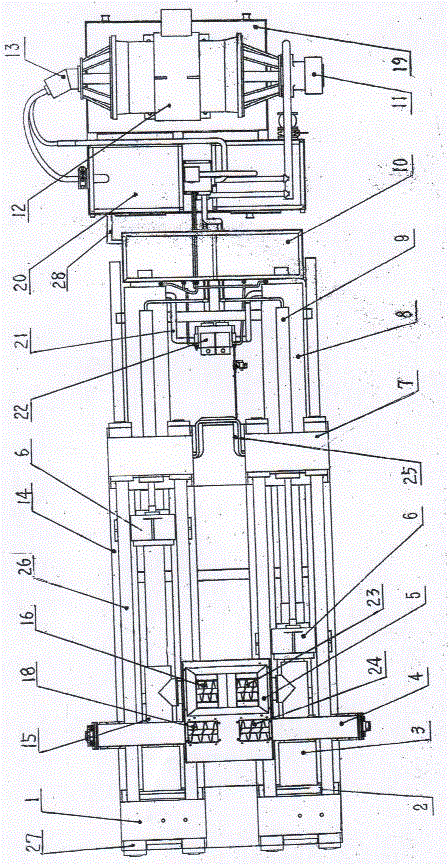

[0010] Examples, see attached figure 1 , 2 , the motor seat 19 of the multi-cylinder double-group circulating hydraulic pellet making machine is fixedly equipped with an oil tank 20 in the front and a main motor 12 in the rear. The right end of the main motor 12 is connected to the high-pressure pump 13, and the left end of the main motor 12 is connected to the low-pressure pump. 11. The high-pressure pump 13 is respectively connected to the oil tank 20 and the valve group 22 through the pipeline 21, and the valve group 22 is respectively connected to the control block 17, the main oil cylinder 28, the auxiliary oil cylinder 29 and the oil tank 20 through the pipeline 21, and the low-pressure pump 11 is respectively connected to the oil tank through the pipeline 21 20, valve group 22 and four auxiliary oil cylinders 9. The top of the oil tank 20 is equipped with a control block 17, and the control block 17 connects two main oil cylinders 8, four auxiliary oil cylinders 9, va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com