Wear-free hydraulic braking method, device and vehicle

A hydraulic braking, wear-free technology, applied in the direction of brake transmission, brakes, vehicle parts, etc., can solve the problems of increasing consumer extra expenses, easy to reduce the braking effect due to heat, easy to generate friction dust, etc. Simple and reliable, compact structure, the effect of increasing the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

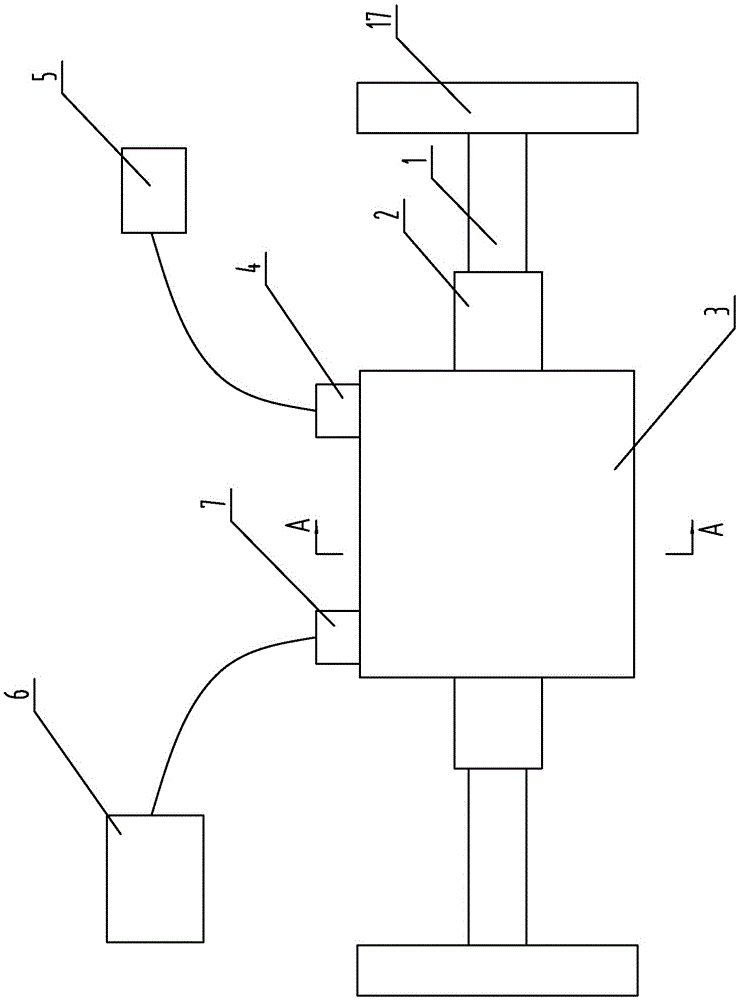

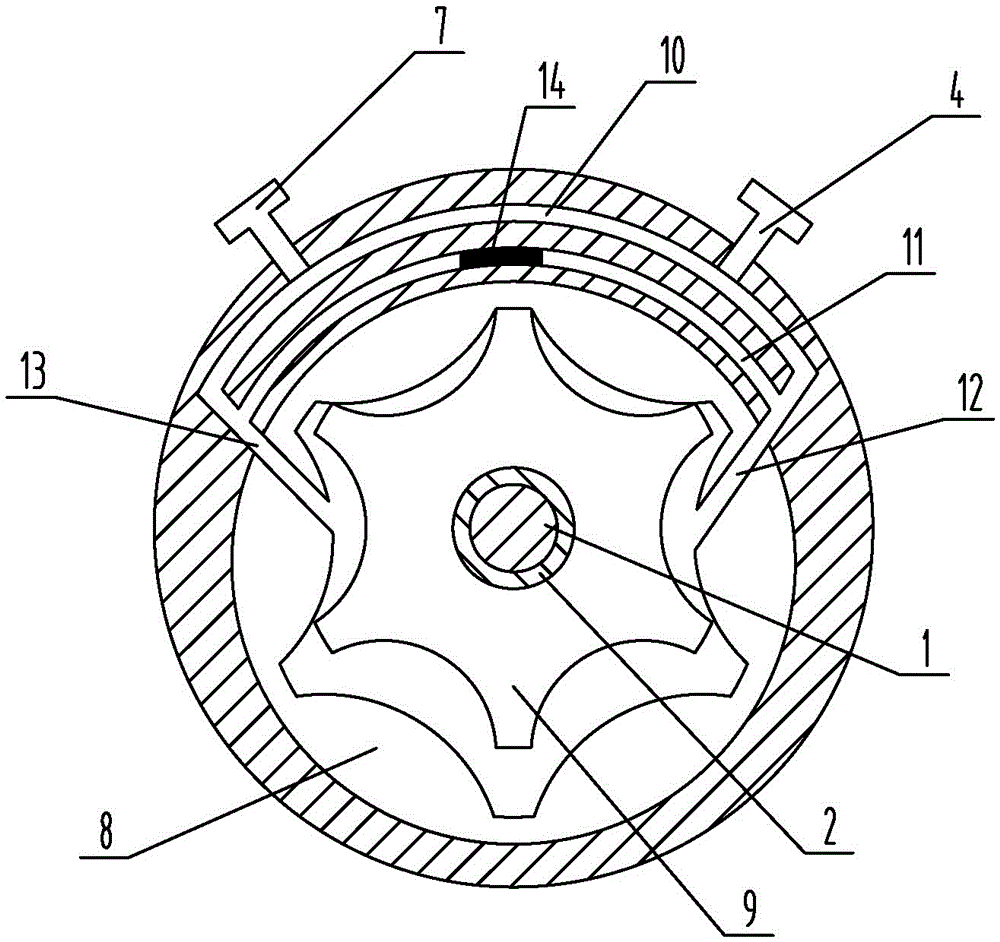

[0031] like figure 1 and figure 2 As shown, the present embodiment adopts the gear pump 3 of the internal meshing mode, and the pump housing of the gear pump 3 is provided with an inner ring gear 8, and the inner ring gear 8 is equipped with a gear 9, and the gear 9 is meshed with the inner ring gear 8, and the gear 9 rotates to drive the inner ring gear 8 to rotate, and the rotating shaft of the gear 9 is used as the pump shaft 2 of the gear pump 3 . A cavity is provided on the pump shaft 2 of the gear pump 3, the wheel shaft 1 of the vehicle is penetrated in the cavity, and the fixed connection between the wheel shaft 1 and the pump shaft 2 is realized through components such as keys or pins. Open the first channel 10 in the pump body of the gear pump 3, the first channel 10 communicates with the liquid inlet 13 and the liquid outlet 12 of the gear pump 3, the brake valve 4 is installed on the first channel 10, and the brake valve 4 is connected to the vehicle. The brake ...

Embodiment 2

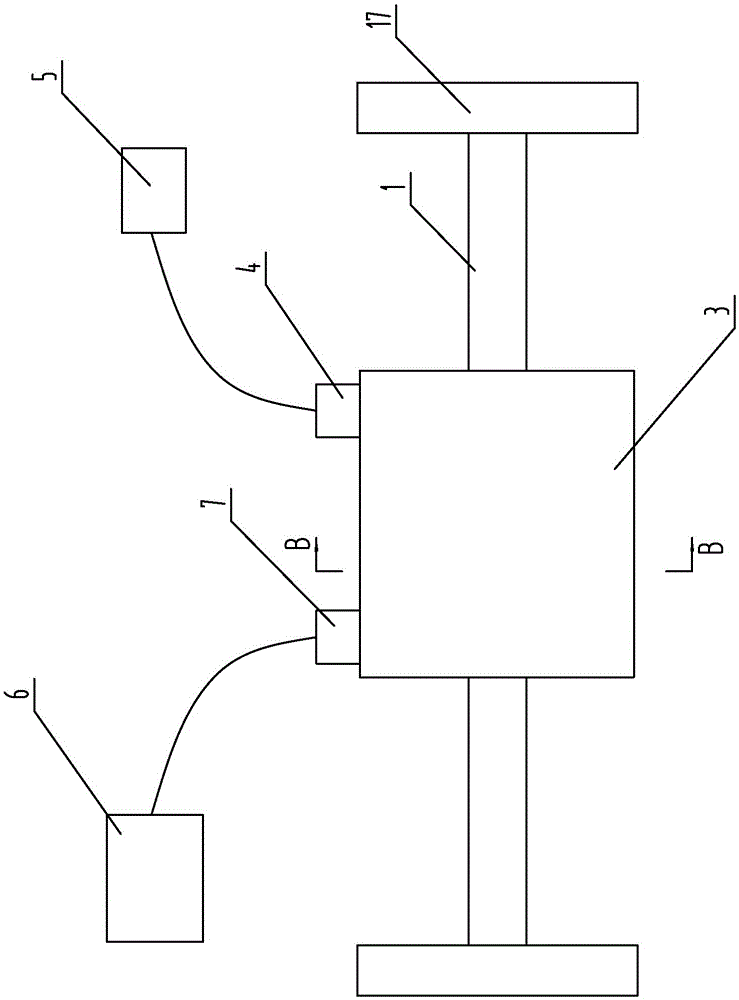

[0037] The difference between this implementation and the first embodiment is that: image 3 and Figure 4 As shown, the gear pump 3 of this embodiment adopts an external meshing mode, that is, a driving wheel 15 and a driven wheel 16 are arranged in the pump casing, the rotating shaft of the driving wheel 15 is used as the pump shaft 2, and the driven wheel 16 is only used to cooperate with the driving wheel 15 to complete the liquid. transmission, no connection with other devices.

[0038] In addition, the pump shaft 2 has two protruding sections protruding from the pump casing, the total length is compatible with the wheel shaft 1, and the hub 17 is assembled on the pump shaft 2, that is, the pump shaft 2 is used as the wheel shaft 1 to realize the combination of the pump shaft 2 and the wheel shaft 1. Two for one. This method is suitable for vehicles that have not left the factory, that is, the gear pump 3 with the appropriate length of the pump shaft 2 is directly selec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com