Contact line operation tower wagon for electrified overhead contact lines of subway

A catenary and ladder car technology, applied in the direction of overhead lines, railway car body parts, ladders, etc., can solve the problems of non-adjustable working height of ladder cars, easy tipping of ladder cars, loud wheel noise, etc., to achieve light weight, high Construction efficiency and the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

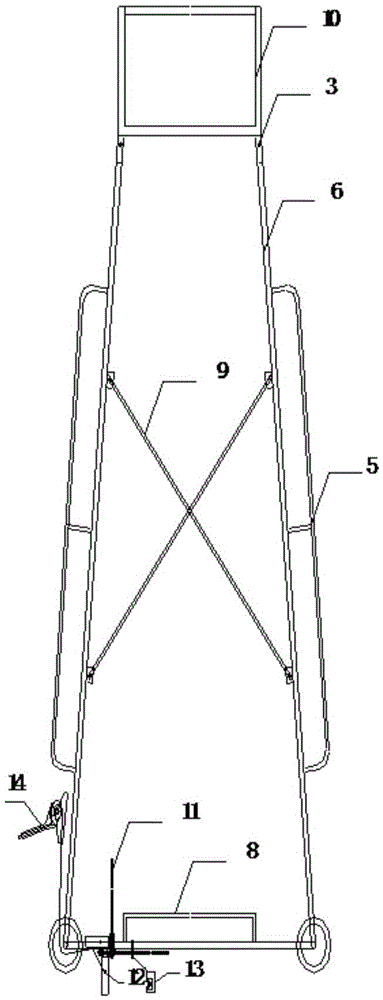

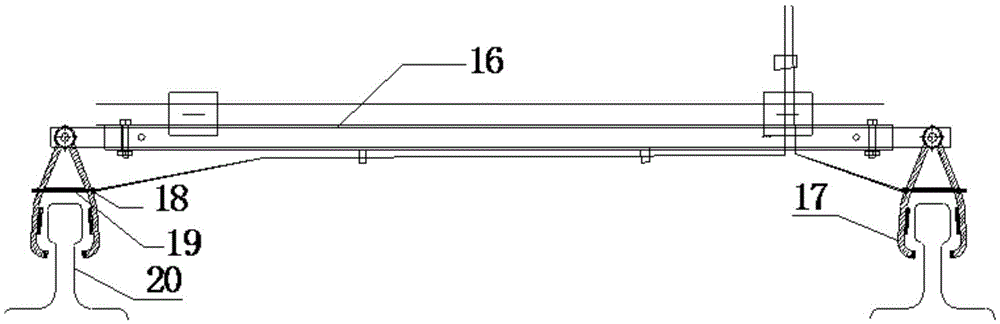

[0027] A catenary operation ladder car used for the electrified overhead catenary of subways, including a ladder car chassis, on which the ladder car body is fixed; Both ends are respectively equipped with hoops 17, and the cross bar 16 is provided with a handle positioning hole 12, and a handle 11 is inserted in the handle positioning hole 12; There are through holes respectively on the top, and screw rods are inserted between the through holes. The heads of the screw rods are all blocked on the outside of the corresponding pins, and the tail ends of the screw rods are stretched out of the through holes and are fixed with a backguy 15. A return spring is set between the left and right pinches; the outside of the ladder car body is equipped with a brake pull rod 14 that can control the length of the cable.

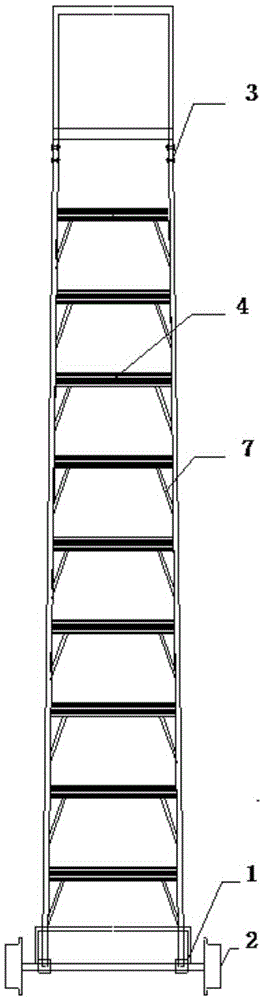

[0028] figure 1 The main beam 6 of the middle ladder car is connected to the nylon insulated wheel 2 through the ladder shoe assembly 1, the ladder rod 4, the diagonal st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com