brake minecart

A mining car and brake beam technology, applied in the field of brakeable mining cars, can solve the problems of secondary injury accidents, heavy maintenance workload, self-collision and other problems, and achieve high braking reliability, fast and reliable braking, The effect of large braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

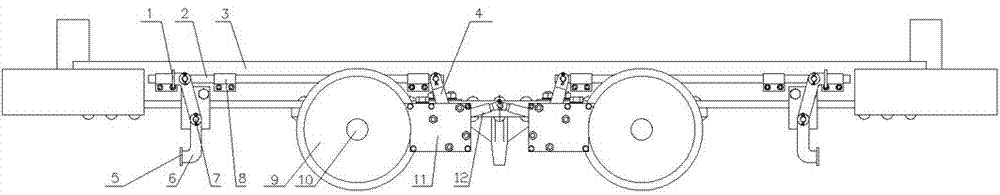

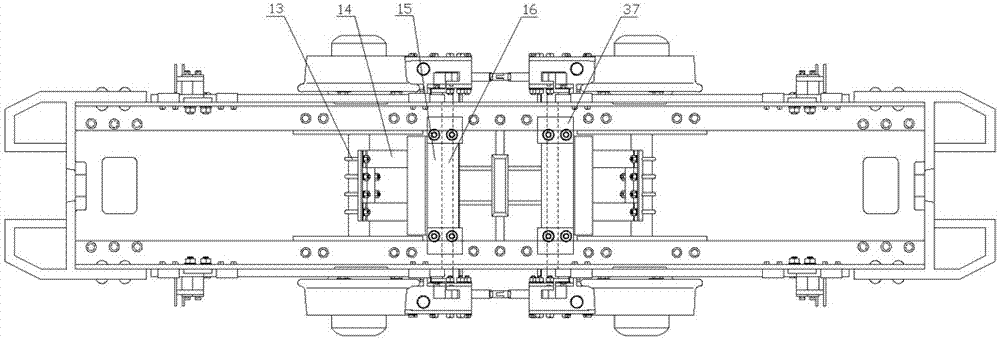

[0051] A brakeable mine car used for parking and parking in flat roads and small slope inclined roads:

[0052] see figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 , Figure 8 , Figure 15 , Figure 16 , Figure 17 , Figure 18 , four brake assemblies 11 corresponding to four wheels 32 respectively, two drive shafts 16 in the same direction as the mine wheel pair shaft 10 are provided on the mine car chassis 3 between the two mine wheel pairs 9; 16 is provided with a brake beam 15 in the same direction, the brake beam is suspended on the beam of the mine car chassis 3 through the pressure plate 37, and the two ends of the brake beam 15 are respectively positioned with the brake assemblies 11 on both sides through the positioning plate 31 Connection, the brake beam 15 is connected with the brake beam bracket 14, the adjustment pad 35 is arranged between the brake beam 15 and the brake beam bracket 14, the brake beam bracket 14 is aligned with the mine wheel thr...

Embodiment 2

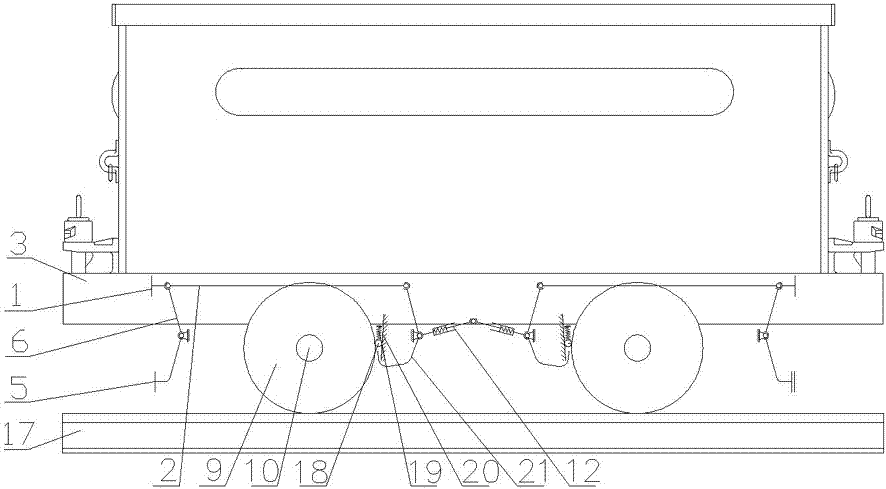

[0058] A brakeable mine car used for anti-sports car in a steep inclined roadway:

[0059] see Figure 4 , Figure 5 , the difference from Embodiment 1 is that the conjugate shaft 34 between the conjugate arms 12 of the two brake assemblies 11 on the same side of the transmission shaft 16 is removed, and the roller 25 is installed on the conjugate arm 12, and the two The isolation baffle plate 23 that cooperates with the roller is installed on the mine car underframe 3 between the rollers 25.

[0060] How it works: see Figure 4 , Figure 5 , by installing an isolation baffle 23 between the two rollers 25 on the front and rear two conjugate arms 12, the front and rear brake assemblies 11 are disconnected from each other, and the upper brake pedal 5 is stepped on in advance before going up, so that the upper mine wheel of the mine car 9 is placed in the braking state, and the lower mine wheels are placed in the brake release state (otherwise the mine car cannot go up). is ...

Embodiment 3

[0062] A brakeable mine car used for anti-sports car downhill in a steep inclined roadway:

[0063] see Figure 4 , Figure 5 , the difference from Embodiment 2 is that a synchronous clamp 24 compatible with the unlocking arm 21 is installed on the conjugate arm 12, so that the rotation angle of the brake arm 6 is consistent with the rotation angle of the unlocking arm 21, and the brake arm above the slope 6, a pre-braking hanging plate 22 is installed, and the other end of the pre-braking hanging plate 22 is connected with the traction wire rope.

[0064] How it works: see Figure 4 , Figure 5 , when lowering an empty car, because of the small weight, the probability of breaking the rope is not high, and it can be carried out in the state of releasing the brake, but when the mine car is transporting heavy objects in an inclined road, it is dangerous to release the brake directly, so set the synchronization card The hoop 24 and the pre-brake hanging plate 22, the synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com