Automated guided railless carrying train with flexibly configured kinds of carrying trains and operation control method

A trackless vehicle and automatic guidance technology, which is applied in the fields of automatic guide train and control, automatic guide trackless vehicle and operation control, can solve the serpentine swing, increase the danger of driving out of the guide path, and run the Trajectory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be described in further detail below in conjunction with the accompanying drawings.

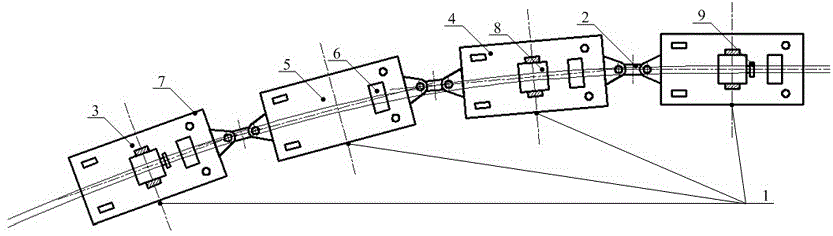

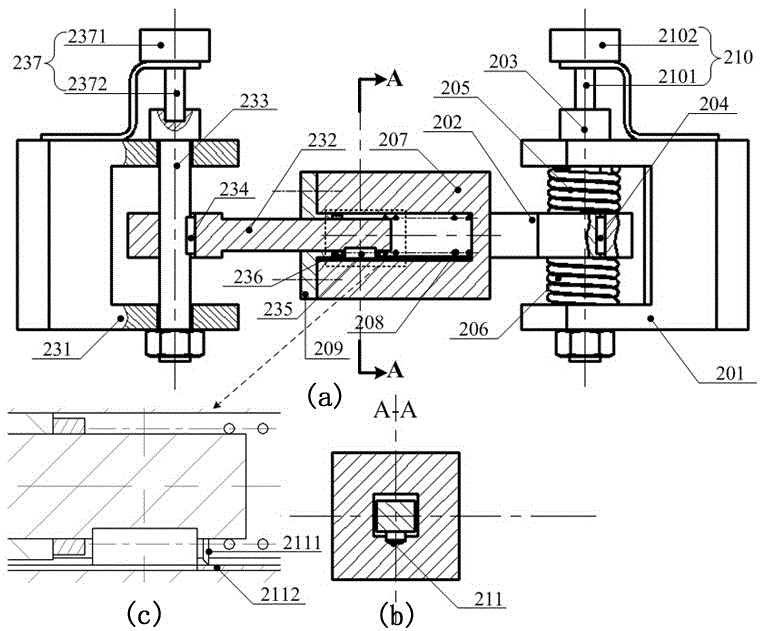

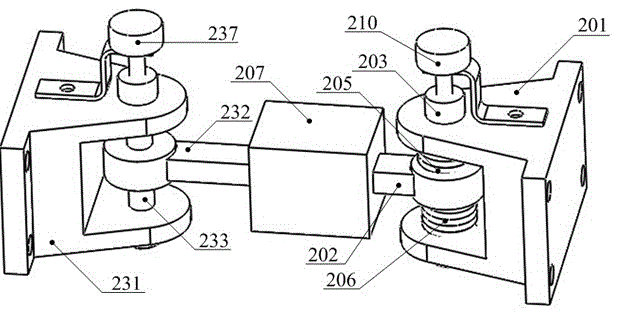

[0061] Such as figure 1 As shown, the automatically guided and configurable trackless carrier train of the present invention includes a plurality of carrier vehicles 1, each of which is connected by a push-pull device 2 with three-dimensional independent degrees of freedom. The vehicle 1 is divided into an automatic guided power vehicle 3 , a power vehicle 4 and a follow-up vehicle 5 . The automatic guided power vehicle 3 includes a vehicle frame 7 and an on-board controller 6 installed on the vehicle frame, a driving wheel device 8, a guidance sensor 9, an electronic compass and a power supply device. The vehicle-mounted controller 6 is electrically connected with the driving wheel device 8, the guiding sensor 9, and the electronic compass, and the power supply device is used to supply power to the driving wheel device 8, the guiding sensor 9, and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com