Sterilization logistics system and sterilization logistics method

A logistics system and logistics technology, applied in packaging sterilization, conveyors, mechanical conveyors, etc., can solve the problems of inconvenient operation, large space occupied by sterilization logistics lines, etc., and achieve convenient operation, small occupied space, and structural design. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

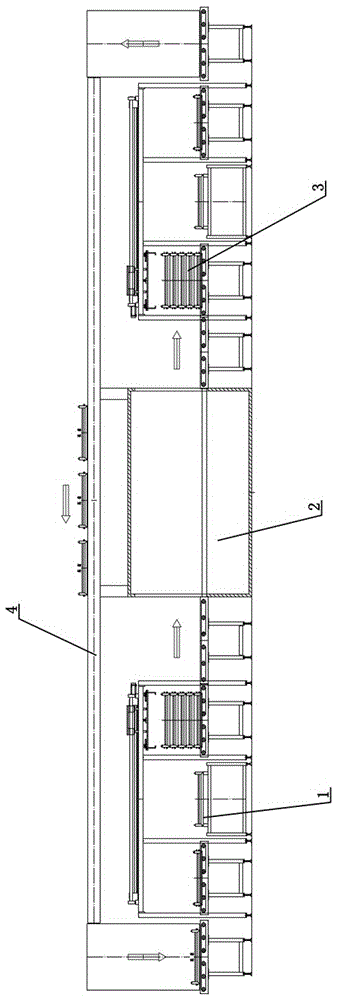

[0037] Such as Figure 1 to Figure 3 As shown, the first embodiment of the sterilization logistics system of the present invention, the logistics system includes a loading station 1, a sterilization station 2 and an unloading station 3 connected in sequence, and also includes a vertical conveying roller table 4 , one end of the vertical conveying roller table 4 is connected with the loading station 1, and the other end is connected with the unloading station 3, the loading station 1, the sterilization station 2, the unloading station 3 and the vertical conveying roller table 4 Enclosed to form a vertical closed-loop conveying line for circulating the disc body in the vertical plane. In this structure, the bottle body enters the sterilizing station 2 from the loading station 1 for sterilization, and then enters the unloading station 3 to discharge the bottle, and the empty bottle will enter the loading station through the vertical conveying roller table 4 1. A set of vertical ...

Embodiment 2

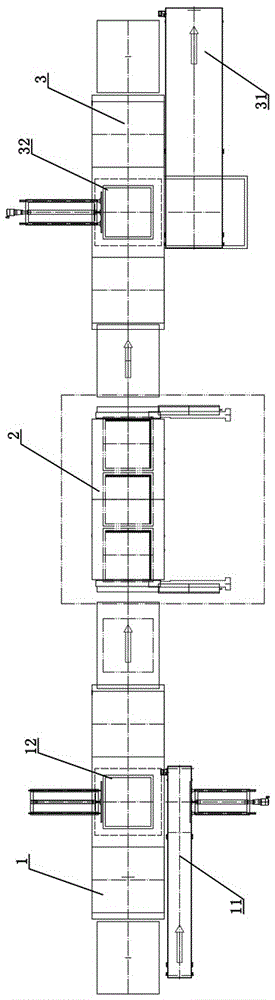

[0043] Such as Figure 4 and Figure 5 As shown, the second embodiment of the sterilization logistics system of the present invention, the logistics system is basically the same as that of Embodiment 1, the only difference is that the vertical conveying roller table 4 is arranged at the loading station 1, the sterilization station 2 and Below the unloading station 3. In this structure, through the combination of the grabbing mechanism 5 and the vertical conveying roller table 4 below, it is no longer necessary to set up and down roller tables, and its structure is simpler and more compact, saving space, saving power, personnel maintenance, and dismantling. Easy to install.

Embodiment 3

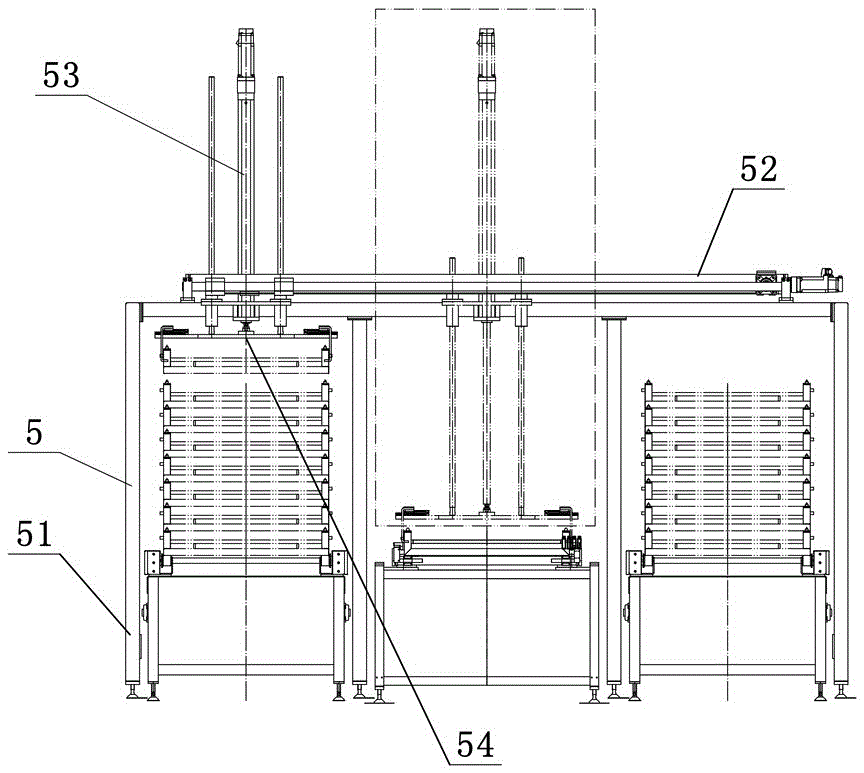

[0045] Such as Image 6 and Figure 7 As shown, the third embodiment of the sterilization logistics system of the present invention, the logistics system is basically the same as that of Embodiment 1, the difference is only that: the tray loading station 1 includes a bottle feeding area 11, a tray loading area 12 and a tray loading area connected in sequence. Circulation area 13, the tray loading circulation area 13 is connected with the tray inlet end of the sterilization station 2, and the tray unloading station 3 includes a bottle output area 31, an unloading tray area 32 and an empty tray circulation section 33 connected in sequence, and the empty tray circulation section 33 links to each other with the dish-out end of sterilization station 2. In this structure, the loading and unloading panel area and the sterilization station 2 are not on the same line, and the purpose of hoarding bottling trays can be realized through the tray loading circulation area 13, and the purpo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com