A method and equipment for simultaneous decolorization and nitrogen recovery of high-concentration printing waste liquid

A recovery equipment and high-concentration technology, which is applied in the field of textile printing and dyeing industry, can solve the problems of secondary pollution, cannot remove ammonia nitrogen at the same time, increase the content of acid radical ions, etc., and achieve the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

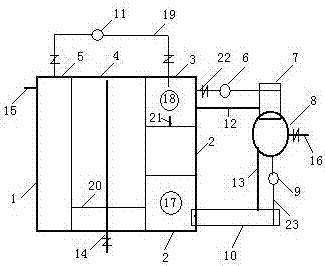

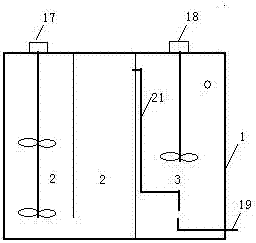

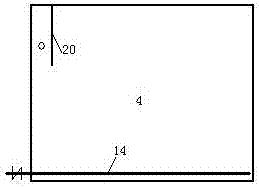

[0037] refer to figure 1 , figure 2 and image 3 .

[0038] The invention provides a high-concentration printing waste liquid synchronous decolorization and nitrogen recovery treatment equipment, which includes a processor 1, a #1 filter 7, a nitrogen recovery tank 8 and a #2 filter 10.

[0039] The processor 1 described therein comprises a reaction tank 2 , a primary separation tank 3 , a secondary separation tank 4 , a water storage tank 5 , and a return water pump 11 .

[0040] The reaction tank 2 is divided into two compartments, the bottom of which is connected to each other. A mixer 17 is arranged in the first compartment reaction tank, and the stirred waste liquid reacts with the resin to form a paste. The upper part of the second compartment of the reaction tank is provided with a catheter 21 and a first-stage The separation tank 3 is connected, and the diameter of the catheter is greater than 20cm;

[0041] The first-stage separation tank is provided with a mixer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com