Wet airflow crushing dispersion method of nanometer calcium carbonate

A technology of nano-scale calcium carbonate and airflow milling, which is applied in chemical instruments and methods, dyeing polymer organic compound treatment, inorganic pigment treatment, etc. It can solve the problems that particles are easy to agglomerate, cannot meet the application requirements, and the dispersion effect is not ideal. , to achieve the effect of fineness and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

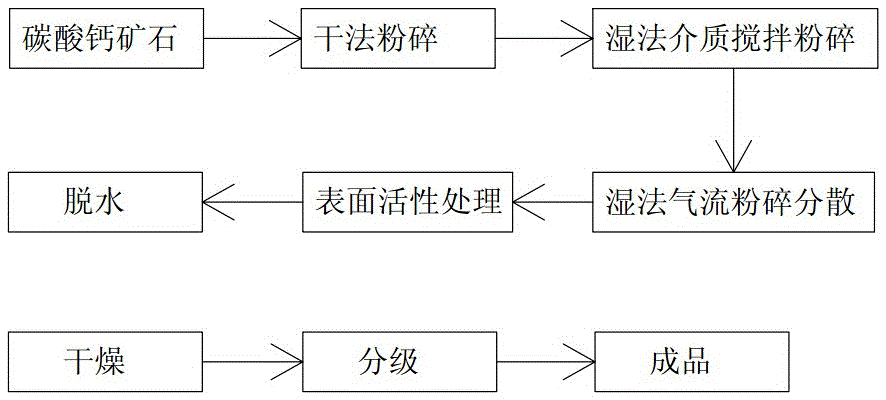

[0021] The wet jet pulverization dispersion method of a kind of nanoscale calcium carbonate described in present embodiment 1, such as figure 1 shown, including the following steps:

[0022] (1) Dry crush the calcium carbonate ore to a powder with a fineness of 400 meshes, then mix the powder with water to make a slurry, and the proportion of the powder to the slurry is 70-75%;

[0023] (2) Add a dispersant to adjust the viscosity of the slurry;

[0024] (3) The slurry is ground by a wet medium agitating pulverizer to a particle size of less than 2 microns;

[0025] (4) Add at least one dispersant to the slurry, and enter the crushing chamber of the wet jet milling disperser. There are stators and rotors nested in each other in the crushing chamber, and the rotor drives the slurry in the crushing chamber to rotate at high speed to generate great centrifugal force and A vacuum state is formed, so that the multi-phase materials with larger particles are sucked into the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com