A device used in catalytic cracking regenerator for pre-stripping and rapid removal of oil and gas on catalyst surface

A catalytic cracking and catalyst technology, applied in catalytic cracking, cracking, chemical instruments and methods, etc., can solve the problems of increasing the yield of dry gas and coke, shortening the residence time of oil and gas, reducing the yield of light oil, etc. The effect of lifting, reducing the average residence time and reducing the output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and example the present invention will be further described:

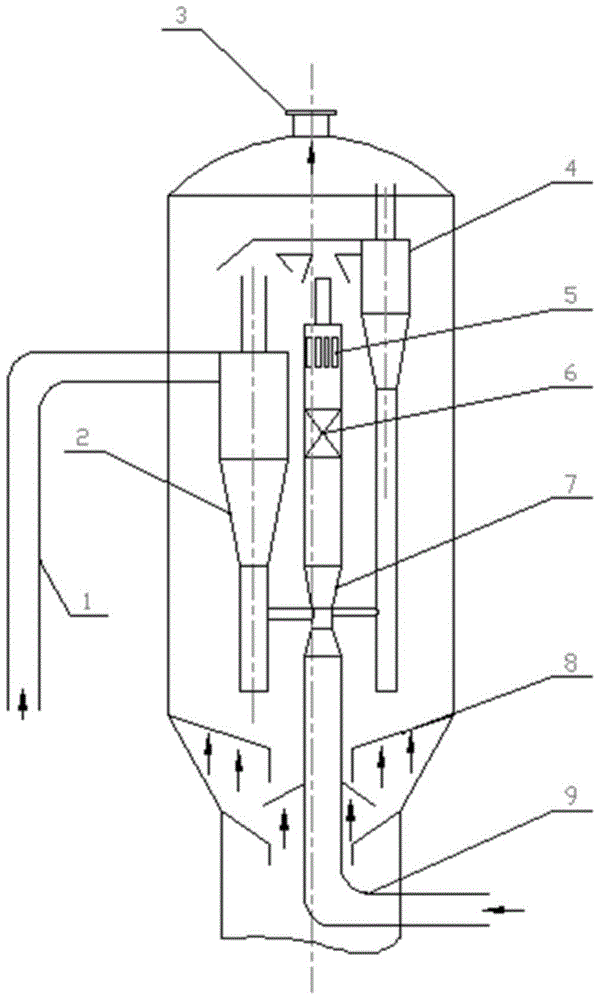

[0014] The mixture of catalyst and oil and gas produced in the catalytic cracking regenerator enters the coarse cyclone (2) separator of the settler from the outlet of the riser (1), so that the oil, gas and catalyst are quickly separated, and the separated catalyst is unloaded along the coarse cyclone leg , the oil and gas enter the top-spin (4) separator of the settler through the coarse-spin exhaust core pipe for further secondary separation, and the oil and gas from the exhaust core pipe of the top-swirl (4) finally pass through the oil-gas outlet of the settler (3) Enter the follow-up fractionation system, the lower part of the material legs of the coarse rotation (2) and the top rotation (4) are respectively connected to a branch pipe, and the other end of the branch pipe is connected to the throat of the Venturi tube (7), when the stripping steam When pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com