Anti-bleeding digital printing method

A digital printing and anti-seepage technology, which is applied in dyeing, textile and papermaking, fiber treatment, etc., can solve the general effect of anti-seepage and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

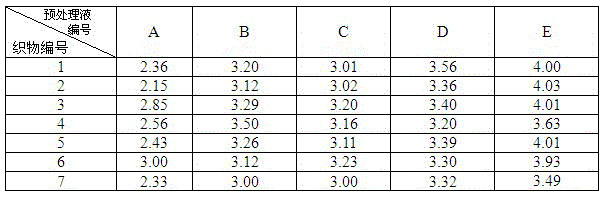

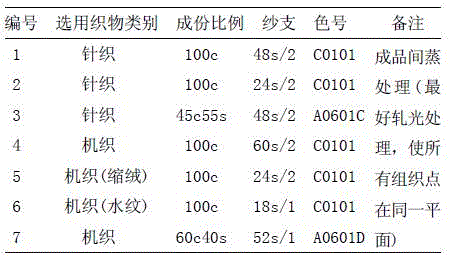

[0012] An anti-seepage digital printing method, comprising the following steps: fabric pretreatment, drying, spraying a physical adsorbent on the fabric, drying, spraying a physical adsorbent on the entire fabric, drying before printing, inkjet printing, and drying after printing , steamed, washed and dried. The physical adsorbent is calcium carbonate powder liquid or mesoporous silicon dioxide or mesoporous titanium dioxide. In the process of locally spraying physical adsorbent on the fabric, the injection position of the physical adsorbent is the inkjet position of the pattern required by the final product, and the printing nozzle involved in the spraying physical adsorbent and the inkjet printing process is the same nozzle, The physical adsorbent tube and the ink tube are respectively connected in the aforementioned two different processes. In the process of fabric pretreatment, the weight fraction of each component of the pretreatment liquid is: 2% paste A-9, 2% SW-MN-08,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com