Wind generating set, main bearing cooling system thereof and cooling control method

A technology for wind turbines and cooling systems, applied in bearing cooling, wind turbines, engines, etc., can solve the problems of poor cooling effect of the main bearing, and achieve the effect of good cooling effect and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The wind turbine generator set, the main bearing cooling system and the cooling control method thereof according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

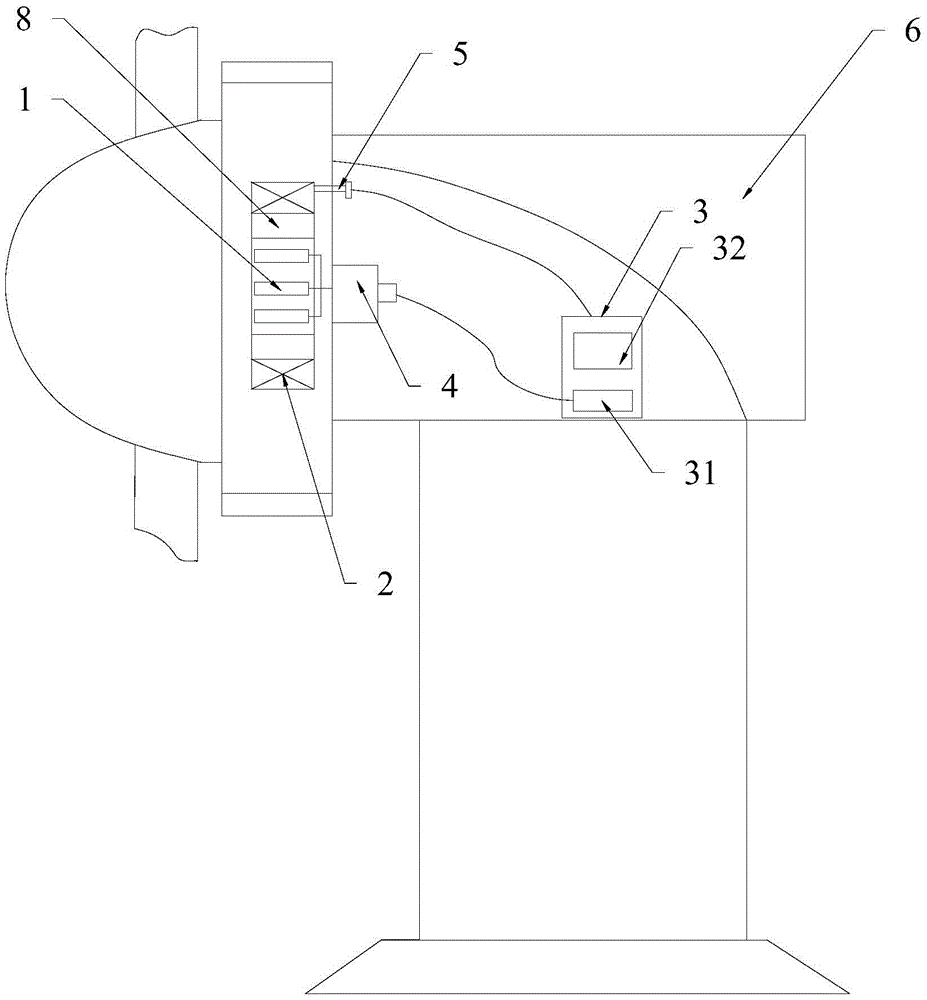

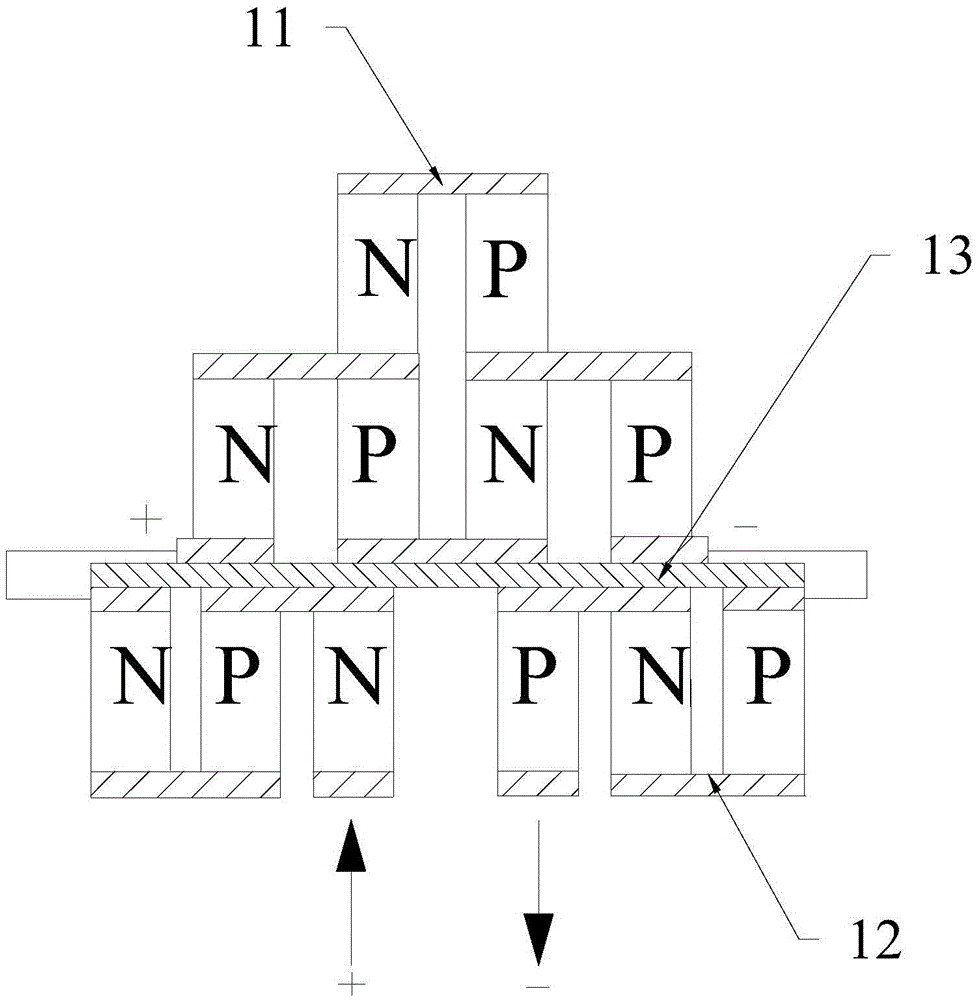

[0027] like figure 1 As shown, the wind power generating set includes a nacelle 6, a fixed shaft connected to the nacelle 6, a main bearing 2 arranged in the fixed shaft, a moving shaft 8 passing through the main bearing 2, and the like. Among them, the outer ring of the main bearing 2 is installed in the fixed shaft hole, and remains stationary together with the fixed shaft, and the inner ring of the main bearing 2 is installed on the moving shaft 8, and the follower shaft 8 rotates together. The moving shaft 8 is connected with the rotor support and the impeller system, and rotates with the impeller system. During the working process of the wind turbine, the main bearing 2 will generate heat, so that the operating temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com