A ball valve for conveying coal-water slurry

A coal-water slurry and ball valve technology, which is applied in the direction of sliding valves, valve devices, and cocks including cut-off devices, can solve problems such as ball valve body wear or blockage, coal-water slurry leakage, ball valve impact wear, etc., to prolong the service life , reduce the effect of harm and reduce wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

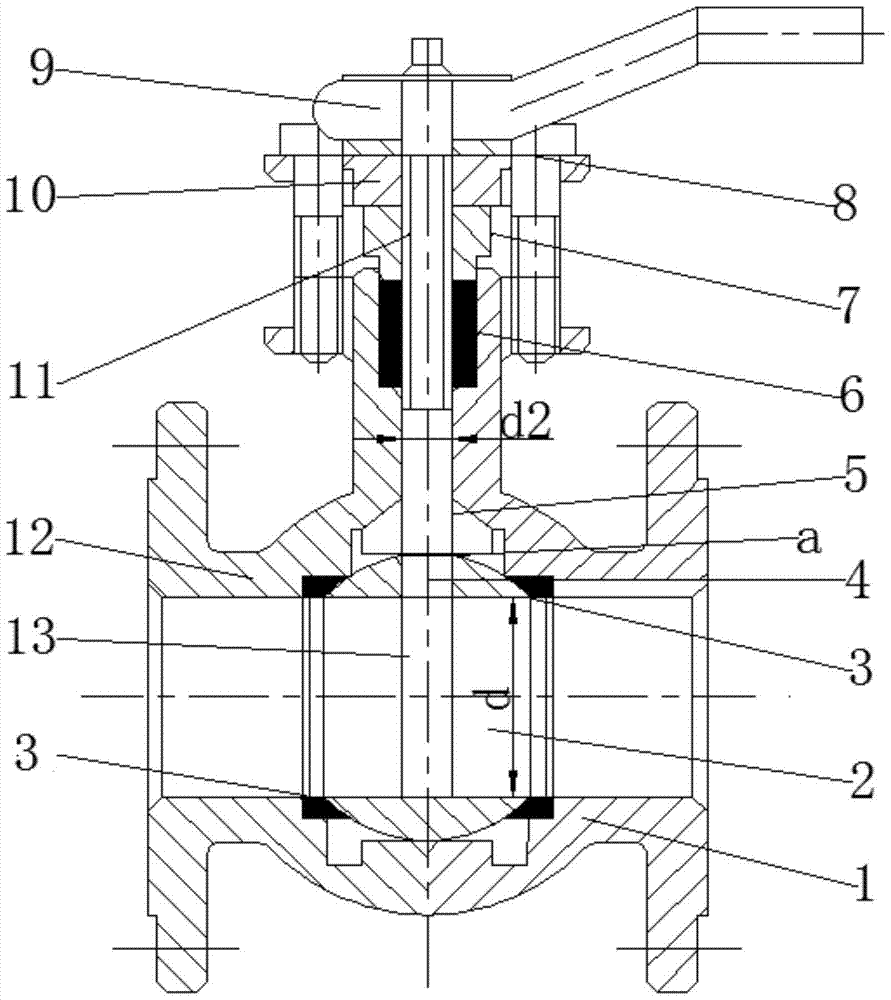

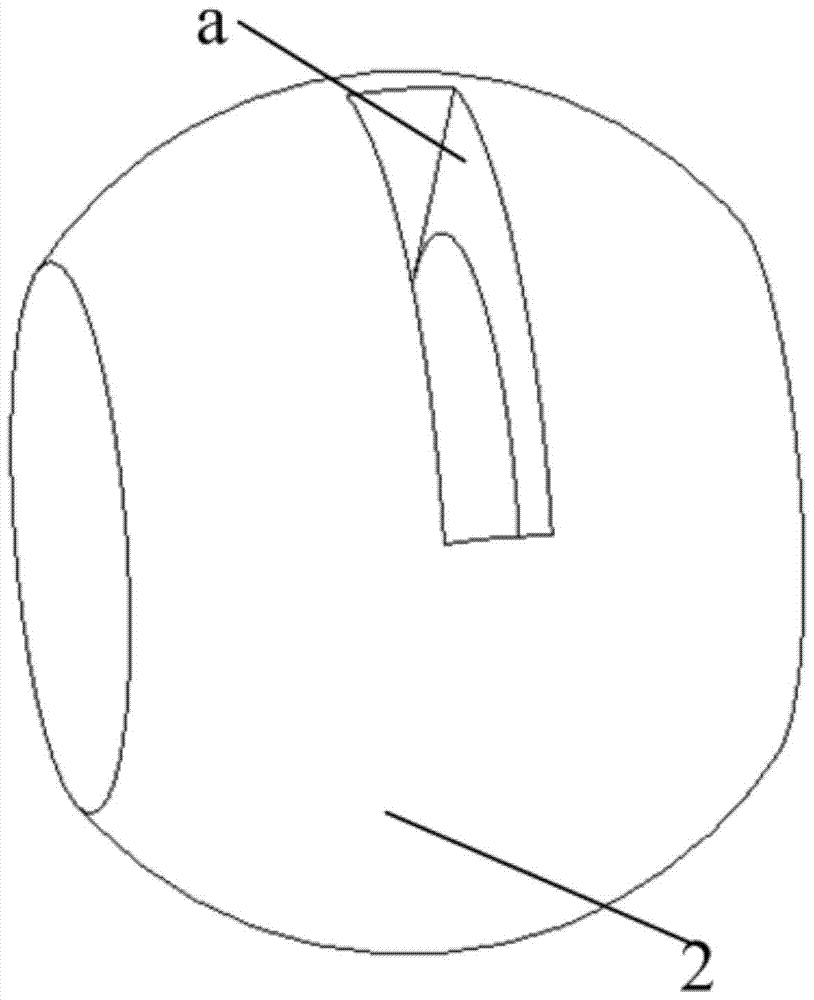

[0022] Such as figure 1 Shown, the present invention comprises right valve body 1, spheroid 2, handle 9 and left valve body 12, and spheroid 2 is housed in right valve body 1 and left valve body 12, and spheroid 2 is connected with right valve body 1 and left valve body 12 respectively. There is a sealing ring 3 between, such as image 3 As shown, there is a through groove a on the upper part of the ball 2, and an inner valve core body for forming the inner valve of the ball valve is also provided between the right valve body 1 and the left valve body 12, and the lower end of the inner valve core body is inserted into the through groove a , the upper end of the inner spool body is fixedly connected with the handle 9.

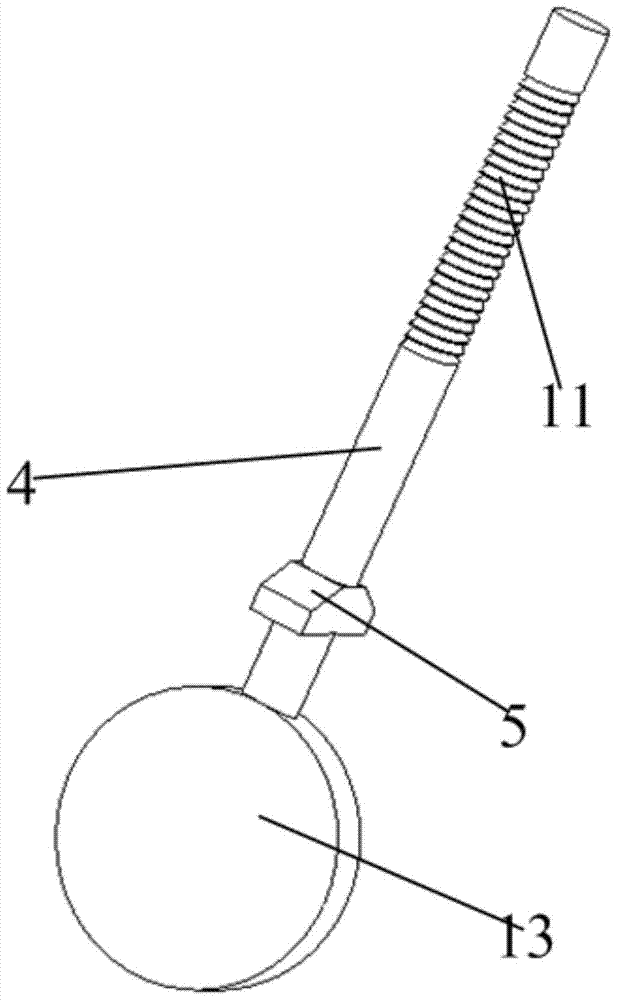

[0023] Such as figure 2 As shown, the upper part of the inner valve core body is a valve stem 4 with threads 11, the lower part of the inner valve co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com