A kind of crucible basket sleeve and preparation method thereof

A technology of crucible and basket cover, which is applied in the field of crucible basket cover and its preparation for vacuum smelting of high-temperature alloys, and can solve the problems of crucible basket cover fusing, failure, and affecting normal smelting production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Manufacturing method of crucible basket cover for 25KG vacuum induction melting furnace

[0031] 1. Calculate the size of the material used for the crucible basket sleeve

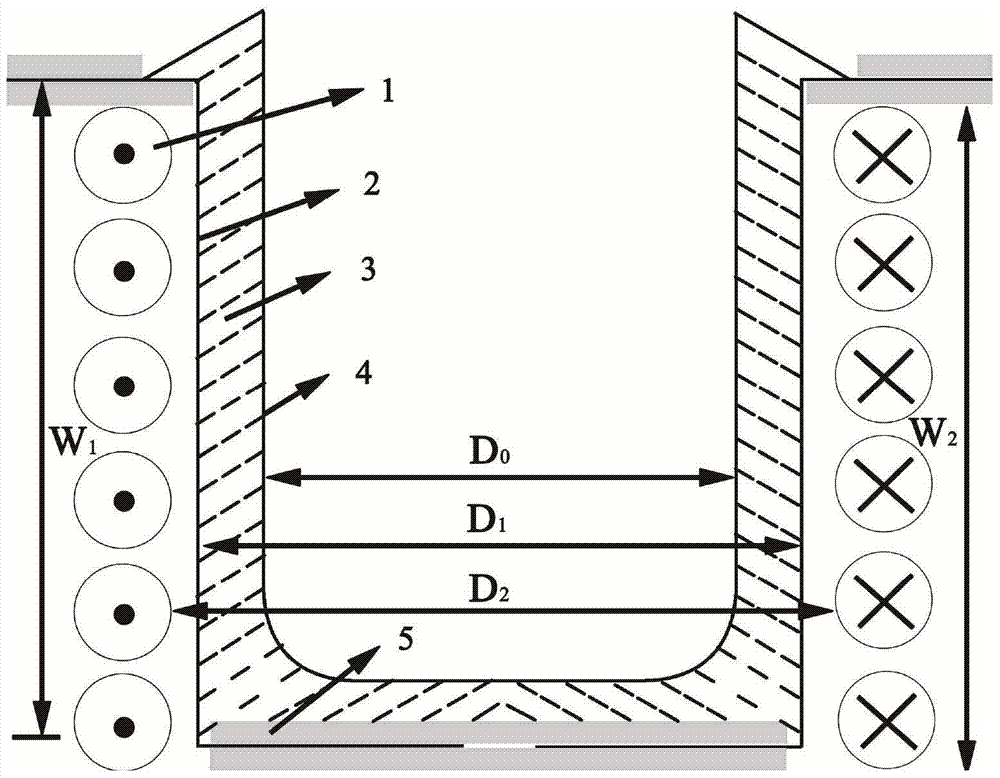

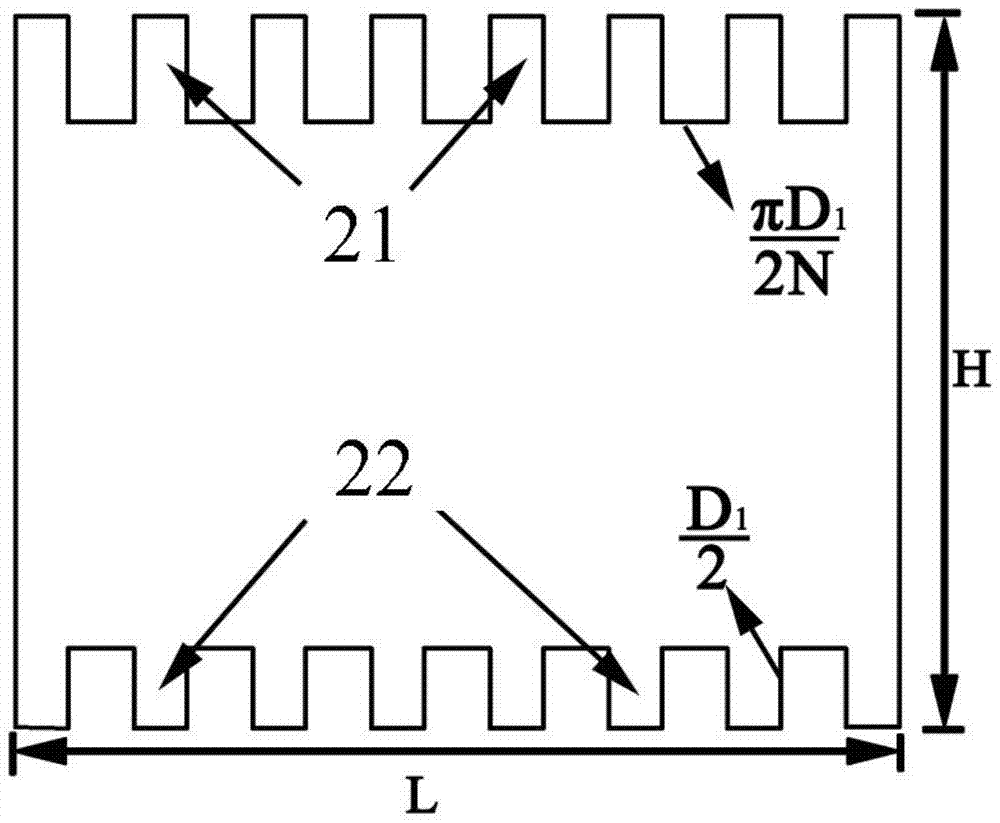

[0032] It is known that the inner diameter of the crucible is D 0 =140mm, height is W 0 =260mm; coil inner diameter D 2 =240mm, height W 2 =300mm; the gap between the crucible and the crucible basket is a=30mm; then the inner diameter of the crucible basket is D 1 =200mm, height W 1 =280mm. Then the length of the steel plate L=670mm, the height of the steel plate H=540mm, such as Figure 4 shown.

[0033] 2. Processing of the upper and lower edges of the crucible basket sleeve

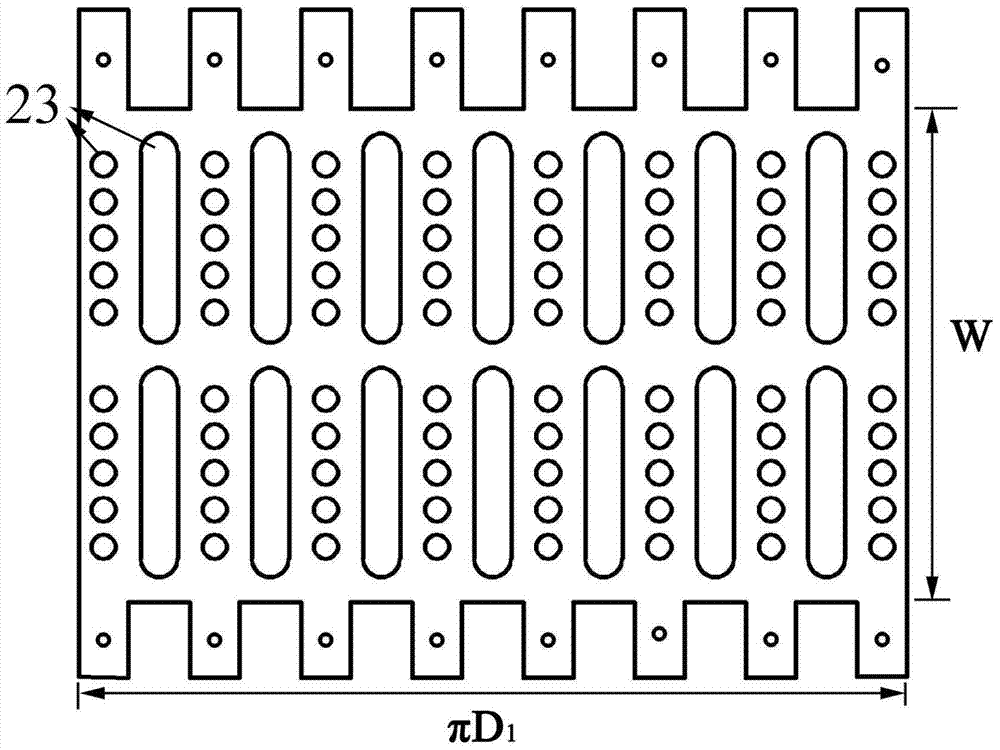

[0034] Carry out 15 equal divisions along the length of the steel plate. Then the width of the fixed upper edge 21 and the fixed lower edge 22 of the crucible basket cover is 40 mm, and the length is 80 mm. Then cut out 7 rectangles at the upper and lower ends of the steel plate at intervals, leaving 8 fixed upper e...

Embodiment 2

[0040] 10KG directional solidification furnace (HRS or LMC) crucible basket making method

[0041] 1. Calculate the size of the material used for the crucible basket sleeve

[0042] It is known that the inner diameter of the crucible is D 0 = 100mm, height is W 0 =220mm; coil inner diameter D 2 =180mm, height W 2 =250mm; the gap between the crucible and the crucible basket is a=25mm;

[0043] Then the inner diameter of the crucible basket D 1 =160mm, height W 1 =240mm; the length L of the steel plate=520mm, the height H of the steel plate=400mm.

[0044] 2. Processing of the upper and lower edges of the crucible basket sleeve

[0045] Carry out 12 equal divisions along the length direction of the steel plate. Then the width of the fixed upper edge and the fixed lower edge of the crucible basket sleeve is 40mm, and the length is 75mm. Then cut out 6 rectangles at intervals at the upper and lower ends of the steel plate, leaving 6 fixed upper edges and 6 fixed lower edg...

Embodiment 3

[0051] Manufacturing Method of Crucible Basket Cover for 50KG Integral Cast Fine Grain Furnace

[0052] 1. Calculate the size of the material used for the crucible basket sleeve

[0053] It is known that the inner diameter of the crucible is D 0 =240mm, height is W 0 =400mm; coil inner diameter D 2 =340mm, height W 2 =500mm; the gap between the crucible and the crucible basket is a=40mm;

[0054] Then the inner diameter of the crucible basket D 1 =320mm, height W 1 =420mm; length L of the steel plate=1000mm, height H of the steel plate=720mm.

[0055] 2. Processing of the upper and lower edges of the crucible basket sleeve

[0056] Carry out 16 equal divisions along the length direction of the steel plate. Then the width of the fixed upper edge and fixed lower edge of the crucible basket sleeve is 60mm, and the length is 150mm. Then cut out 8 rectangles at intervals at the upper and lower ends of the steel plate, leaving 8 fixed upper edges and 8 fixed lower edges.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com