Doppler ultrasonic flowmeter

An ultrasonic and flowmeter technology, applied in the direction of measuring flow/mass flow, liquid/fluid solid measurement, measuring devices, etc., can solve problems such as stagnation of production work, errors in measurement results, inconvenient installation and maintenance of instruments, etc., to achieve easy Effects of setting, increasing precision and stability, speeding up data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

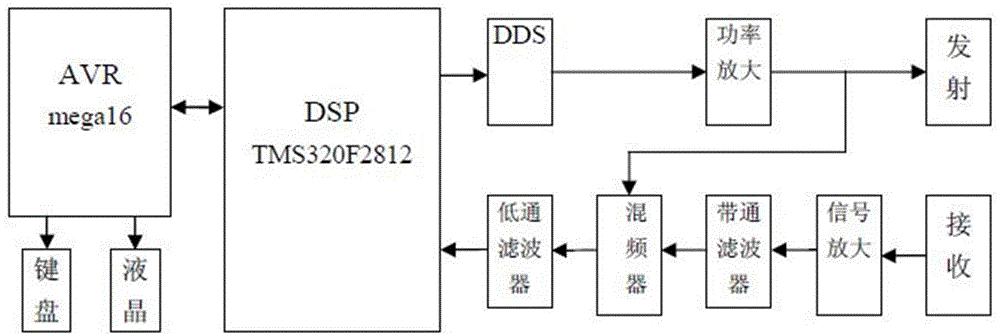

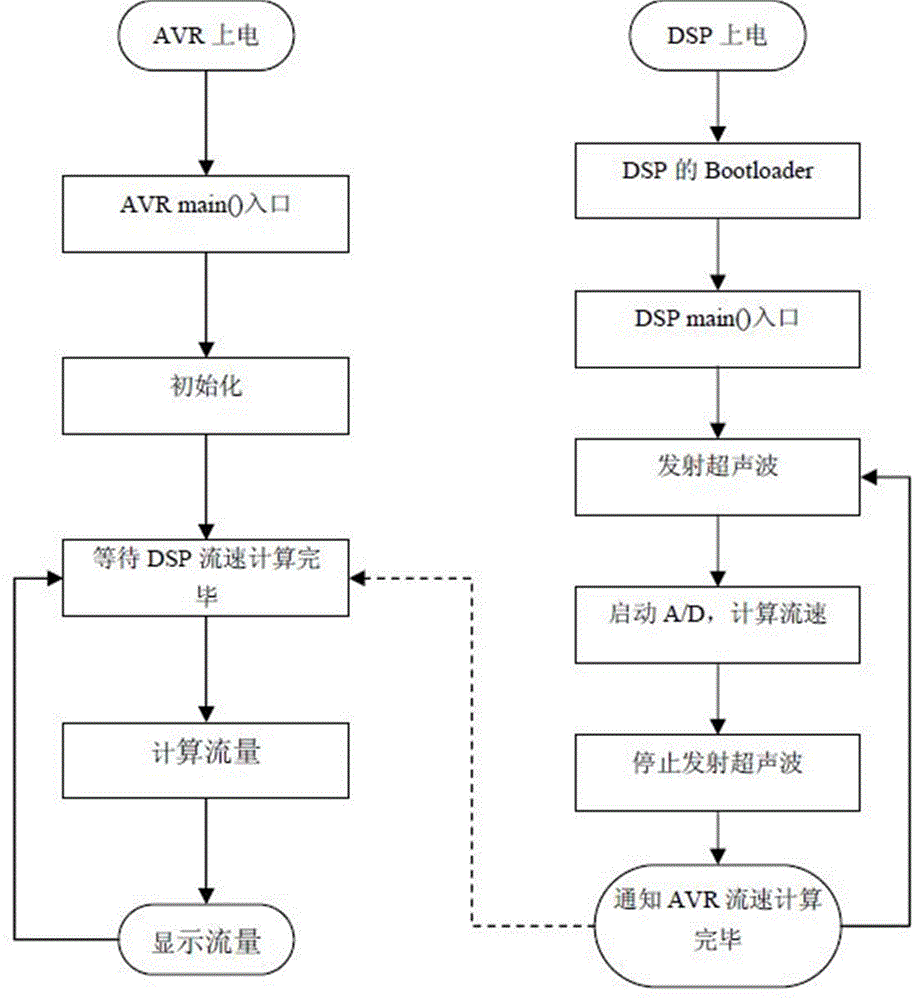

[0015] Such as figure 1 Shown is a hardware block diagram of a Doppler ultrasonic flowmeter system of the present invention. The figure includes a transmitting module, a receiving sampling module, and a processing and control module; the transmitting module includes a DDS circuit, a power amplifier circuit and an ultrasonic transducer, which are connected in sequence; the receiving sampling module includes a signal amplifier circuit, and a belt connected to the amplifier circuit. The pass filter, the mixer connected with the low-pass filter, the low-pass filter connected with the mixer, and the power amplifier circuit is connected with the mixer; the processing and control module is set with DSP chip as the core, including The AVR in which the DSP chips communicate with each other is also provided with a keyboard module and a liquid crystal display module outside the AVR.

[0016] The DDS circuit provided in the transmitting module of the present invention is used to generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com