Method for quantitatively analyzing powder mixture components

A powder mixture, quantitative analysis technology, applied in the analysis of materials, the use of wave/particle radiation for material analysis, measuring devices, etc., can solve the problems of inability to accurately quantitatively analyze the composition of powder mixtures, and the inability to quantitatively analyze the composition of powder mixtures, etc., to achieve The effect of simple method and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

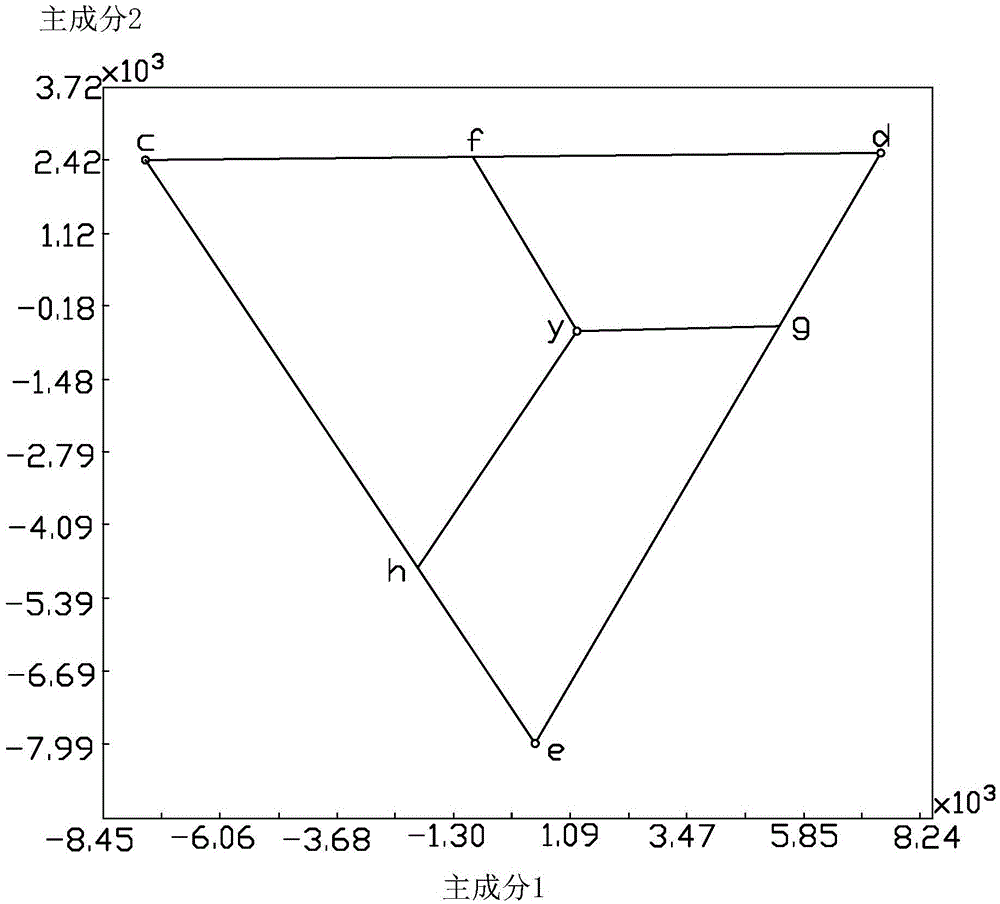

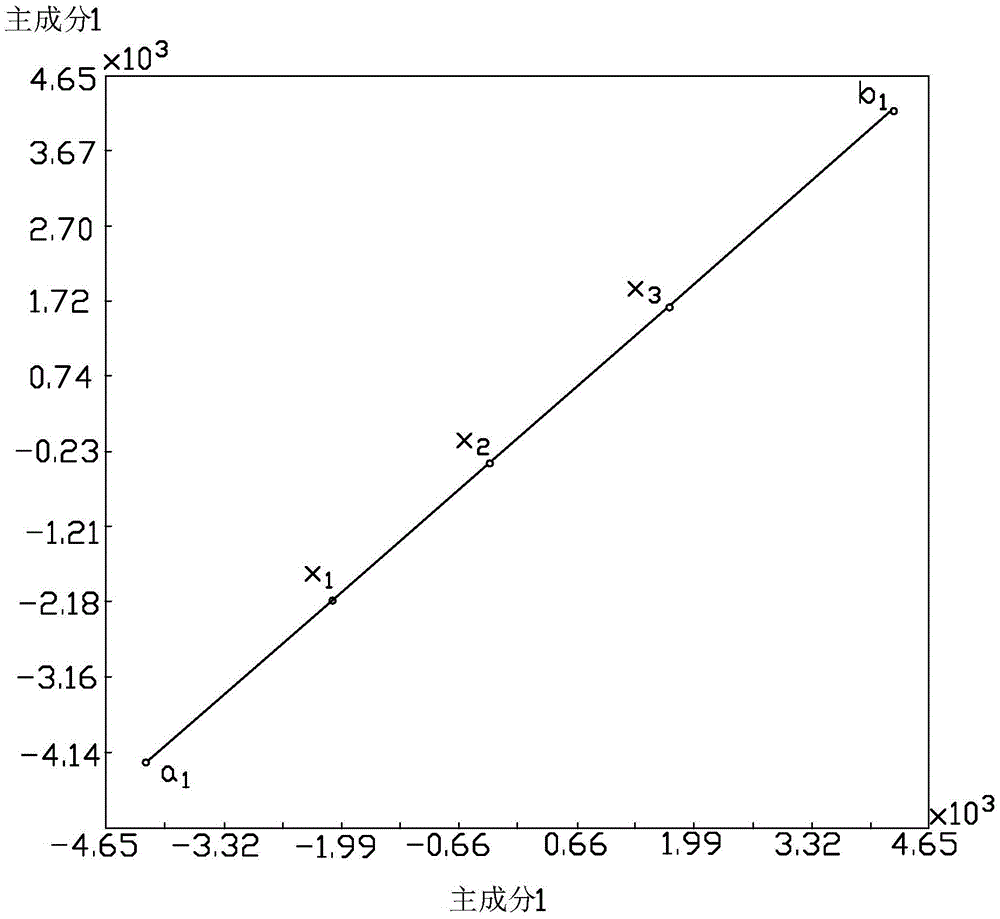

[0056] Provides magnesium oxide (MgO) crystal powder and aluminum oxide (Al 2 o 3 ) 3 kinds of powders to be tested composed of mixed amorphous powder X 1 、X 2 、X 3 , the difference between these three powders to be tested is that the mass percentages of the magnesia crystalline powder and the alumina amorphous powder are different, and the same X-ray diffractometer is used to scan the powder X 1 、X 2 、X 3 Carry out diffraction analysis, the diffraction angle is from 20 degrees to 80 degrees, and the powder X to be tested is obtained at a rate of 4 degrees per minute 1 、X 2 、X 3 X-ray diffraction spectrum; without changing the parameters of the X-ray diffractometer, the diffraction angle is from 20 degrees to 80 degrees, and the X-ray diffraction of magnesium oxide crystal powder and aluminum oxide amorphous powder are respectively obtained at a rate of 4 degrees per minute. Spectrum; all obtained X-ray diffraction spectra are centralized, and the intensity data of the...

Embodiment 2

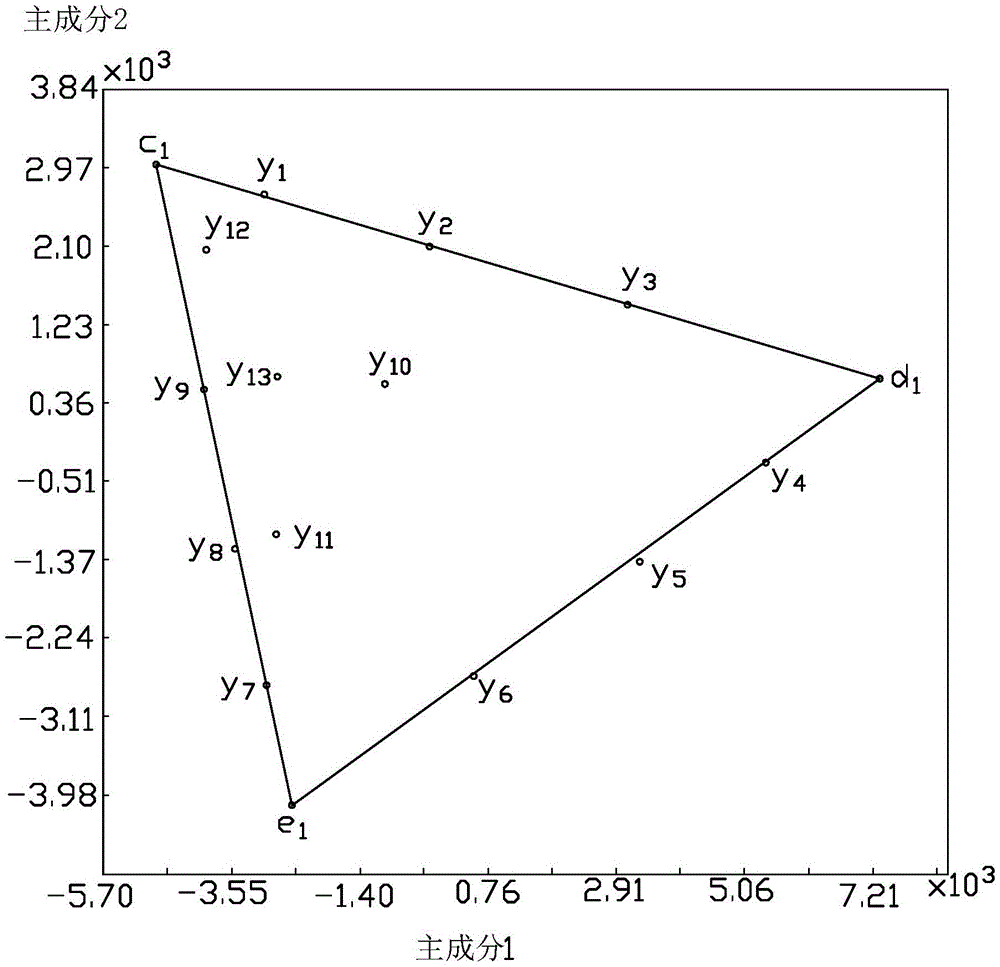

[0063] Provided by titanium oxide (TiO 2 ) crystal powder, zinc oxide (ZnO) crystal powder and cerium oxide (CeO 2 13 kinds of powders to be tested Y composed of at least two kinds of mixtures in ) crystal powder 1 , Y 2 , Y 3 , Y 4 , Y 5 , Y 6 , Y 7 , Y 8 , Y 9 , Y 10 , Y 11 , Y 12 , Y 13 , the difference between the 13 kinds of powders to be tested is only the mass percentages of titanium oxide, zinc oxide and cerium oxide, and the same X-ray diffractometer is used to carry out diffraction analysis on the 13 kinds of powders to be tested in a θ-2θ scanning mode, The diffraction angle is from 20 degrees to 80 degrees, and the X-ray diffraction spectra of the 13 powders to be tested are respectively obtained at a rate of 4 degrees per minute; without changing the parameters of the X-ray diffractometer, the diffraction angle is from 20 degrees to 80 degrees. degrees, respectively obtain the X-ray diffraction spectra of titanium oxide crystal powder, zinc oxide crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com