A method for the determination of methyl vanillin and ethyl vanillin in milk powder using headspace-solid phase microextraction

A technology of methyl vanillin and ethyl vanillin, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high detection limit, cumbersome steps, and low recovery rate, so as to avoid false positives and improve sensitivity , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

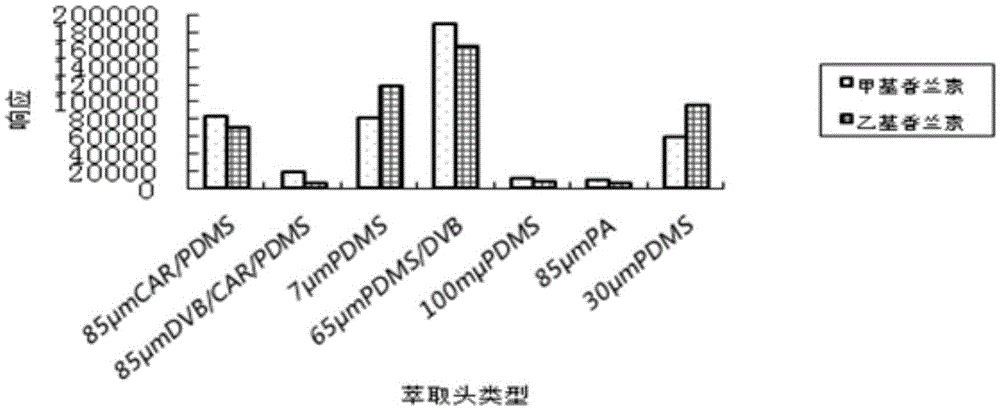

[0071] Embodiment 1: selection experiment of extraction fiber type

[0072] According to the principle of similar miscibility, the non-polar fiber coating has a higher extraction efficiency for non-polar compounds, while the polar fiber coating has a higher extraction efficiency for polar compounds. Under the conditions of 70°C, oscillator speed 500r / min, equilibration 10min, and headspace solid-phase microextraction 20min, the extraction effects of 7 different types of extraction fibers on the matrix standard mixture were investigated. figure 1 It is a comparison chart of the extraction effects of 7 different types of extraction fibers on the matrix standard mixture. The extraction capabilities of the seven extraction fibers were compared from three aspects: the amount of extracted methyl vanillin and ethyl vanillin (expressed by peak area), the resolution of chromatographic peaks and the peak shape. figure 1 The results show that: the peaks of the target components obtained...

Embodiment 2

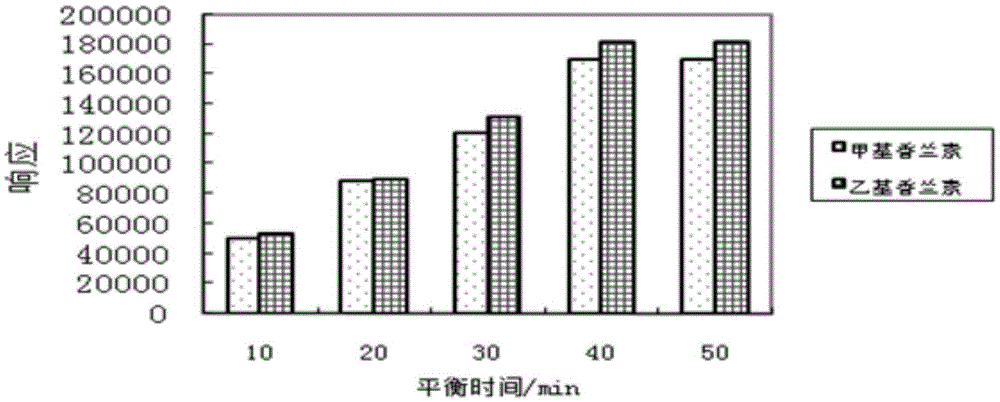

[0073] Embodiment 2: Optimization experiment of balance time

[0074] Preheat the sample to achieve gas-liquid equilibrium. Controlling other conditions unchanged, the test investigated the peak area changes of methyl vanillin and ethyl vanillin when the equilibrium time was 10, 20, 30, 40, and 50 min respectively. figure 2 It is the graph of the optimization experiment result of the equilibration time. Such as figure 2 As shown in the results, within the investigated time, the peak area of the target compound increases with time. When the equilibration time is longer than 40min, increasing the equilibration time, the increase of the peak area does not change much, indicating that the equilibration is 40min, and the gas-liquid equilibrium has been reached. Therefore, 40min was chosen as the optimal equilibration time.

Embodiment 3

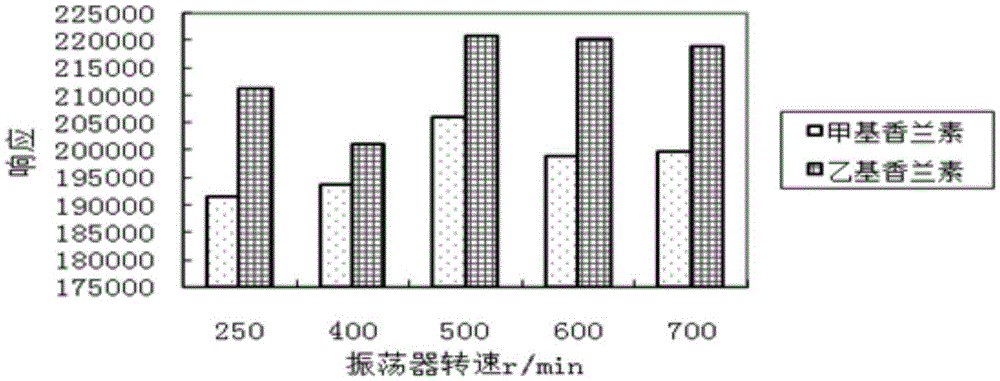

[0075] Embodiment 3: Optimization experiment of oscillator speed

[0076] Controlling other conditions unchanged, the effects of 250, 400, 500, 600, and 700 r / min on the peak area of the target compound were investigated respectively. image 3 is the graph of the optimized experimental results of the oscillator speed, by image 3 It can be seen that the larger the rotational speed, the larger the target peak area. This is because increasing the stirring speed can not only accelerate the speed of the extracted substance entering the gas phase, but also strengthen the flow of the upper gas, which is beneficial to the transfer of the extracted substance in the gas and improves the extraction efficiency of the analyte. After the rotational speed is greater than 500r / min, the peak area basically no longer shows an increasing state, so this method selects a rotational speed of 500r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com