Strong current short-circuit testing transformer with air gaps and implementation method therefor

A technology of short-circuit test and implementation method, which is applied in the field of transformer manufacturing, can solve problems such as failure to meet standard requirements, affect test voltage, and current waveform output, and achieve the effect of reducing magnetic saturation of iron core and reducing residual magnetism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

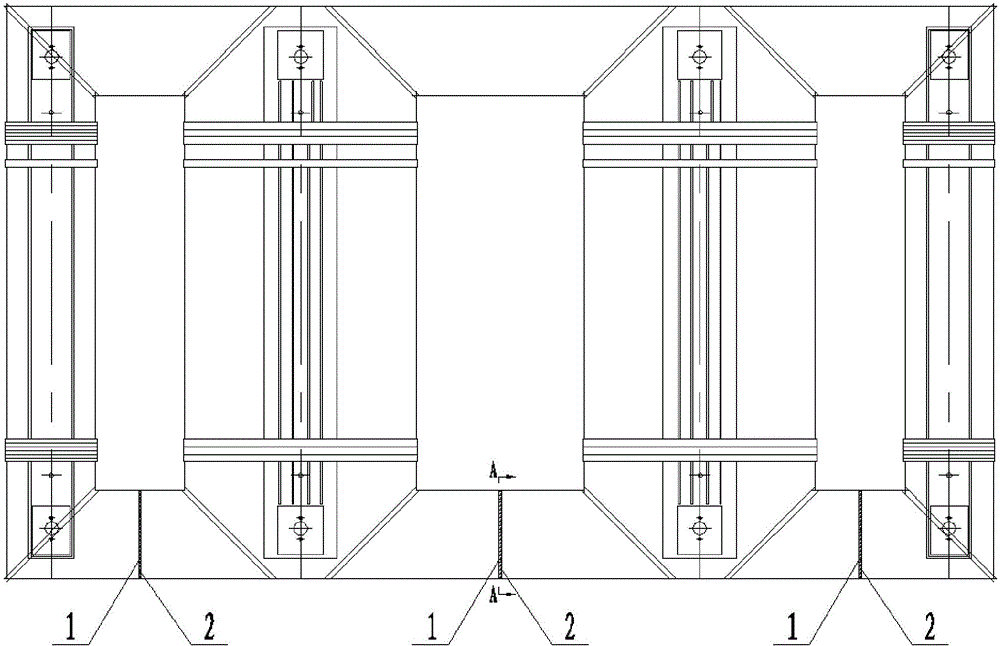

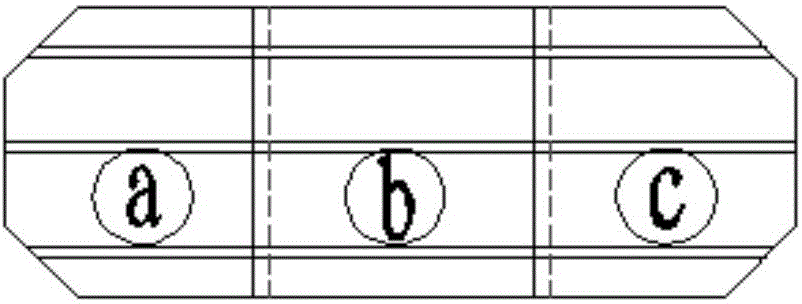

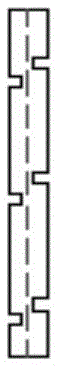

[0029] Such as Figure 1~4 As shown, a high-current short-circuit test transformer with an air gap in the present invention has four iron core columns, and an air gap is left on the lower cross yoke between every two iron core columns, that is, the iron yoke air gap 1, and the iron core column An insulating plate 2 is filled in the yoke air gap 1, and a copper shield 3 is installed on the web corresponding to the iron yoke air gap 1; an insulating pull belt 4 that can support the insulating plate 2 is provided at the lower part of the iron yoke air gap 1; the insulating On the front and back sides of the plate 2, there are oil passages in the horizontal direction, and the oil passage groove direction of the insulating plate 2 is perpendicular to the stacking direction of the silicon steel sheet. The laid oil passages are connected; the silicon stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com