Steady flow and multi-purpose silica sand pump pool

A pump pool and silica sand technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of large size of classifier, difficult to install pump pool, time-consuming and labor-intensive, etc., so as to improve work efficiency and work performance. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

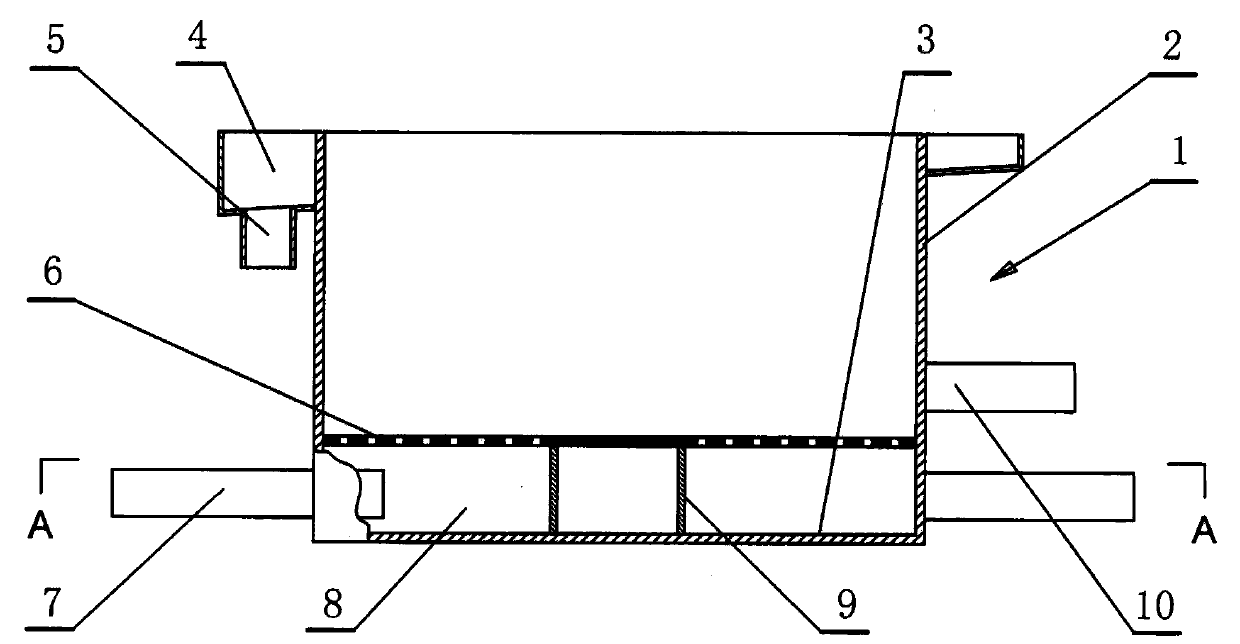

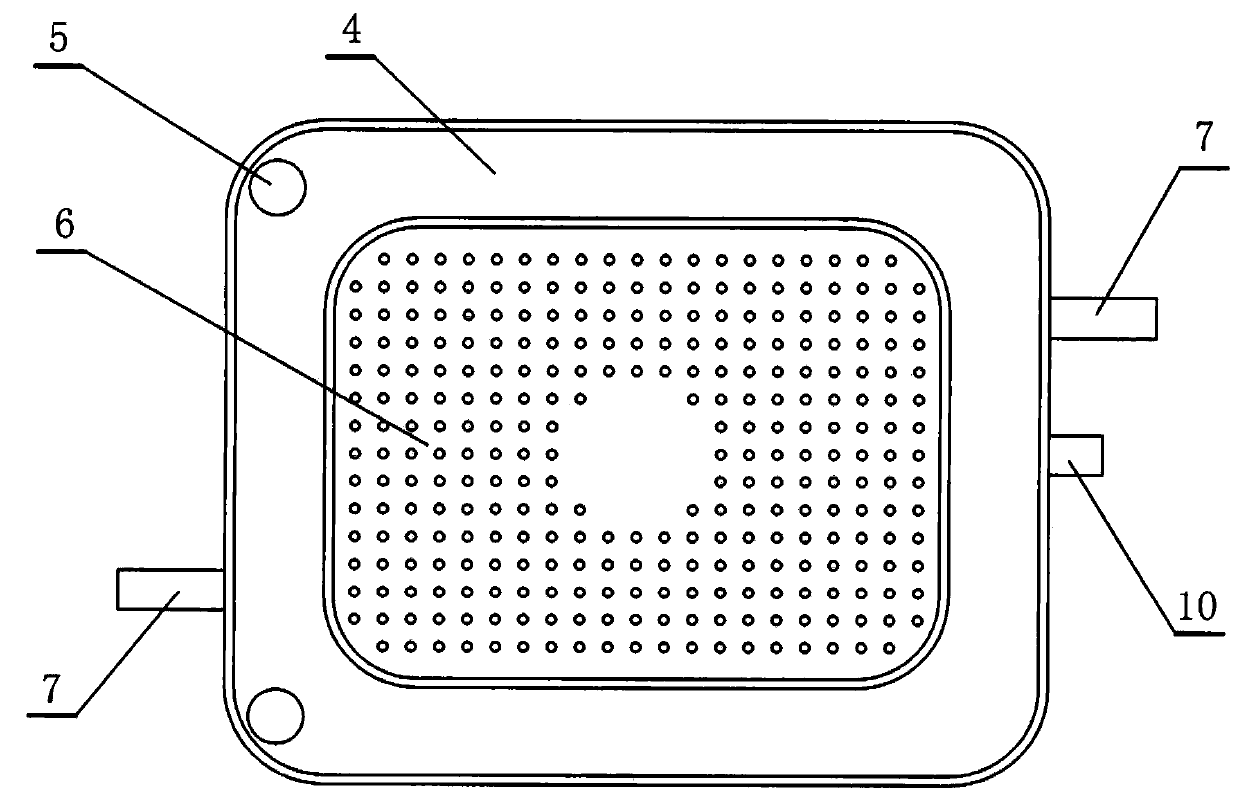

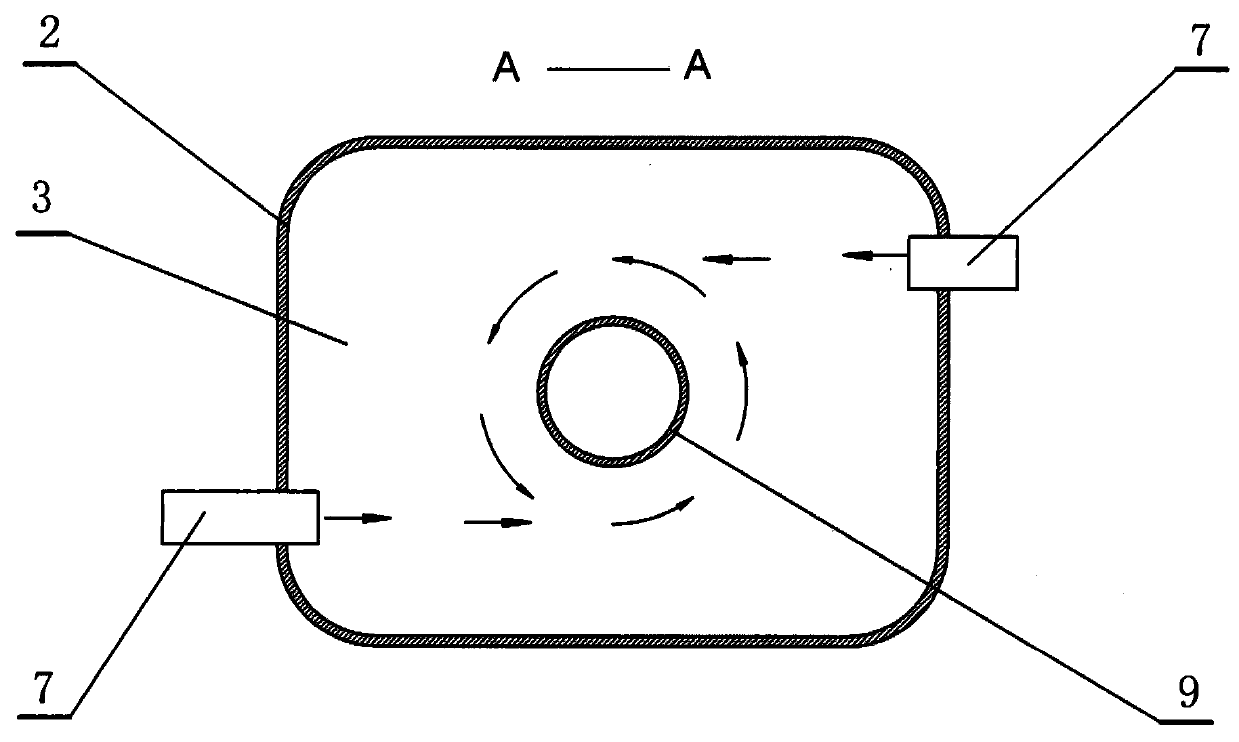

[0032] The general idea of the present invention is to install a diversion device at the bottom of the pump pool, so that the incoming water rotates around the center and rises steadily, which is beneficial to the separation of materials with different specific gravity. Four embodiments are described below in conjunction with the accompanying drawings.

[0033] The first embodiment: as figure 1 figure 2 As shown, this steady flow multi-purpose silica sand pump pool is a pump pool 1 surrounded by pool walls 2 and pool bottom 3. The upper periphery of the pump pool 1 is provided with an annular overflow tank 4, and the bottom surface of the overflow tank 4 is inclined. The lowest part is provided with an overflow port 5. The lower part of the pump pool 1 is provided with a water inlet pipe 7, and the upper part of the water inlet pipe 7 is provided with a perforated plate 6. It is characterized in that: between the pool bottom 3 and the perforated plate 6 is a circulation c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com