Cast tube inner wall cleaning device

A technology for cleaning devices and casting pipes, which is applied in the direction of used abrasive processing devices, explosion generating devices, and abrasive feeding devices, etc., which can solve problems such as short replacement cycles, affect production rhythm, and increase steel grit consumption, etc., to achieve Reduce the loss of steel grit, do not affect the production rhythm, and achieve significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

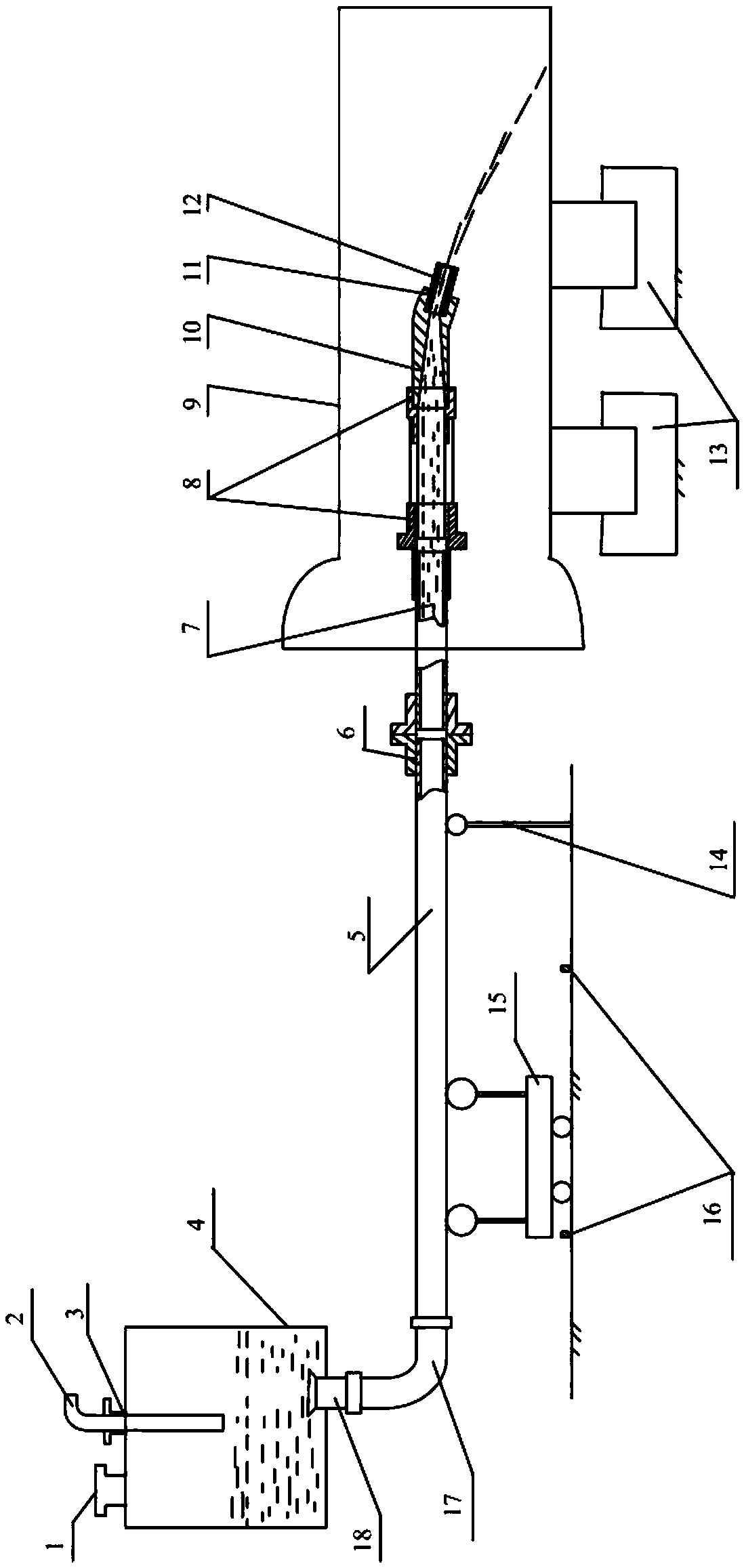

[0021] As shown in the accompanying drawings, the cast pipe inner wall cleaning device includes a sealed tank 4, a steel pipe 5, a shaft coupling 6, a spray gun head, a support roller group 13, a support frame 14 and a mobile trolley 15; The upper part is processed with a sand inlet 1 and a nitrogen inlet 2; the lower part of the sealed tank 4 is equipped with a nitrogen outlet 18; the nitrogen outlet 18 is connected to the steel pipe 5 through a hose 17; the steel pipe 5 is connected to the spray gun through a coupling 6 The nozzle part of the spray gun head extends into the cast pipe 9 on the upper part of the support roller group 13; the end of the steel pipe 5 near the coupling is supported by the support frame 14, and the middle part is supported by the mobile trolley 15 and moves along with it. The moving trolley 15 advances and retreats; the steel grit 7 is blown from the steel pipe into the spray gun head through the nitrogen flow, and then blown out by the spray gun he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com