Traction beam

The technology of traction beam and reinforcing beam is applied in the field of rail car body manufacturing, which can solve the problems of complicated installation and connection between the traction beam and the coupler, unfavorable lightweight design of the car body, and large own weight, and achieves reasonable force transmission and reduction of welding heat input. , The effect of reducing the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

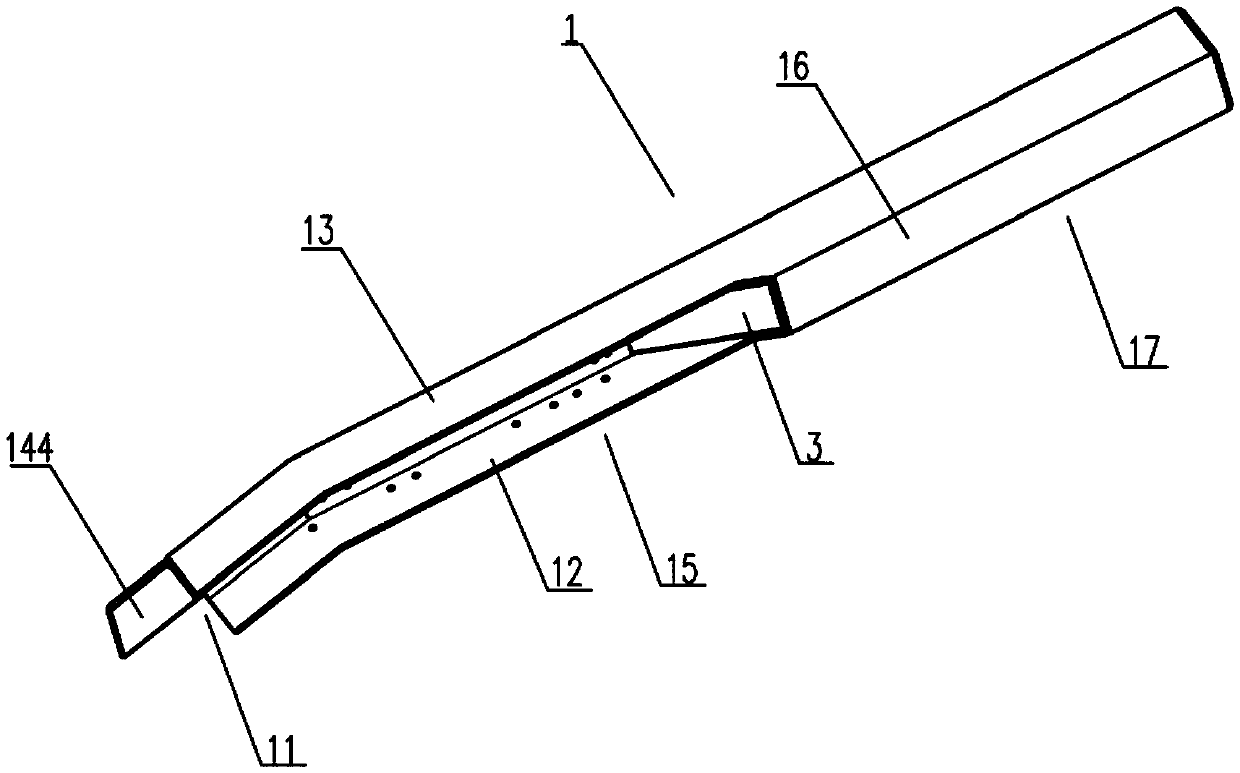

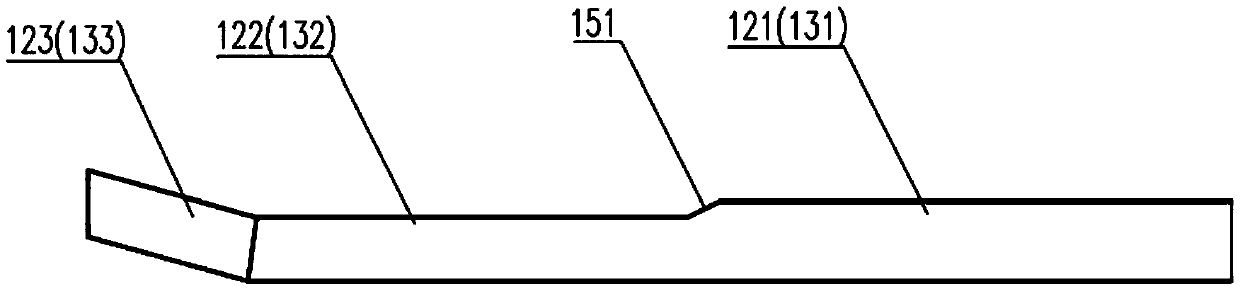

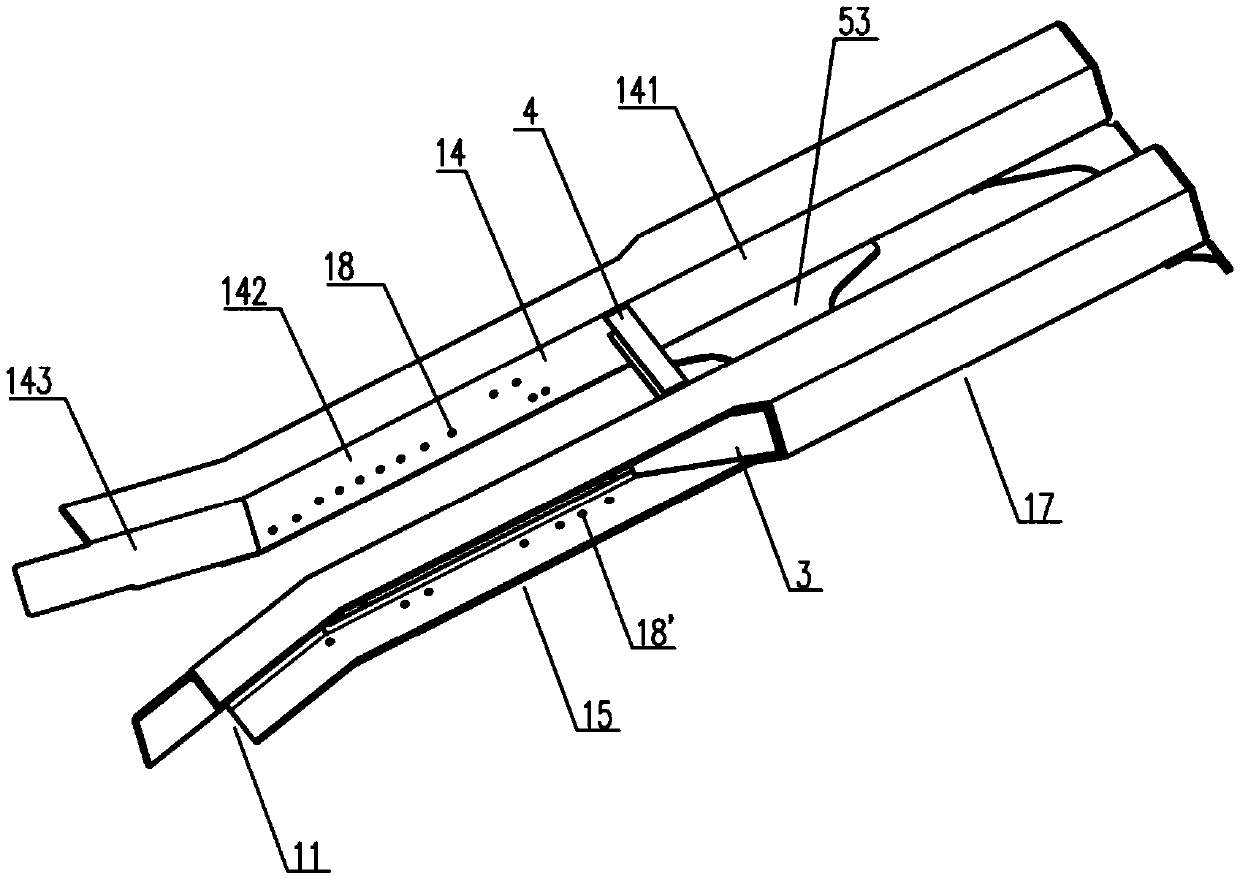

[0034] The drawing beam of the present invention will be described below in conjunction with the accompanying drawings.

[0035] Such as Figure 1-4 As shown, the traction beam of the present invention includes two traction beam single pieces 1 arranged side by side, and the front ends of the two traction beam single pieces 1 are respectively provided with bending parts 11 bent in opposite directions, so that The front end of the traction beam forms a bell mouth 2 , the front end of the traction beam 1 is connected to the vehicle body buffer beam 7 , and its rear end is connected to the corbel 8 .

[0036] Preferably, the front end of the traction beam 1 is welded to the vehicle body buffer beam 7 , and its rear end is welded to the corbel 8 .

[0037] In a preferred embodiment of the present invention, the traction beam single piece 1 is an integrally formed structure.

[0038] More preferably, the single part of the traction beam is a full-length 6-series welded profile, m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com