Brick pile intersected caging and gathering device

A cage and brick pile technology, which is applied in the field of brick pile fork and cage folding device, can solve the problems of low work success rate, low work efficiency, and inability to carry out overall transportation, so as to improve work efficiency, facilitate unloading and transportation, and brick pile tight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

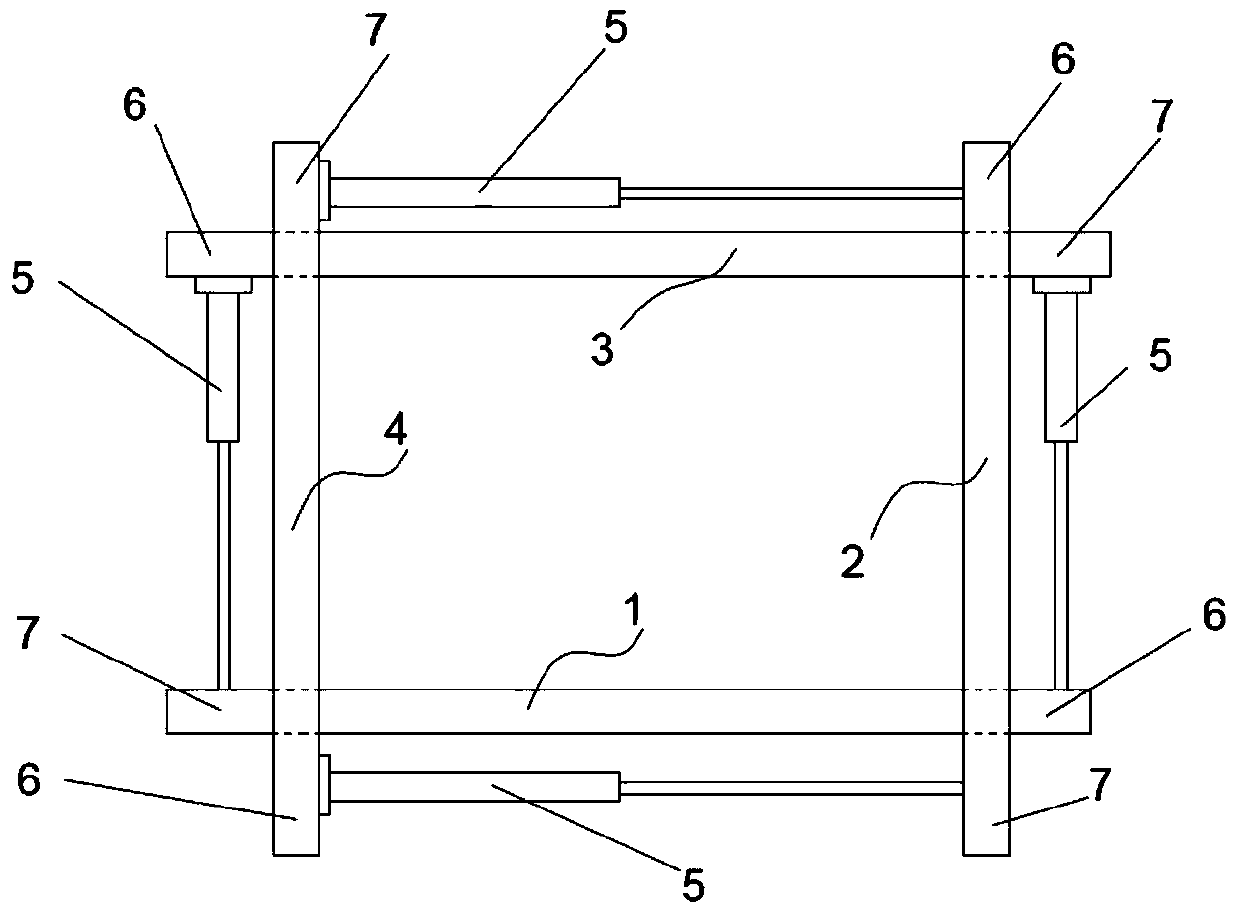

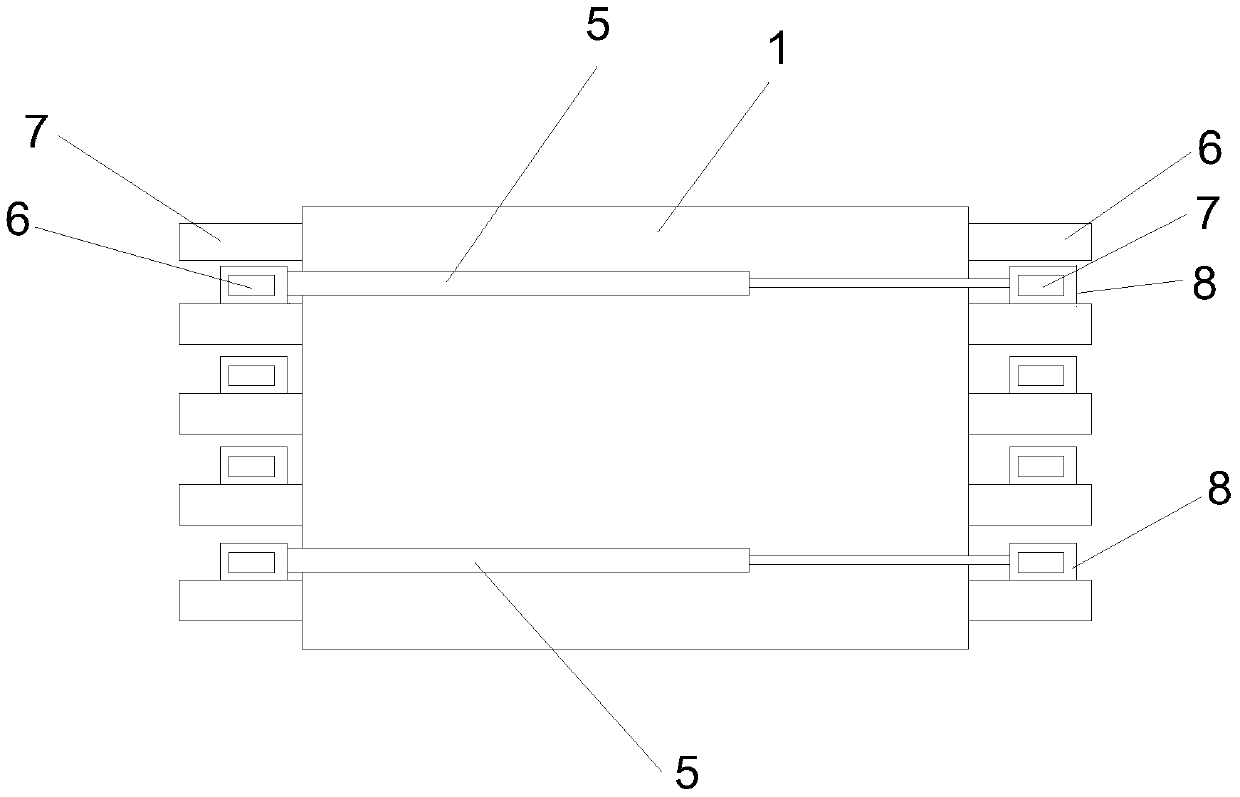

[0030] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

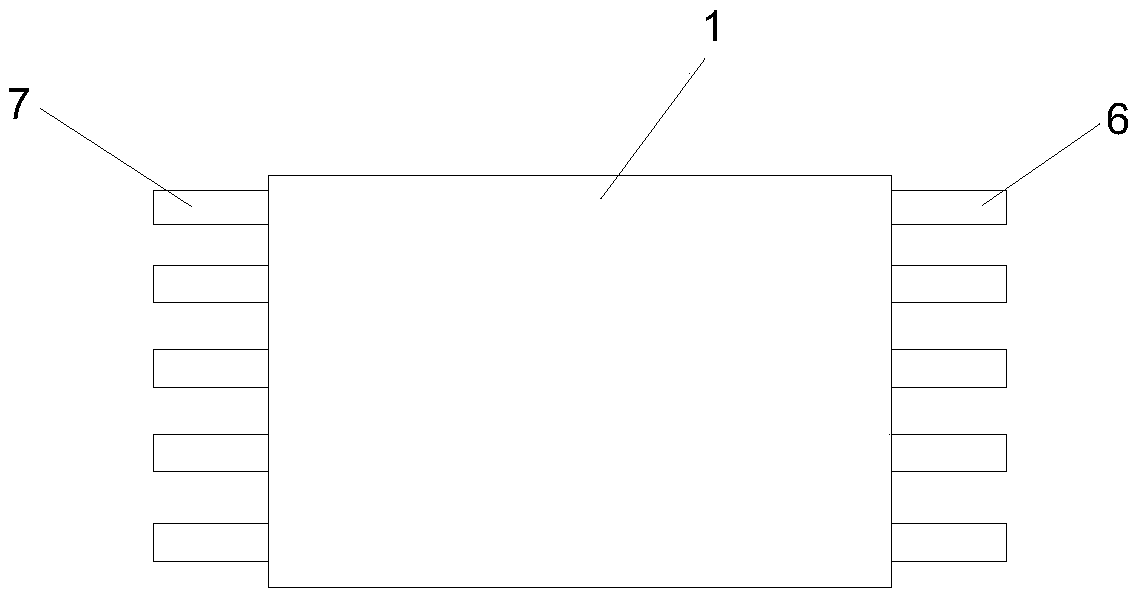

[0031] Such as figure 1 and figure 2 As shown, the present invention provides a kind of brick heap fork closes the enclosure gathering device, comprises the first to four surrounding cage plates (1, 2, 3 and 4) and gathering device 5; Said first surrounding cage plate 1 and said third The cage boards 3 are relatively arranged, and the second cage board 2 is arranged opposite to the fourth cage board 4; the first cage board 1, the second cage board 2, the third cage board The cage plate 3 and the fourth cage plate 4 are connected end to end in turn to form a cage with an adjustable opening size; the cage is set on the outer periphery of the brick pile, and the gathering device 5 is used to gather the cage to eliminate the gap in the brick pile. Clearances to obtain solid brick piles.

[0032] One end surface of each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com