A bobbin tail yarn processing device and processing method

A technology for processing equipment and tail yarns, which is applied in the direction of thin material handling, delivery of filamentous materials, transportation and packaging, etc. It can solve problems such as incomplete removal of tail yarns, deformation of the hanging spindle conveyor chain, and influence on roving winding, etc., to achieve Achieve automatic cleaning, simple and compact structure, and save manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

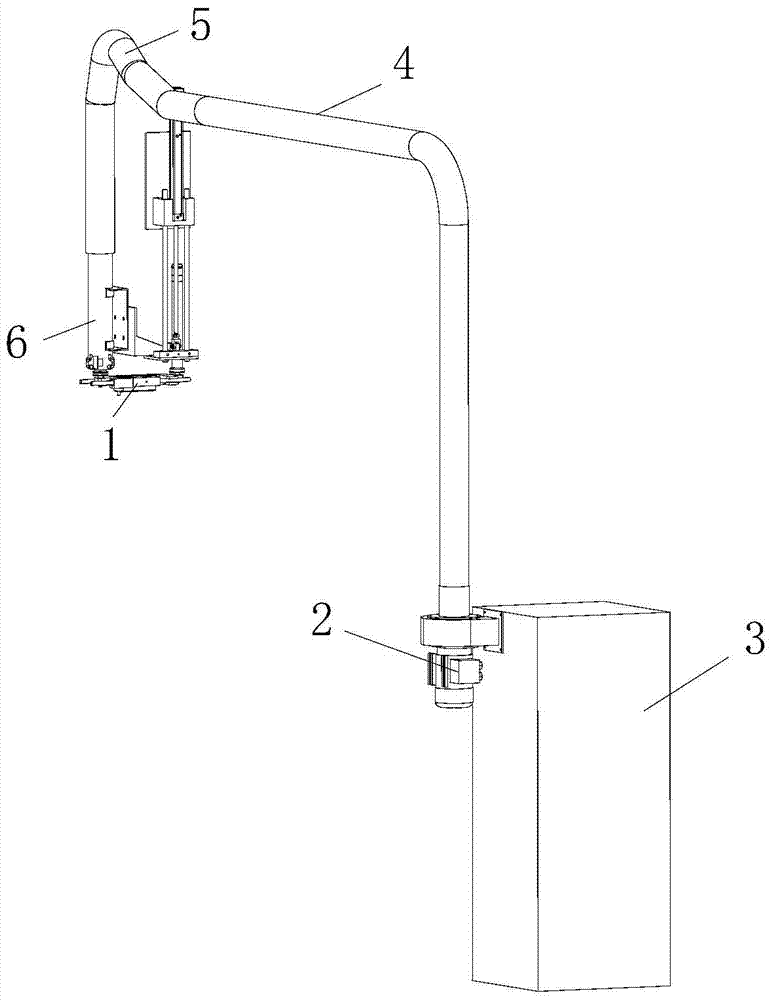

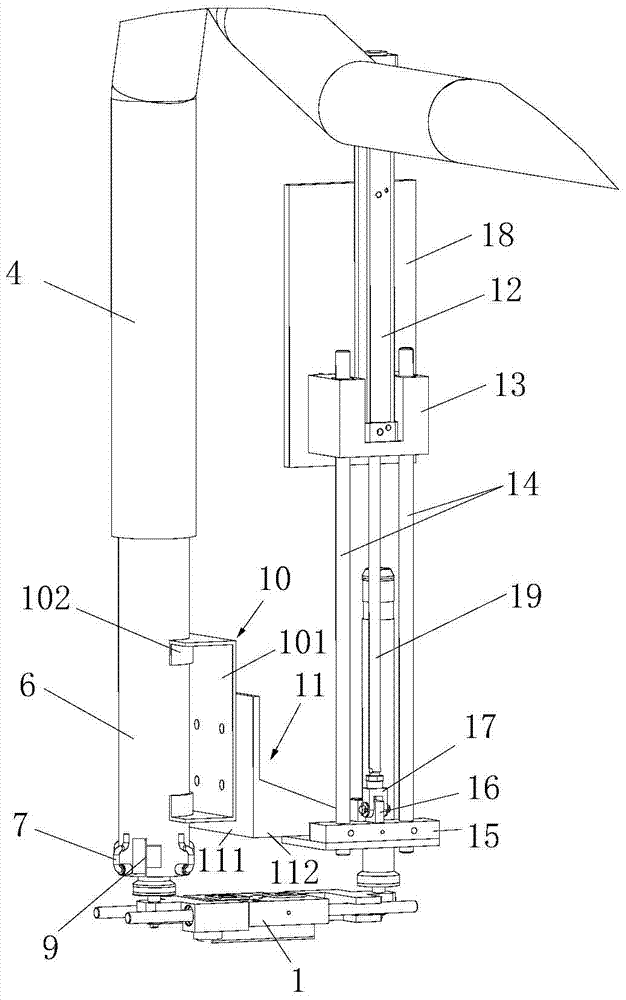

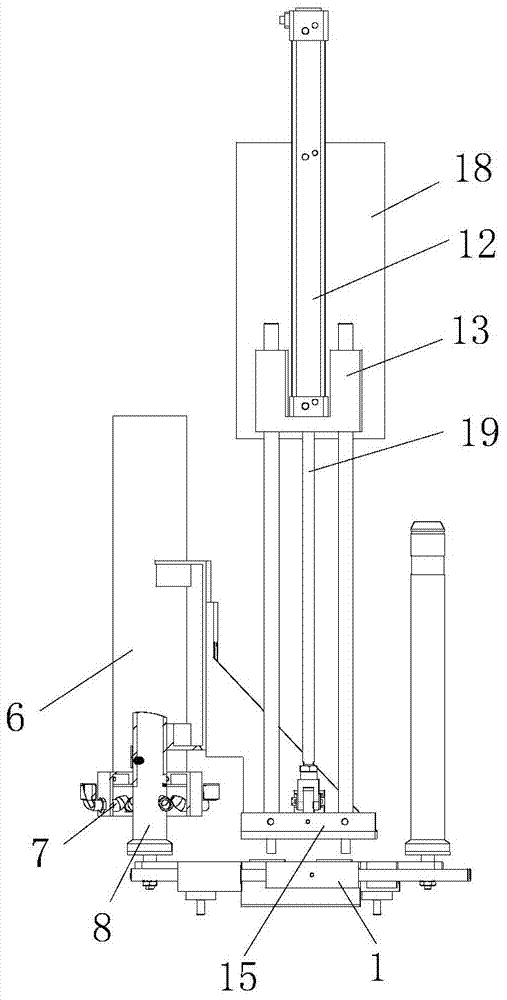

[0033] Such as Figure 1 to Figure 3 As shown, a bobbin tail yarn processing equipment includes a switch 1 and a tail yarn clearing device, an empty yarn bobbin 8 withdrawn from the spinning frame is vertically placed on the switch 1, and the tail yarn clearing device includes an air duct 4, which is arranged on The suction fan 2 at the end of the air duct 4, the cover tube 6 capable of wrapping the empty yarn tube 8 and the lifting mechanism that drives the cover tube 6 to move up and down, the air tube 4 is connected with the cover tube 6, and the diameter of the cover tube 6 is smaller than that of the air duct 4, when the cover tube 6 moves up and down, it moves along the diameter of the air duct 4, and the corners of the air duct 4 are provided with corrugated hoses 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com