Equipment for manufacturing LED (Light-Emitting Diode) lamp tube

An LED lamp and lamp technology, which is applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of short service life of LED lamps, easy falling off of LED strips, complicated installation process, etc. Small, compact connection, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with the accompanying drawings.

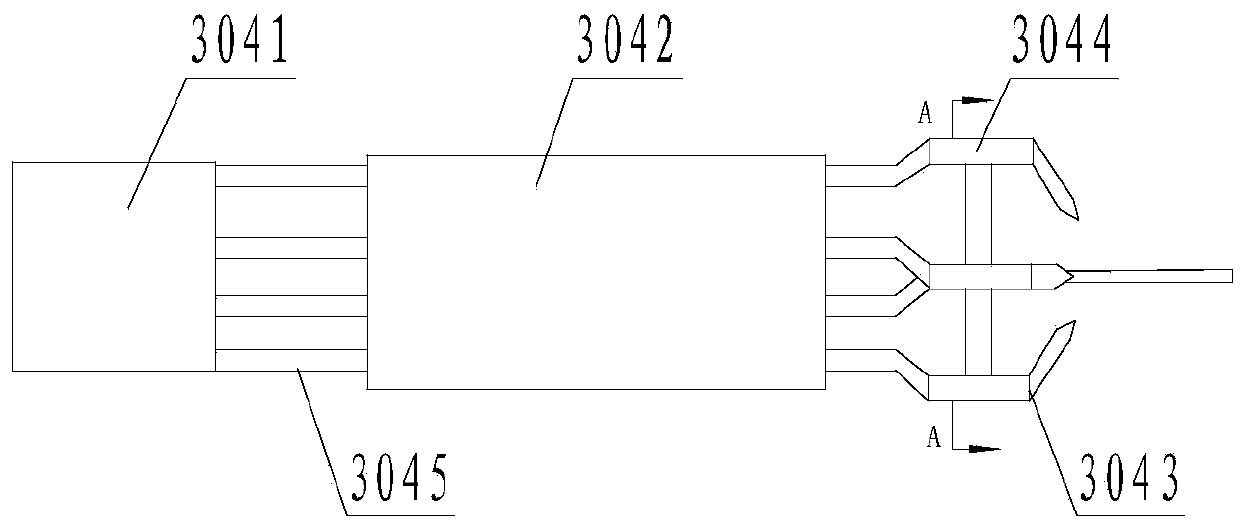

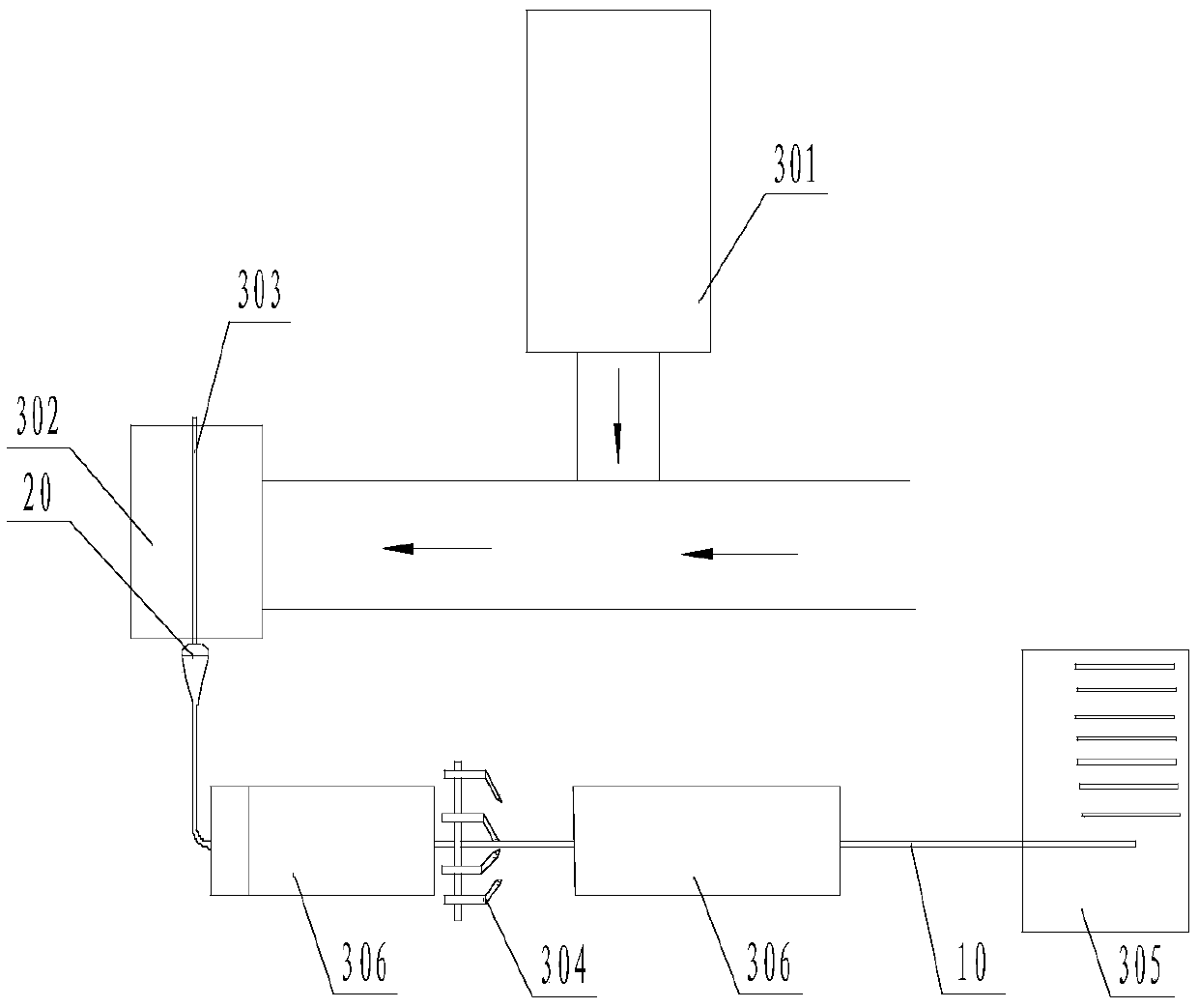

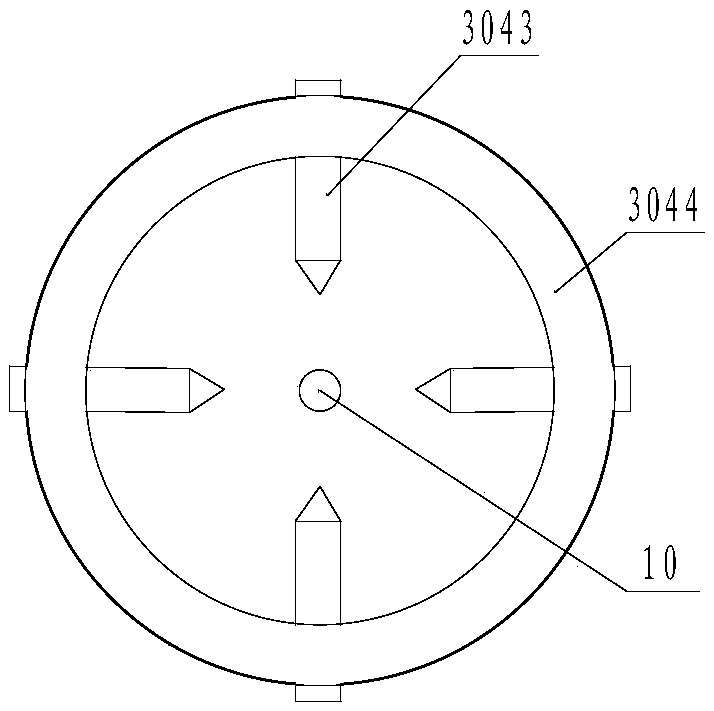

[0024] A device for making LED light tubes, such as figure 1 As shown, it includes a glass furnace 301, a homogenizing cylinder 302, a lamp tube mold 20, a lamp tube conveying device 306, a stress relief device 304 and a pipe cutting device 305; the glass furnace 301 and the homogenizing cylinder 302 are connected by pipelines, A blowing tube 303 is arranged in the uniform material cylinder 302, and the blowing tube 303 is connected to the lamp tube mold 20. A lamp tube conveying device 306 is arranged under the lamp tube mold 20. The lamp tube conveying device 306 is provided with a conveying wheel. A sealing cover is provided, and the newly formed lamp tube 10 is sealed inside the sealing cover and transported under negative pressure; the lamp tube conveying device 306 transports the initially formed lamp tube 10 to the tube cutting device 305, and the tube cutting d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com