Synthesis method of methacrylaldehyde

A technology for synthesizing methacrolein and isobutylene, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve problems such as low yield of methacrolein, and achieve good technical effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

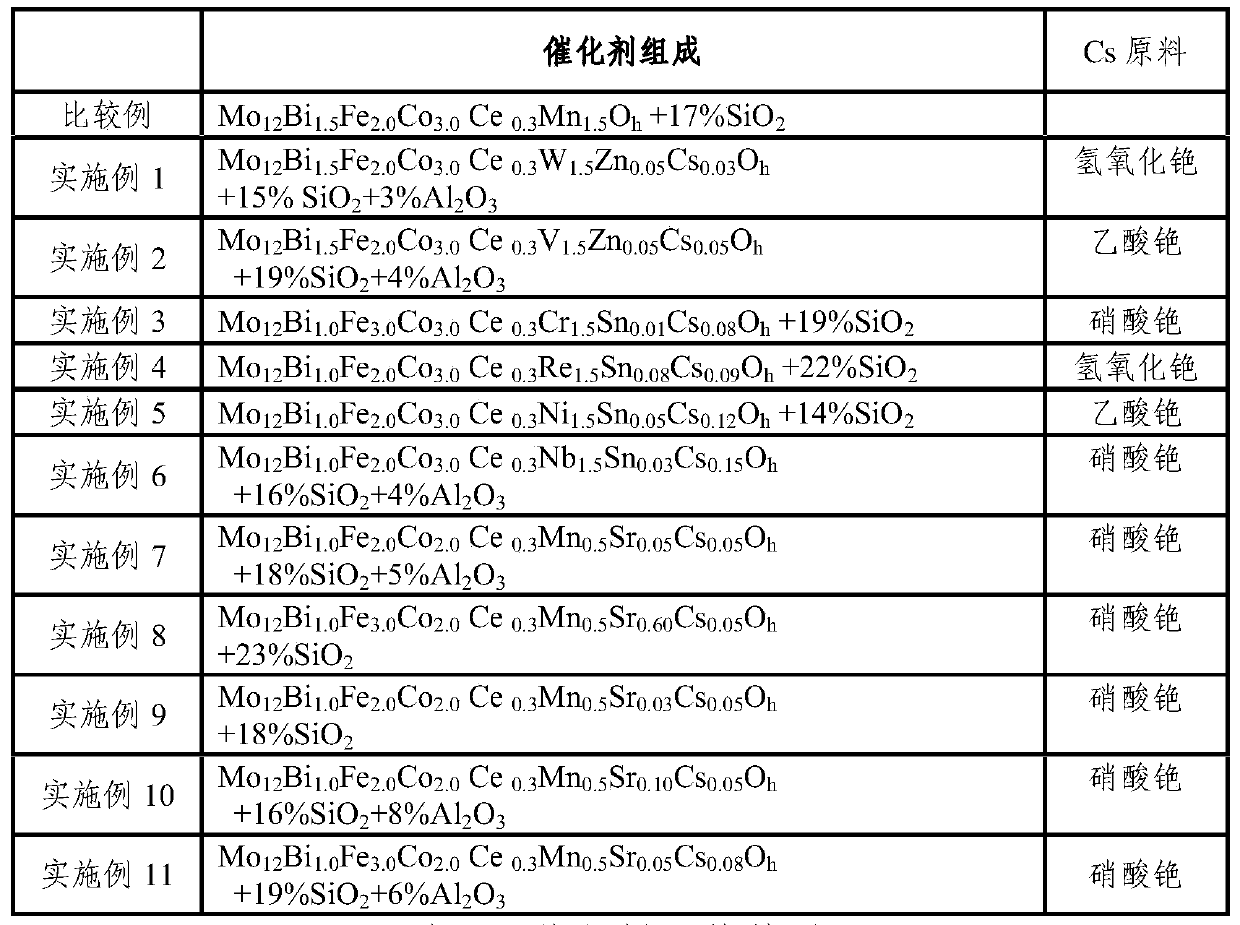

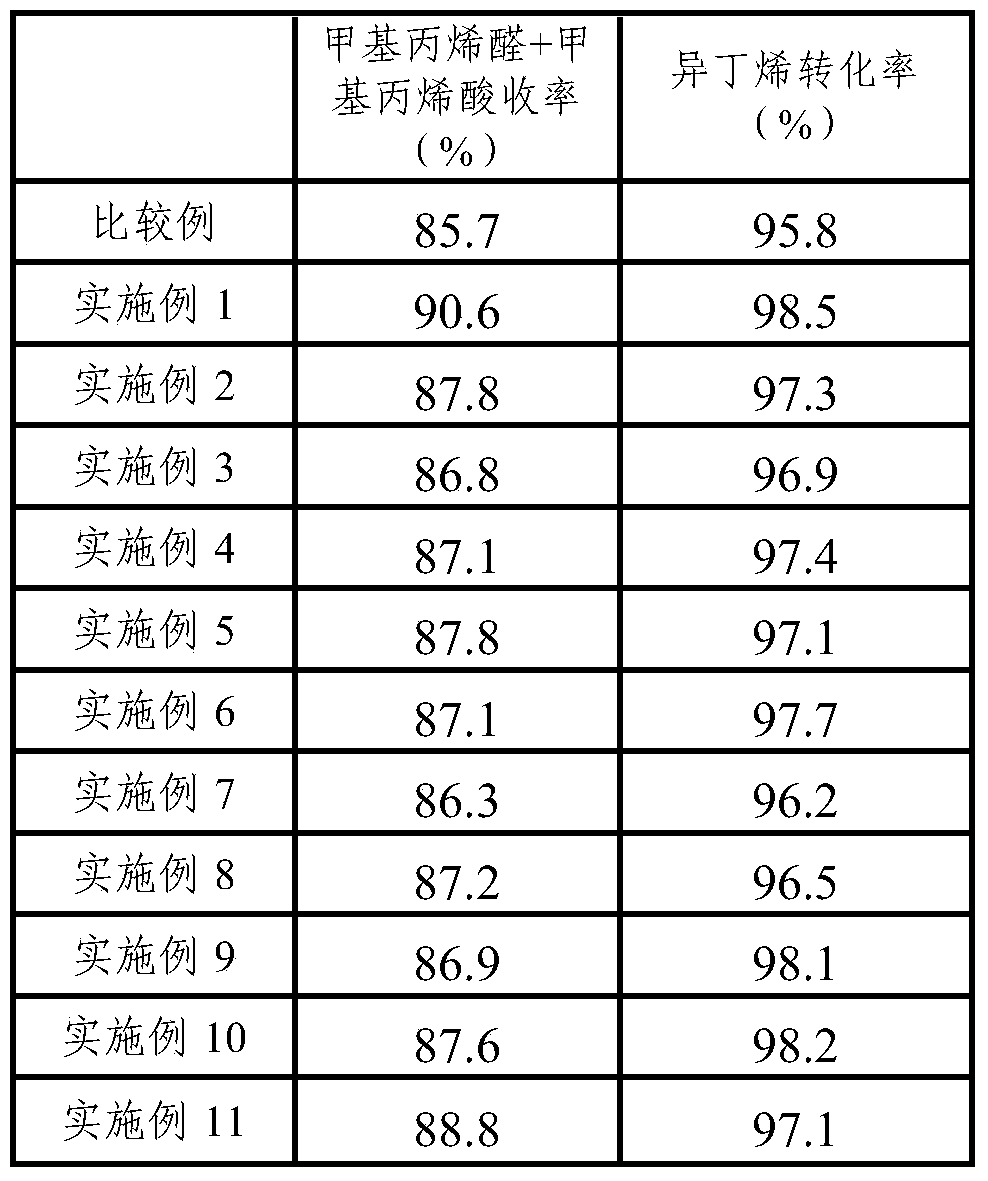

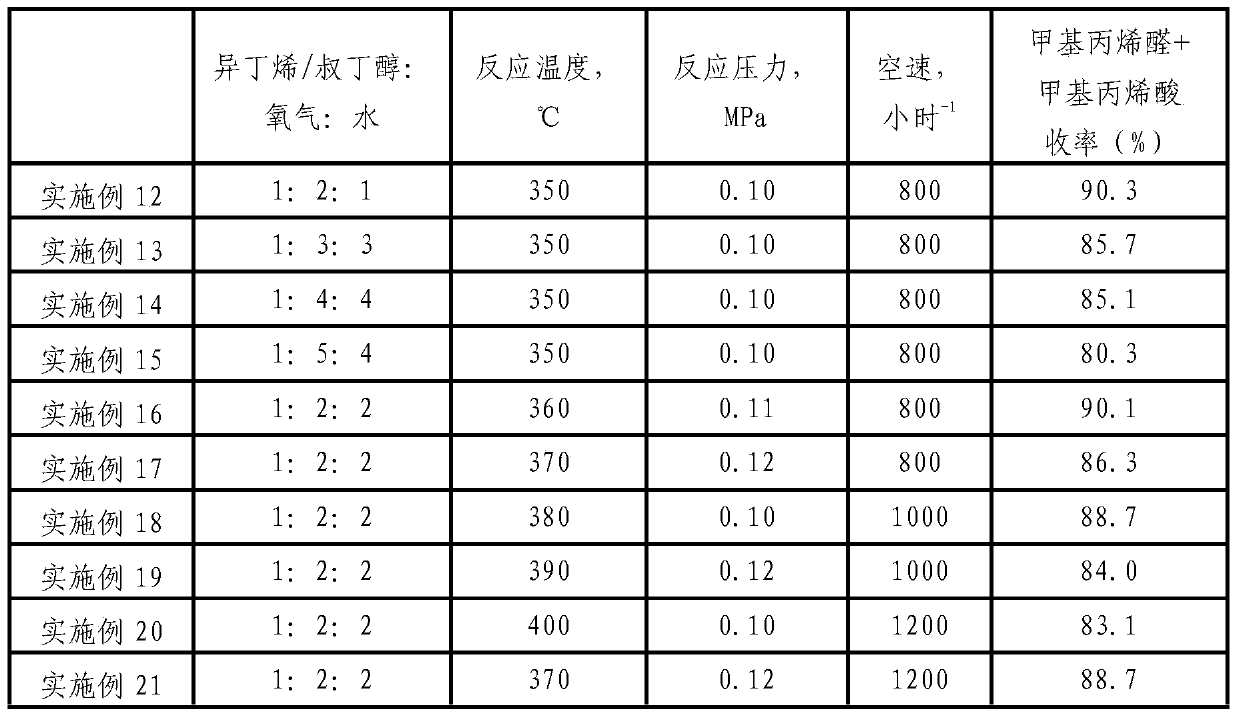

Examples

Embodiment 1

[0033] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of warm water at 70°C, stirred to dissolve it completely, and 89.4 grams of 40w% silica sol and 35.8 grams of 20w% aluminum sol were added to make material I.

[0034] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of hot water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 6.1 g Ce(NO 3 ) 3 ·6H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.2 g CsOH and 19.1 g (NH 4 ) 6 h 5 [H 2 (WO 4 ) 6 ] stirring and dissolving to make material II.

[0035]Add material II to material II to form a catalyst slurry, and stir and age at 80°C for 2 hours, then dry and calcine at a high temperature to obtain a finished catalyst at a calcination temperature of 450°C. The catalyst composition and preparation conditions are listed in Table 1. The molar ratio of isobutene or tert-butanol to oxygen is 1:2; the reaction temperature is 350°C; the reaction pressure is 0.1M...

Embodiment 2

[0037] 100 g (NH 4 ) 6 Mo 7 o 24 4H 2 O was added to 100 grams of warm water at 70°C, stirred to dissolve it completely, and 78.9 grams of 40w% silica sol and 47.7 grams of 20w% aluminum sol were added to make material I.

[0038] 38.5 g Fe(NO 3 ) 3 9H 2 O was added to 20 grams of hot water at 70°C, stirred and dissolved, and then 34.3 grams of Bi(NO 3 ) 3 ·5H 2 O, 41.2 g Co(NO 3 ) 2 ·6H 2 O, 6.1 g Ce(NO 3 ) 3 ·6H 2 O, 0.7 g Zn(NO 3 ) 2 ·6H 2 O, 0.5 g CH 3 COOCs and 8.24 g NH 4 VO 3 After stirring and dissolving, material II was produced.

[0039] Add material II to material I to form a catalyst slurry, and stir and age at 80°C for 2 hours, then dry and calcine at a high temperature to obtain a finished catalyst at a calcination temperature of 450°C. The catalyst composition and preparation conditions are listed in Table 1. The molar ratio of isobutene or tert-butanol to oxygen is 1:2; the reaction temperature is 350°C; the reaction pressure is 0.1MPa; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com