Application of fusion protein in cosmetics

A technology of fusion protein and cosmetics, applied in the application field of fusion protein in cosmetics, can solve the problem of no transdermal enhancement peptide, etc., achieve good biological activity and skin absorption rate, and maintain the effect of biological activity and skin absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

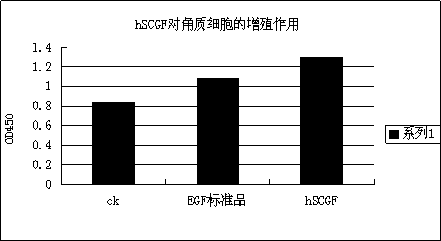

[0065] Obtaining TD1-hSCGF Fusion Protein

[0066]The fusion protein is prepared by the following method: extracting total RNA from the foreskin tissue of healthy newborns or circumcised children, designing PCR primer F1 according to the full-length human hSCGF gene sequence (GenBankAccessionNO.BC005810.2), F2; F1: GAGTCCAGCTTAATGC, F2: AAGACACTAACAAGGAGGAG, RT-PCR amplified hSCGF cDNA, covalently linked TD1 (transdermal peptide) to the N-terminus of hSCGF, and obtained the TD1-hSCGF fusion gene; cloned it into the prokaryotic expression plasmid pET -22b (+), construct the expression vector pET-22b-TD1-hSCGF, transform the expression plasmid into E.coliRosetta (DE3), and pass the TD1-hSCGF fusion protein through Ni 2 + ChelatingSegparoseFastFlow purification to obtain fusion protein.

Embodiment 2

[0068] An active stock solution containing a fusion protein, by weight percentage, comprising the following components:

[0069]

[0070] Production Process:

[0071] 1. Heat phase A to 85°C and homogenize for 2-3 minutes to dissolve completely. Add phase B to A, stir and keep warm for 20 minutes and then start to cool down; 2. Cool down to about 65°C and add phase C, stir well and then add phase D; 3, 40 At about ℃, add E to pass the plate and discharge it.

Embodiment 3

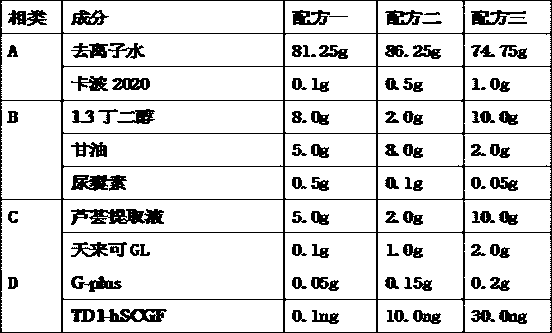

[0073] A kind of repair network peptide film containing fusion protein, by weight percentage, comprises the following components:

[0074]

[0075] Production Process:

[0076] 1. Heat phase A to 85°C and homogenize for 2-5 minutes to completely dissolve, add phase B to A and stir to dissolve, keep warm for 30 minutes and start to cool down; 2. Cool down to about 55°C and add phase C; 3. Lower the temperature to about 40°C and add D relative plate qualified discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com