Application of Composite Solution of γ-Cyclodextrin and Rare Earth Dy Complex in Microcontact Printing

A technology of micro-contact printing and compound solution, which is applied in the field of modern electronics, can solve the problems of unreported application and achieve the effect of easy-to-obtain raw materials and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The application of γ-cyclodextrin and rare earth Dy complex solution in microcontact printing, including:

[0029] Step 1, carboxylation of the substrate, soak the polyethylene substrate in 45% isopropanol aqueous solution for 30 minutes, then soak it in 2mol / L sulfuric acid at 55°C for 15 minutes, then wash it with water, and dry it in vacuum at 60°C to obtain carboxylated polyethylene base.

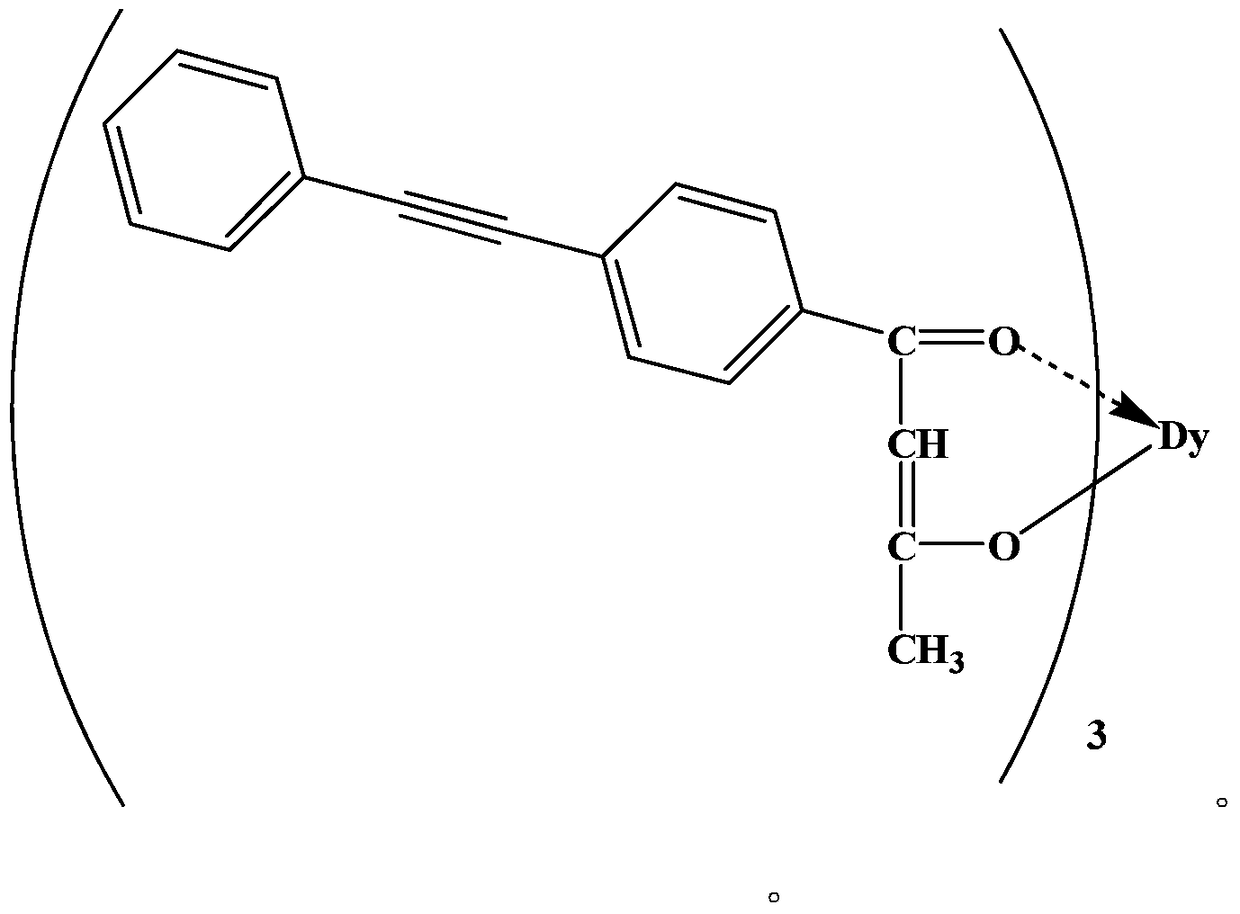

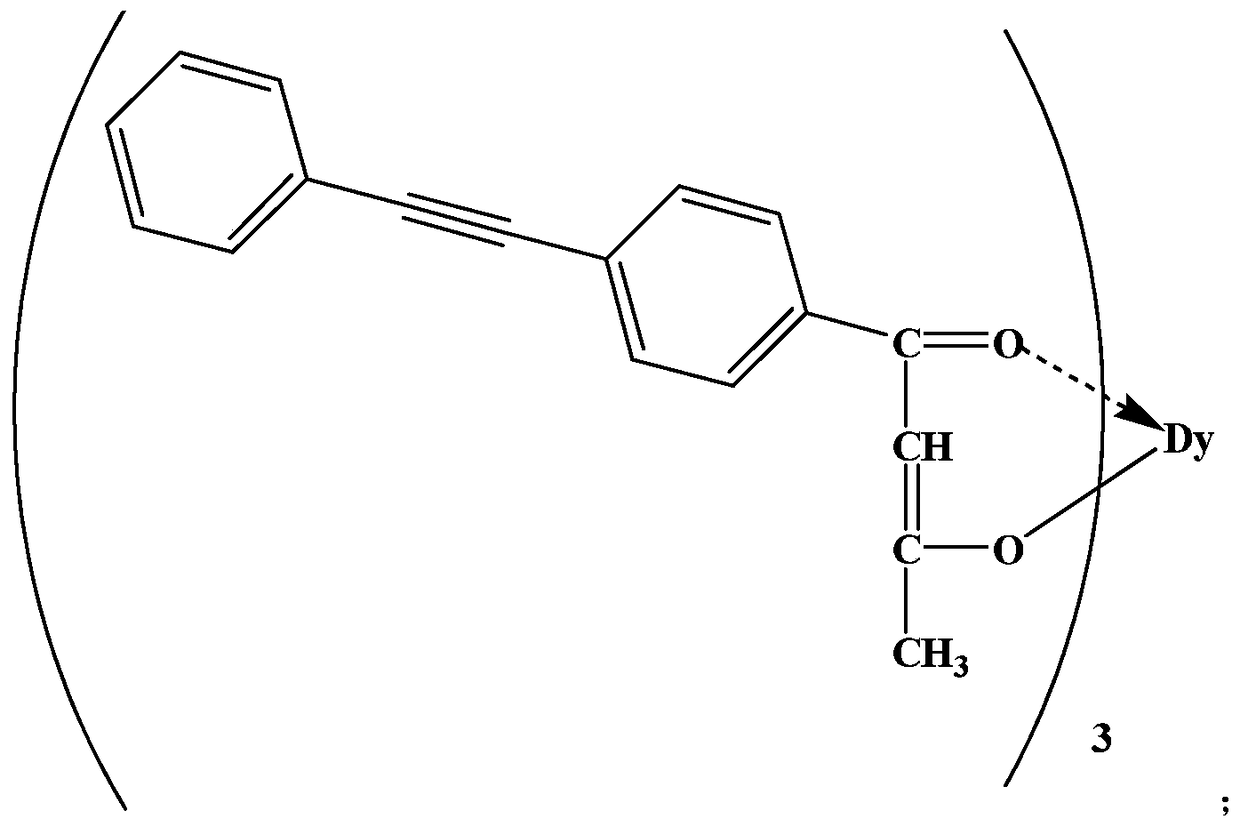

[0030] Step 2, preparing a complex solution of γ-cyclodextrin and rare earth Dy complex, dissolving γ-cyclodextrin in water to obtain an aqueous solution of γ-cyclodextrin with a concentration of 3g / L, adding 0.8g of the rare earth Dy complex was ultrasonically applied at 20kHz for 30min to obtain a uniformly dispersed composite solution of γ-cyclodextrin and the rare earth Dy complex.

[0031] Step 3, microcontact printing, soak the PDMS stamp in the complex solution of γ-cyclodextrin and rare earth Dy complex for 30s, take it out and put it in N 2 Dry in the air flow for 30s,...

Embodiment 2

[0034] The application of γ-cyclodextrin and rare earth Dy complex solution in microcontact printing, including:

[0035] Step 1, carboxylation of the substrate, soaking the polyethylene substrate in 50% isopropanol aqueous solution for 50 minutes, then soaking in 2.5mol / L sulfuric acid at 55-65°C for 20 minutes, then washing with water, and drying in vacuum at 60°C to obtain carboxyl groups Polyethylene base.

[0036] Step 2, preparing a complex solution of γ-cyclodextrin and rare earth Dy complex, dissolving γ-cyclodextrin in water to obtain an aqueous solution of γ-cyclodextrin with a concentration of 5g / L, and adding 0.8g of the rare earth Dy complex was ultrasonicated at 20kHz for 50min to obtain a uniformly dispersed composite solution of γ-cyclodextrin and the rare earth Dy complex.

[0037] Step 3, microcontact printing, soak the PDMS stamp in the complex solution of γ-cyclodextrin and rare earth Dy complex for 35s, take it out and put it in N 2 Dry in the air flow f...

Embodiment 3

[0040] The application of γ-cyclodextrin and rare earth Dy complex solution in microcontact printing, including:

[0041] Step 1, substrate carboxylation, soak the polyethylene substrate in 55% isopropanol aqueous solution for 60 minutes, then soak it in 3mol / L sulfuric acid at 55-65°C for 20 minutes, then wash it with water, and dry it in vacuum at 65°C to obtain carboxylation Polyethylene base.

[0042] Step 2, preparing a composite solution of γ-cyclodextrin and rare earth Dy complex, dissolving γ-cyclodextrin in water to obtain an aqueous solution of γ-cyclodextrin with a concentration of 6 g / L, and adding 0.8g of the rare earth Dy complex was ultrasonicated at 20kHz for 60min to obtain a uniformly dispersed composite solution of γ-cyclodextrin and the rare earth Dy complex.

[0043] Step 3, microcontact printing, soak the PDMS stamp in the complex solution of γ-cyclodextrin and rare earth Dy complex for 40s, take it out and put it in N 2 Dry in the air flow for 60s, cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com