In-situ-leaching uranium-mining drilling well-cementing slurry

A technology for in-situ leaching uranium mining and cementing, which is applied to drilling compositions, chemical instruments and methods, etc., can solve problems such as casing damage and unfavorable environmental protection, and achieves low pressure, mature cementing process, and reduced treatment. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

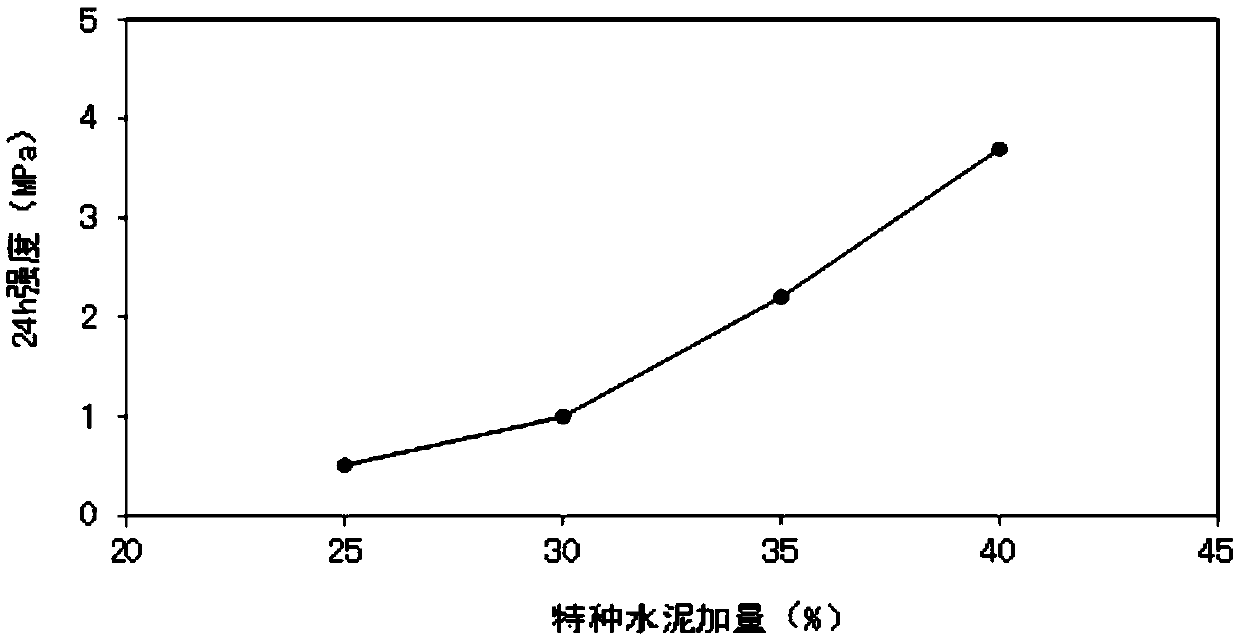

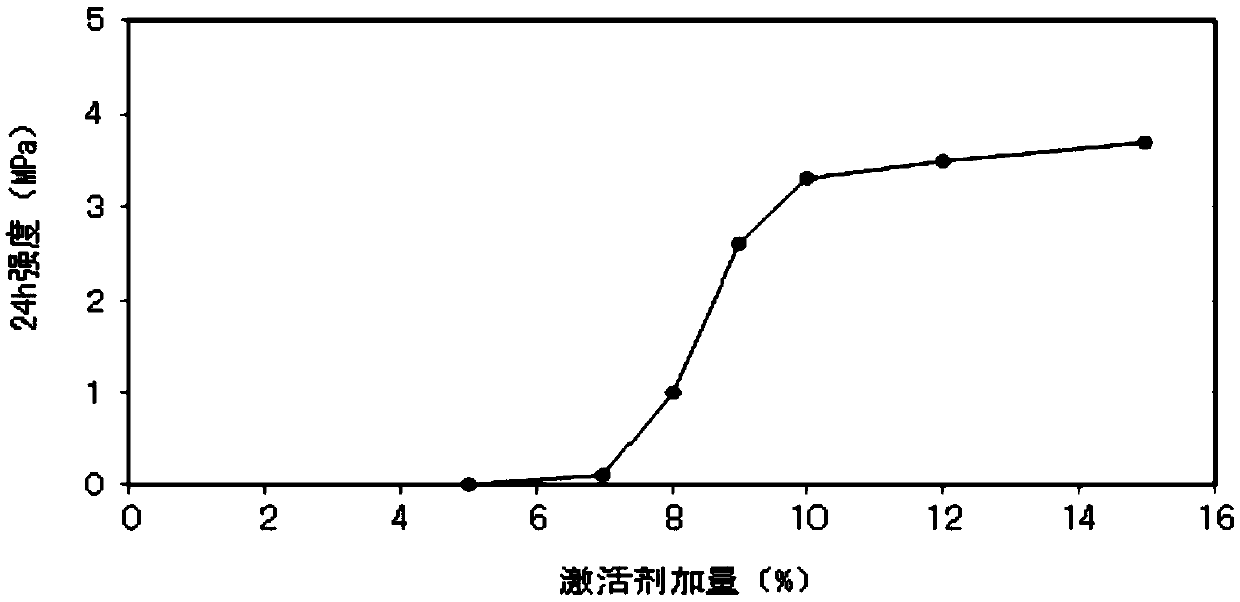

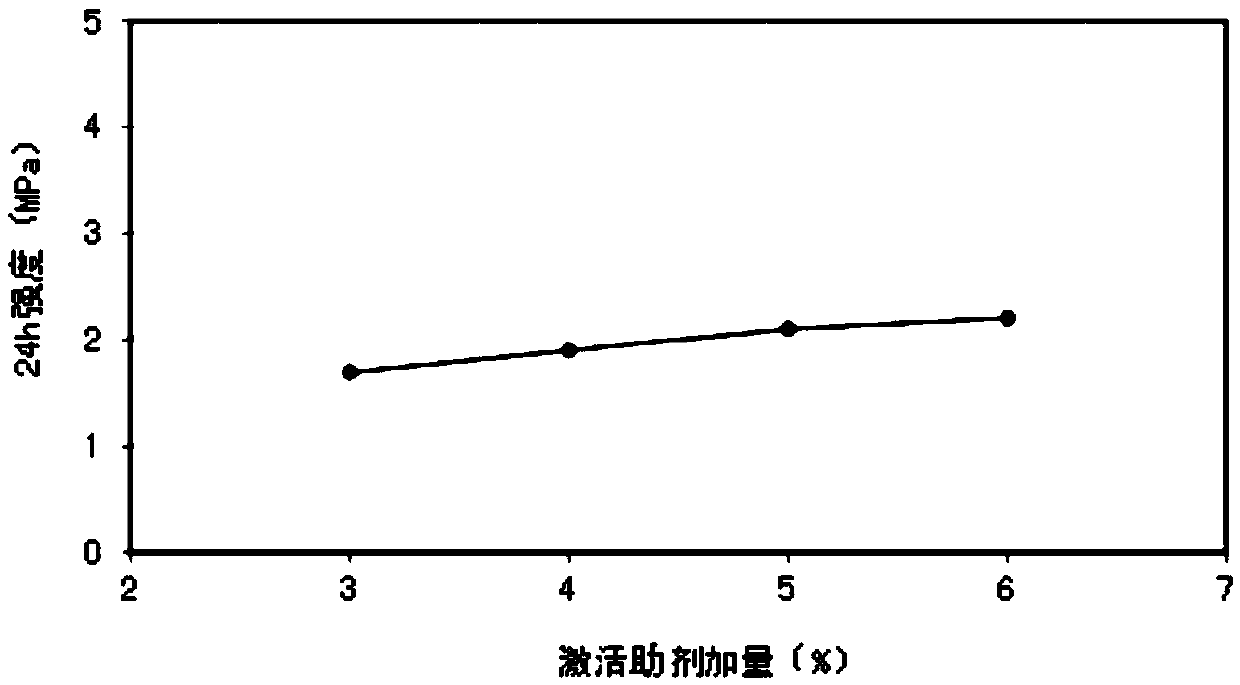

[0017] A drilling cementing slurry for uranium mining by in-situ leaching, comprising the following components:

[0018]

[0019]

[0020] Wherein, the percentage is the percentage of each admixture to the weight of the waste mud.

[0021] 1. Waste mud refers to the mud that is returned from the hole during the drilling construction process and is no longer used. It contains a certain proportion of bentonite, fine sand, water, etc., has good suspension and fluidity, and has a strong Toughness, plasticity and viscosity, its properties should be in the following ranges:

[0022] Density: 1.05~1.25g / cm 3 , Viscosity: 25 ~ 45s, sand content: 2.5 ~ 4% (volume ratio).

[0023] 2. Curing agent (slag): Slag is the waste residue produced in the iron-making process. After rapid water quenching at high temperature, a glassy granular hydraulic substance is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com