Electrostatic spinning machine

An electrospinning machine and spinning solution technology, applied in the field of electrospinning machines, can solve problems such as uneven fiber thickness, achieve the effects of reducing anisotropy, improving the uniformity of fiber thickness and fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

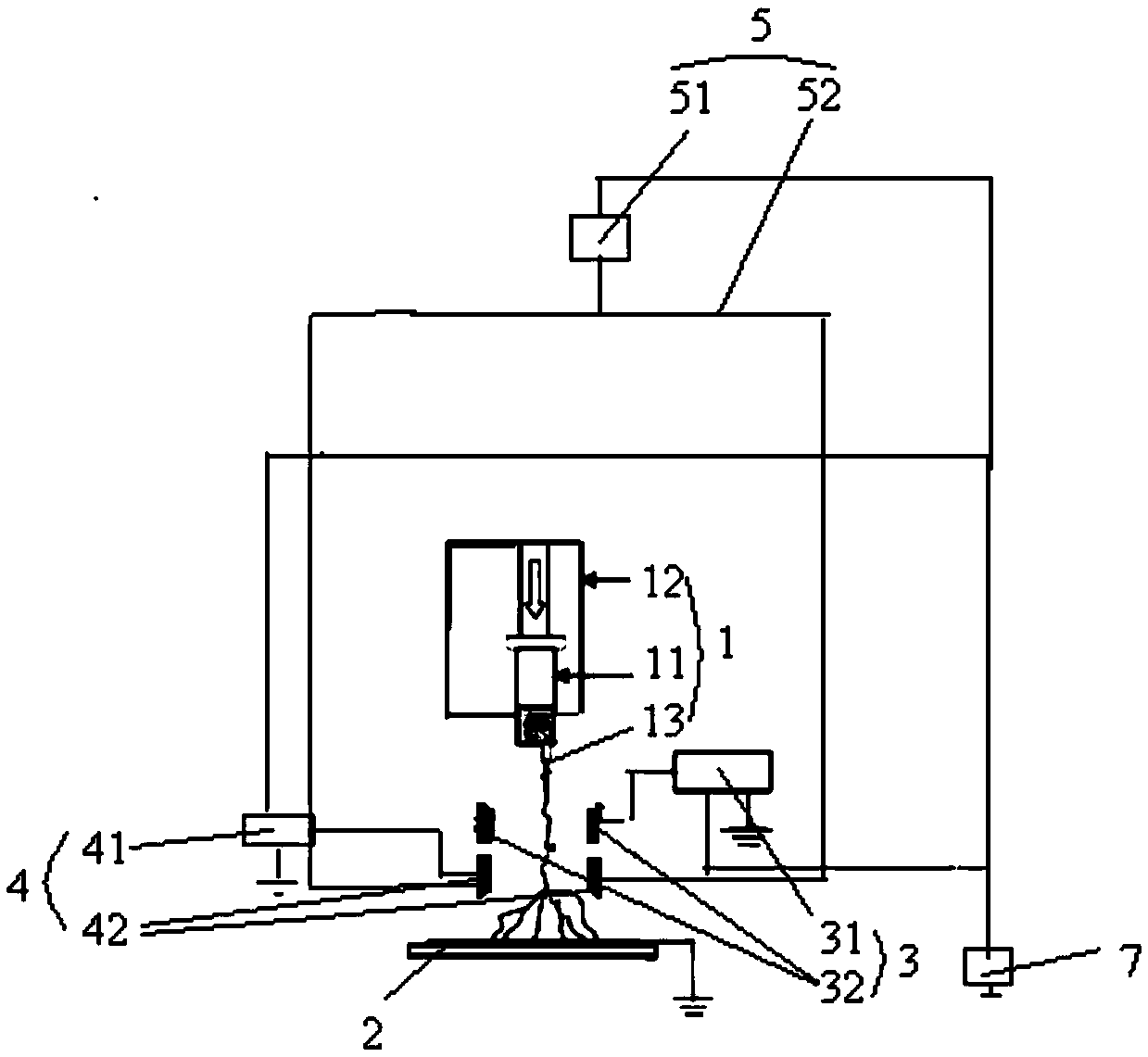

[0030] This embodiment provides an electrospinning machine such as figure 1 As shown, it includes: a spinning solution injection device 1; a fiber receiving device 2, which is arranged below the spinning solution injection device 1; the electrospinning machine also includes: an electric field generating device 3, including two The provided electrode plates 31 are distributed on both sides of the central axis between the spinning solution injection device 1 and the fiber receiving device 2; the magnetic field generating device 4 includes two magnetic pole plates 41 arranged vertically , distributed on both sides of the central axis; the first rotating device 5 is used to drive the magnetic pole plate 41 to rotate along the central axis.

[0031] In the electrospinning machine provided in this embodiment, by adding a magnetic field generating device and a first rotating device, the direction of the magnetic field is continuously changed around the central axis, thereby reducing ...

Embodiment 2

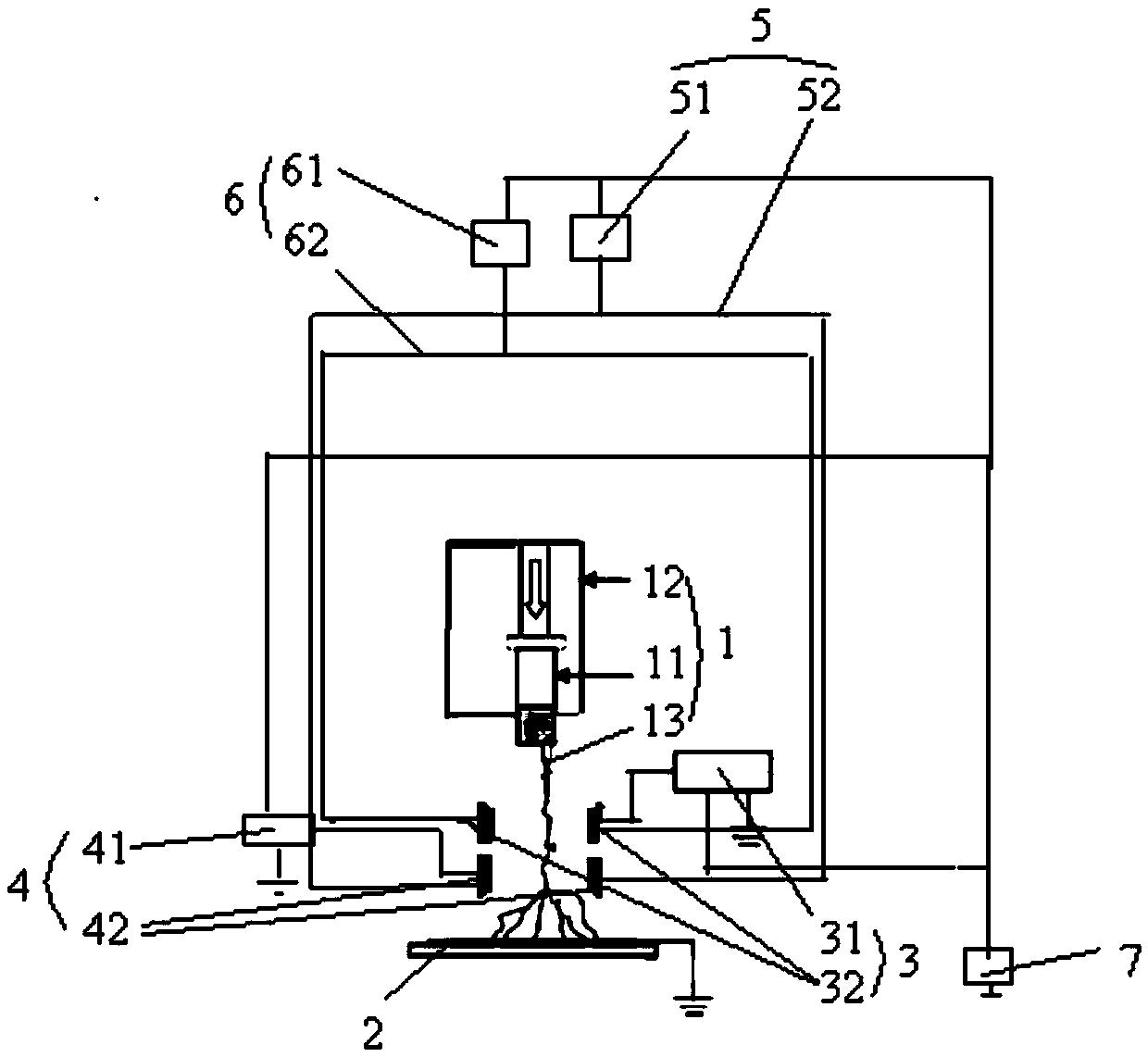

[0048] This embodiment provides an electrospinning machine, such as figure 2 As shown, it includes: a spinning solution injection device 1; a fiber receiving device 2, which is arranged below the spinning solution injection device 1; the electrospinning machine also includes: an electric field generating device 3, including two The provided electrode plates 31 are distributed on both sides of the central axis between the spinning solution injection device 1 and the fiber receiving device 2; the magnetic field generating device 4 includes two magnetic pole plates 41 arranged vertically , distributed on both sides of the central axis; the first rotating device 5 is used to drive the magnetic pole plate 41 to rotate along the central axis; the second rotating device 6 is used to drive the electrode plate 31 along the The central axis performs rotational movement.

[0049] In the electrospinning machine provided in this embodiment, by adding a second rotating device, the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com