A kind of preparation method of orientation alignment barium titanate nanofiber

A technology for arranging barium titanate and nanofibers, applied in fiber processing, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of small aspect ratio of nanowires, uncontrollable mutual arrangement of nanowires, etc., and achieve industrialization potential Huge, good crystallinity, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] First, 2.55g of barium acetate was added to 8.0g of acetic acid, stirred at 25°C for 1h on a magnetic stirrer to fully dissolve, then 3.40g of tetrabutyl titanate was added, and stirred for 1h to form a precursor solution. Add 1.8 g of polyvinylpyrrolidone to 8 g of ethanol, and stir on a magnetic stirrer at 25° C. for 12 hours to form a homogeneous polymer solution. The above two solutions were mixed and stirred on a magnetic stirrer for 1 h to obtain a spinning solution.

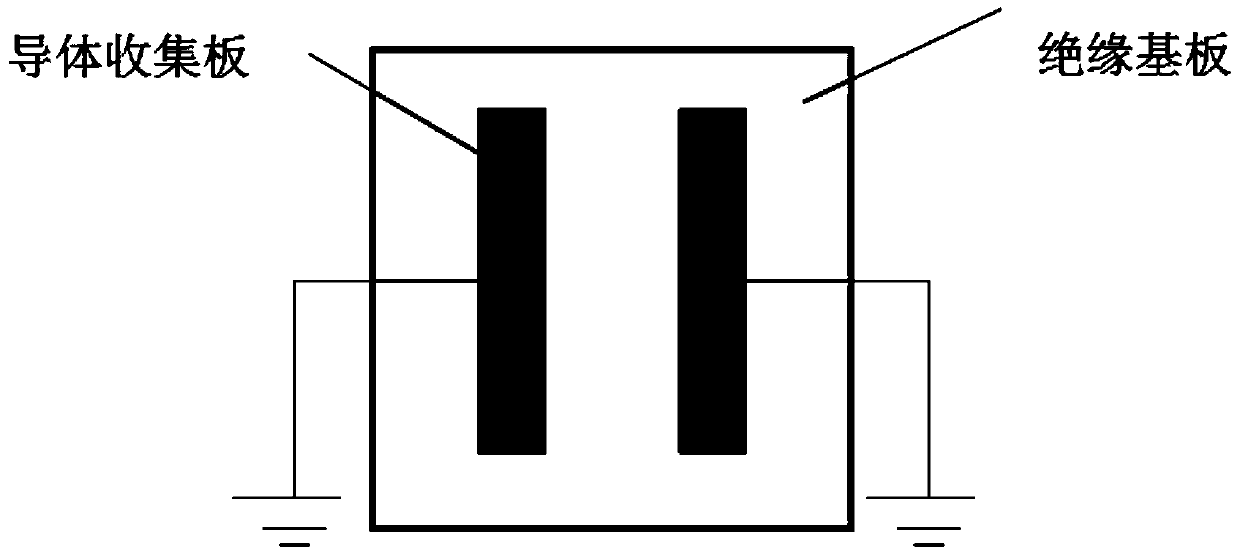

[0033] Use a micro-injection pump to inject the electrospinning solution from the syringe for electrospinning. The anode of the high-voltage generator is connected to the end of the micro-injector, and the cathode is connected to the collection device, wherein: the collection device consists of an insulating substrate It is composed of two conductor collecting plates arranged longitudinally and parallelly on the insulating substrate. The conductor collecting plates are grounded. The distance between...

Embodiment 2

[0036] First, 1.275g of barium acetate was added to 8.0g of acetic acid, stirred at 25°C for 1h on a magnetic stirrer to fully dissolve, then 1.70g of tetrabutyl titanate was added, and stirred for 1h to form a precursor solution. Add 1.8 g of polyvinylpyrrolidone to 12 g of ethanol, and stir on a magnetic stirrer at 25° C. for 12 hours to form a homogeneous polymer solution. The above two solutions were mixed and stirred on a magnetic stirrer for 1 h to obtain a spinning solution.

[0037] Use a micro-injection pump to inject the electrospinning solution from the syringe for electrospinning. The anode of the high-voltage generator is connected to the end of the micro-injector, and the cathode is connected to the collection device, wherein: the collection device consists of an insulating substrate It is composed of a conductor collecting plate arranged longitudinally and parallelly on the insulating substrate, the conductor collecting plate is grounded, the distance between tw...

Embodiment 3

[0040] First, 1.275g of barium acetate was added to 10g of acetic acid, stirred at 25°C for 1h on a magnetic stirrer to fully dissolve, then 1.70g of tetrabutyl titanate was added, and stirred for 1h to form a precursor solution. Add 2 g of polyvinylpyrrolidone to 10 g of ethanol, and stir on a magnetic stirrer at 25° C. for 12 hours to form a homogeneous polymer solution. The above two solutions were mixed and stirred on a magnetic stirrer for 1 h to obtain a spinning solution.

[0041] Use a micro-injection pump to inject the electrospinning solution from the syringe for electrospinning. The anode of the high-voltage generator is connected to the end of the micro-injector, and the cathode is connected to the collection device, wherein: the collection device consists of an insulating substrate It is composed of a conductor collecting plate arranged longitudinally and parallelly on the insulating substrate. The conductor collecting plate is grounded. The distance between two c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com