Method for puffing refined silk

A silk bulking agent and silk technology, applied in the direction of improved hand fiber, textiles and papermaking, fiber treatment, etc., can solve the problems that the effect is not very good, can not meet the actual production of the factory, and achieve low production cost, which is conducive to popularization and application , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

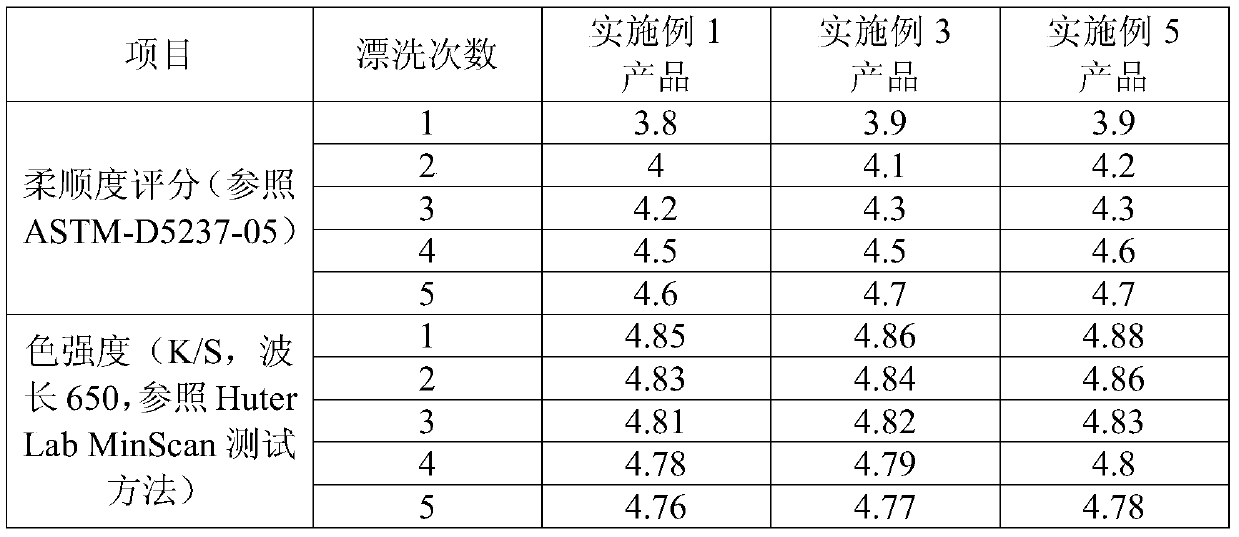

Examples

Embodiment 1

[0030] A method for expanding silk after refining, comprising the following steps:

[0031] S1, the first rinsing: put the refined silk in deionized water at 35°C for the first rinsing, and dehydrate after the first rinsing to obtain dehydrated silk;

[0032] S2. Infiltration: Put the dehydrated silk prepared in step S1 into a silk swelling agent solution with a mass ratio of silk swelling agent and deionized water of 1:100, at a vacuum degree of 0.91Mpa, and at a low temperature of 20°C Vacuum infiltration treatment dehydrated silk for 15 minutes, repeat the low-temperature vacuum infiltration treatment of step S2 twice, and place the silk for 16 hours. The silk bulking agent, in parts by weight, includes the following raw materials: 525 parts of relaxing agent, 48.4 parts of softening agent Parts, the release agent includes the following raw materials: Na 2 SiO 3 25 parts, 500 parts of deionized water; the softening agent includes the following raw materials: 6 parts of es...

Embodiment 2

[0043] A method for expanding silk after refining, comprising the following steps:

[0044] S1, the first rinsing: put the refined silk in deionized water at 65°C for the first rinsing, and dehydrate after the first rinsing to obtain dehydrated silk;

[0045] S2. Infiltration: Put the dehydrated silk prepared in step S1 into a silk swelling agent solution with a mass ratio of silk swelling agent and deionized water of 1:200, at a vacuum degree of 0.95Mpa and a temperature of 25°C. Vacuum infiltration treatment dehydrated silk for 5 minutes, repeat the low-temperature vacuum infiltration treatment of step S2 3 times, and place the silk for 8 hours. The silk bulking agent, in parts by weight, includes the following raw materials: 1240 parts of relaxing agent, 97.4 parts of softening agent Parts, the release agent includes the following raw materials: Na 2 SiO 3 40 parts, 1200 parts of deionized water; the softening agent includes the following raw materials: 12 parts of ester ...

Embodiment 3

[0056] A method for expanding silk after refining, comprising the following steps:

[0057] S1, the first rinsing: put the refined silk in deionized water at 50°C for the first rinsing, and dehydrate after the first rinsing to obtain dehydrated silk;

[0058] S2. Infiltration: Put the dehydrated silk prepared in step S1 into a silk swelling agent solution with a mass ratio of silk swelling agent and deionized water of 1:150, at a vacuum degree of 0.93Mpa and a temperature of 22°C. Vacuum infiltration treatment dehydrated silk for 10 minutes, repeat the low-temperature vacuum infiltration treatment of step S2 3 times, and place the silk for 12 hours. The silk bulking agent, in parts by weight, includes the following raw materials: relaxing agent 910 part, 73 parts of softening agent, described relaxing agent comprises following raw material: Na 2 SiO 3 60 parts, 850 parts of deionized water; the softening agent includes the following raw materials: 9 parts of ester group quat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com