Novel production technology of anti-counterfeiting safety line boards

A production process and security thread technology, applied in the production process field of new security thread security paper, can solve the problems of inaccurate security thread positioning, easy curling of paper, and difficulty in controlling the security thread production process, so as to achieve uniform window graphics and text, Solve the effect of easy curling and clear visual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

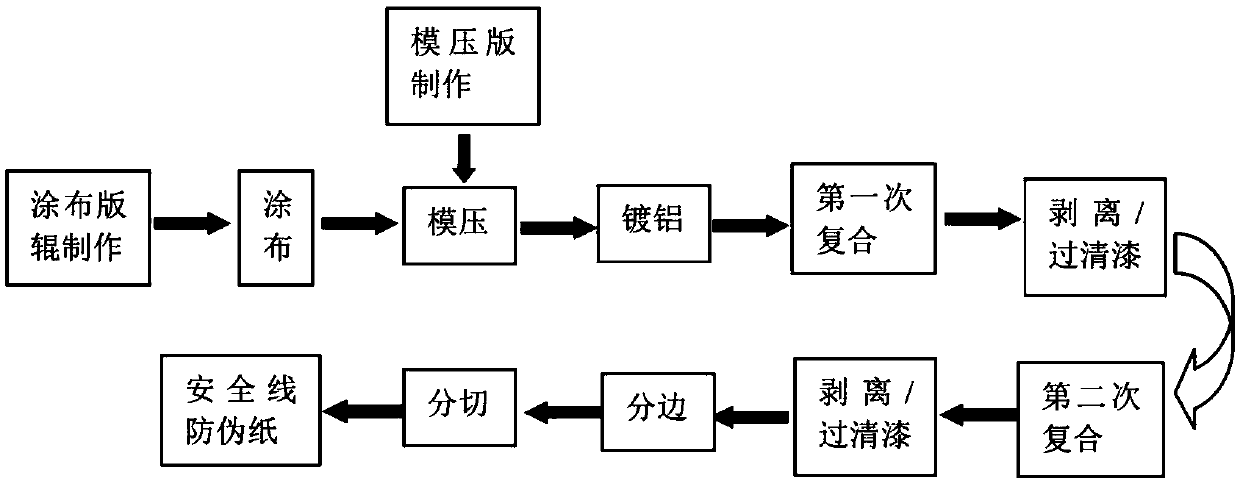

[0027] Such as figure 1 As shown, a production process of a novel security thread anti-counterfeiting paper includes the following main steps:

[0028] (1) Manufacture of coating rollers: the production of coating rollers is to form cells on the surface of the coating rollers by electric carving or laser engraving. The depth of the cells determines the coating amount of the thermoplastic coating. Thickness has a greater impact on the quality of subsequent thermoplastic molding. In order to avoid the phenomenon of incomplete information or plate sticking in the molding process, the depth of the coating roller cell in the present invention is 30-50μ;

[0029] (2) Coating: use a coating roller to coat a layer of thermoplastic paint on the plastic base film and dry it. The base film is preferably a PET transfer film; the thermoplastic paint can be diluted with a solvent, and the viscosity of the thermoplastic paint has a certain effect on the molding quality. The influence of las...

Embodiment 2

[0040] (1) Manufacture of coating rollers: the production of coating rollers is to form cells on the surface of the coating rollers by electric carving or laser engraving. The depth of the cells determines the coating amount of the thermoplastic coating. Thickness has a greater impact on the quality of subsequent thermoplastic molding. In order to avoid the phenomenon of incomplete information or plate sticking in the molding process, the depth of the coating roller cell in the present invention is 30-50μ;

[0041] (2) Coating: use a coating roller to coat a layer of thermoplastic paint on the plastic base film and dry it. The base film is preferably a PET transfer film; the thermoplastic paint can be diluted with a solvent, and the viscosity of the thermoplastic paint has a certain effect on the molding quality. The influence of laser coating in the present invention is that the viscosity of the 4# cup is 15-25 seconds. The coating speed is 80-120m / min, and the oven temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com