Bridge plate foundation instant construction technology

A technology for foundation and bridge deck, which is applied in the field of rapid construction of bridge deck foundation, which can solve the problems of land pollution and increase in the amount of construction works, and achieve the effects of increasing the speed, reducing the amount of construction works, and reducing underground pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings. However, the embodiments of the present invention are not limited thereto.

[0012] First, harden the floor where the bridge slab foundation is located, level and compact the site, soak the concrete floor evenly with concrete hardener, and complete the hardening of the floor after grinding, maintenance, and polishing.

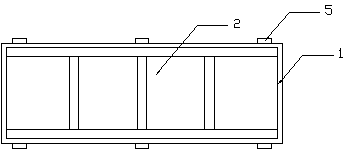

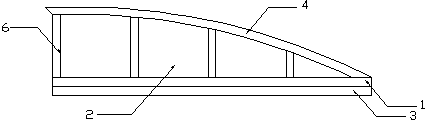

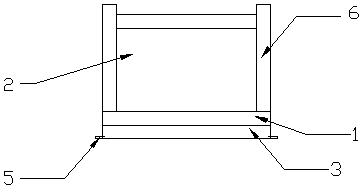

[0013] In the production workshop, according to the ratio of white lime and clay 3:7, the thickness is 600mm, and the embedded steel plate 5 is placed at the bottom to prefabricate the lime soil layer 3, and then continue to prefabricate the 600mm thick concrete layer 1 on this basis, and prefabricate on the concrete layer 1 During the process, the embedded steel plate 5 connected to the bridge pier 6 is added, the bridge pier 6 is connected to the embedded steel plate 5 in the concrete layer 1, and the lime soil layer 3, the concrete layer 1 and the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com