Ground connecting wall flexible impervious body construction method and structure thereof

A technology of connecting a wall and an anti-seepage body, which is applied in the field of underground engineering construction and civil engineering, can solve problems such as gaps and water leakage, and achieve the effect of solving leakage, preventing leakage and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

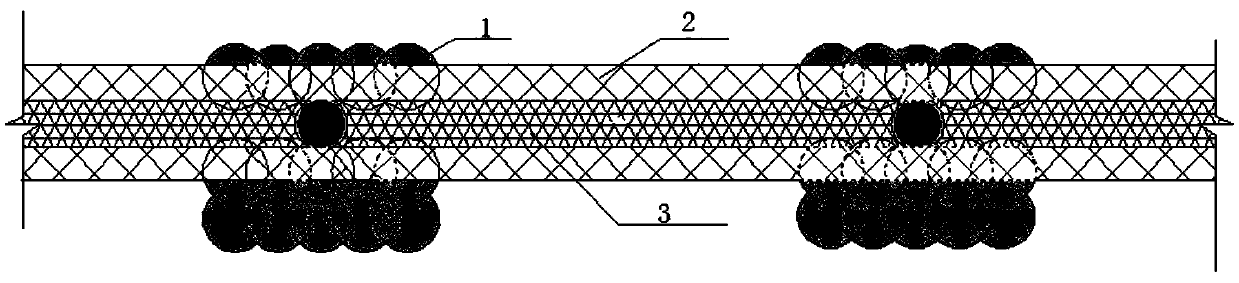

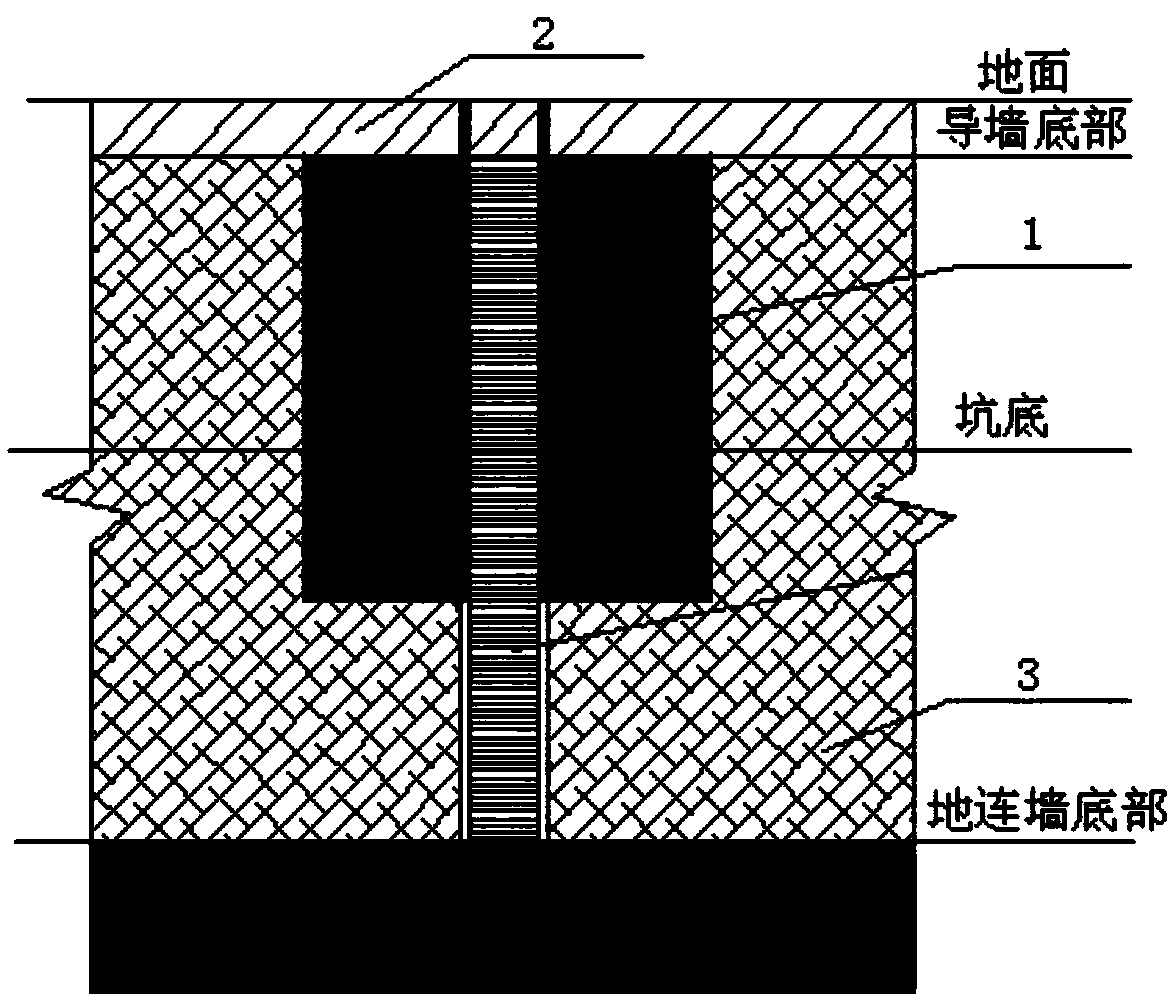

[0039] Measurement and setting out, on the site to be built, set out the line according to the design drawings, and determine the axis of the ground connection wall and the position of each groove section. According to the soil quality, set the construction parameters such as spray irrigation pressure and lifting speed, use the drilling rig to spray sodium-based bentonite into the soil, and mix it with the original soil evenly to form a composite soil pile. At the joint position of the ground connection wall, interlocking composite soil piles are applied along the thickness direction of the wall, and the interlocking between the two piles is 100-200mm to form a flexible composite soil anti-seepage body. The construction scope of the composite soil anti-seepage body: along the axis direction of the ground connection wall, the two sides of the joint extend 1m; along the wall thickness direction, there are 2 rows of piles outside the wall and 1 row of piles inside the wall; along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com