Composite vacuum glass with suspended film double hollow

A vacuum glass, double hollow technology, applied in the direction of parallel glass structure, window/door improvement, climate change adaptation, etc. The effect of reducing stress impact and improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

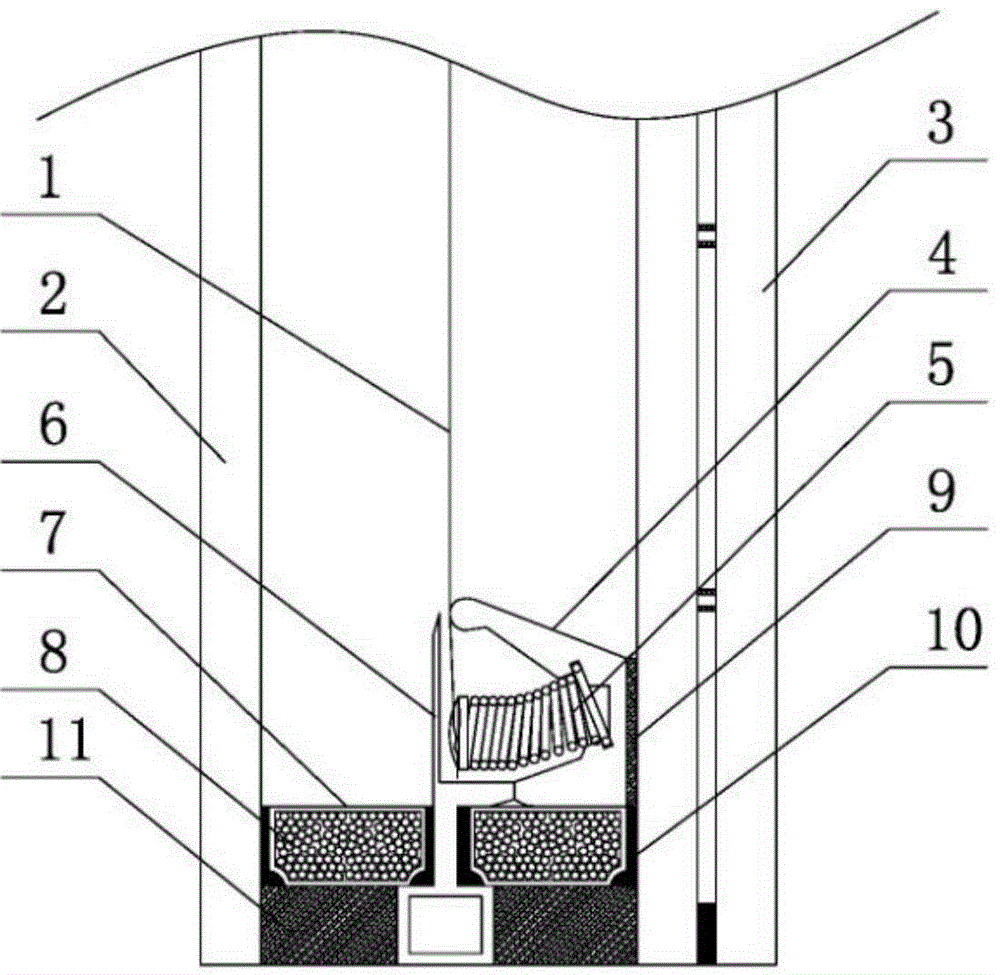

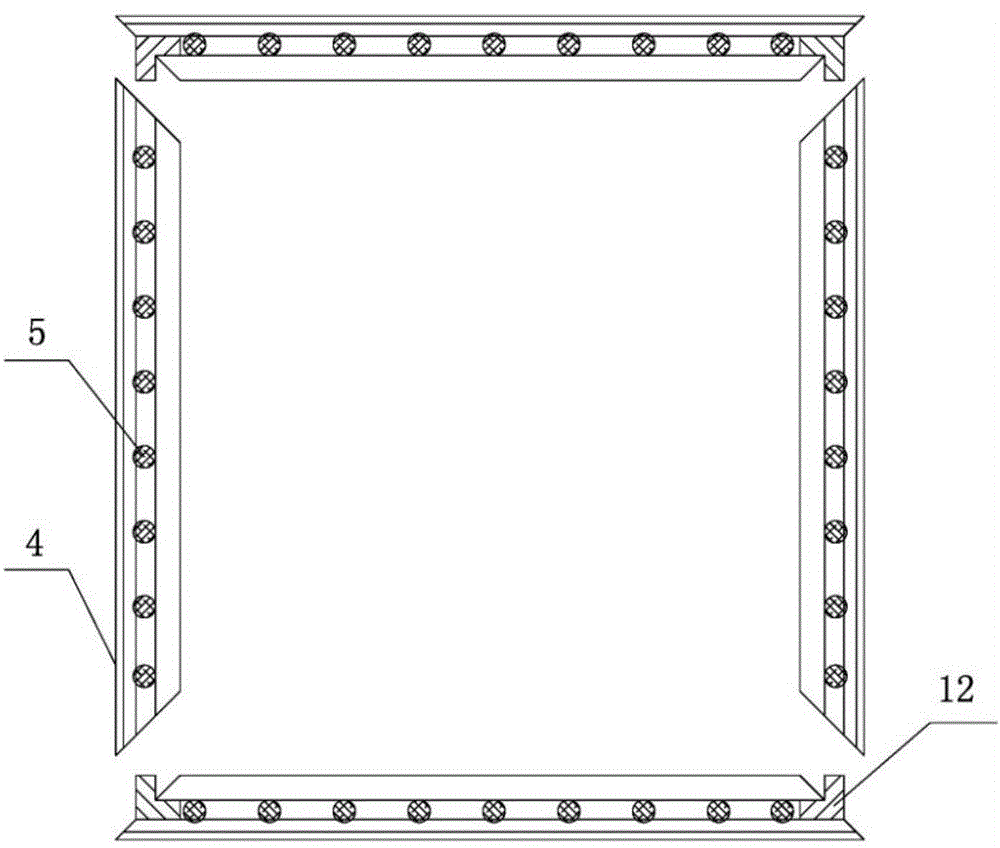

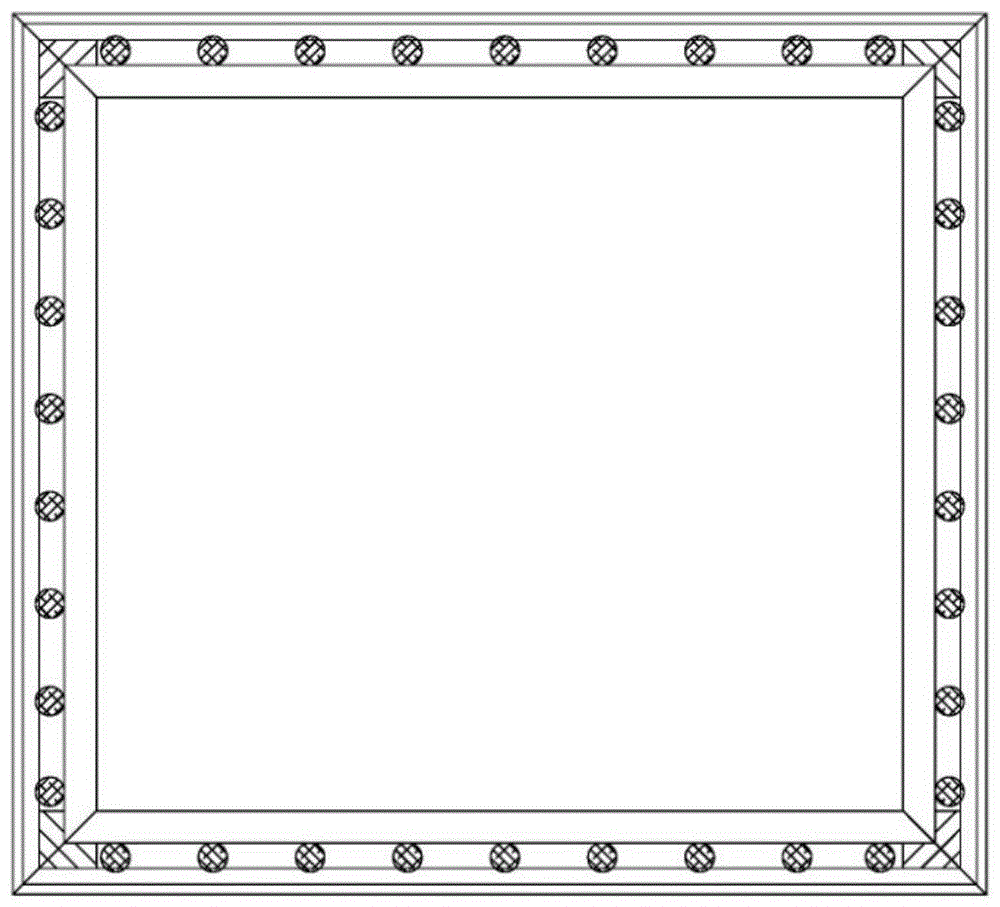

[0039] Such as figure 1 The composite vacuum glass with double-hollow suspension film shown includes outer glass 2, outer warm edge spacer frame 7.2, middle cover plate frame 6, optical plastic film 1, stretch film frame 4, and inner warm edge spacer frame 7.1 and vacuum glass3. The optical plastic film 1 is fixed on the inner side of the vacuum glass 3 by the stretch film frame 4, and is surrounded by a warm-side spacer frame (that is, an inner warm-side spacer frame 7.1) outside the cavity formed by the optical plastic film and the vacuum glass. The center cover frame 6 is installed on the inner warm edge spacer frame, and then the warm edge spacer frame of the same structure (that is, the outer warm edge spacer frame 7.2) is installed on the center cover plate frame and the outer glass 2, and finally the optical plastic film 1 separates the inner cavity formed by the outer glass 2 and the vacuum glass 3 into a buffer double hollow inner cavity for offsetting the stress im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com