Ball seat of ball injection activated sliding sleeve, manufacture method of ball seat and sliding sleeve

A ball seat and sliding sleeve technology, applied in the field of oil and natural gas exploration, can solve the problems of prolonging the fracturing construction time and bringing construction risks, etc., and achieve the effect of effective sealing and close contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

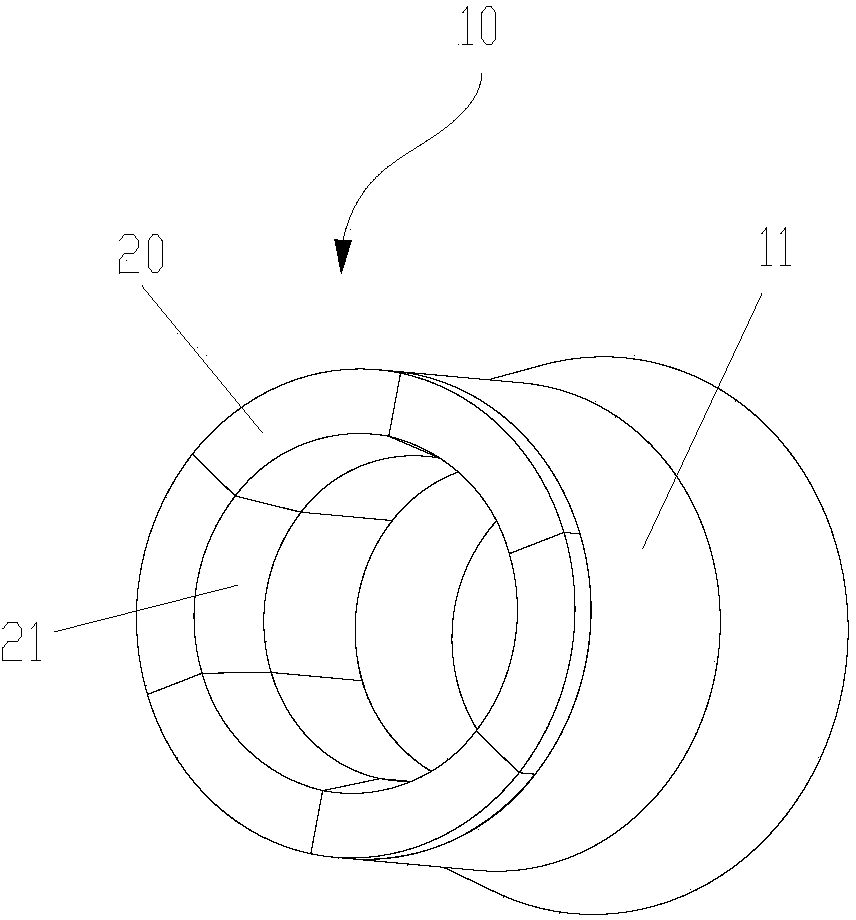

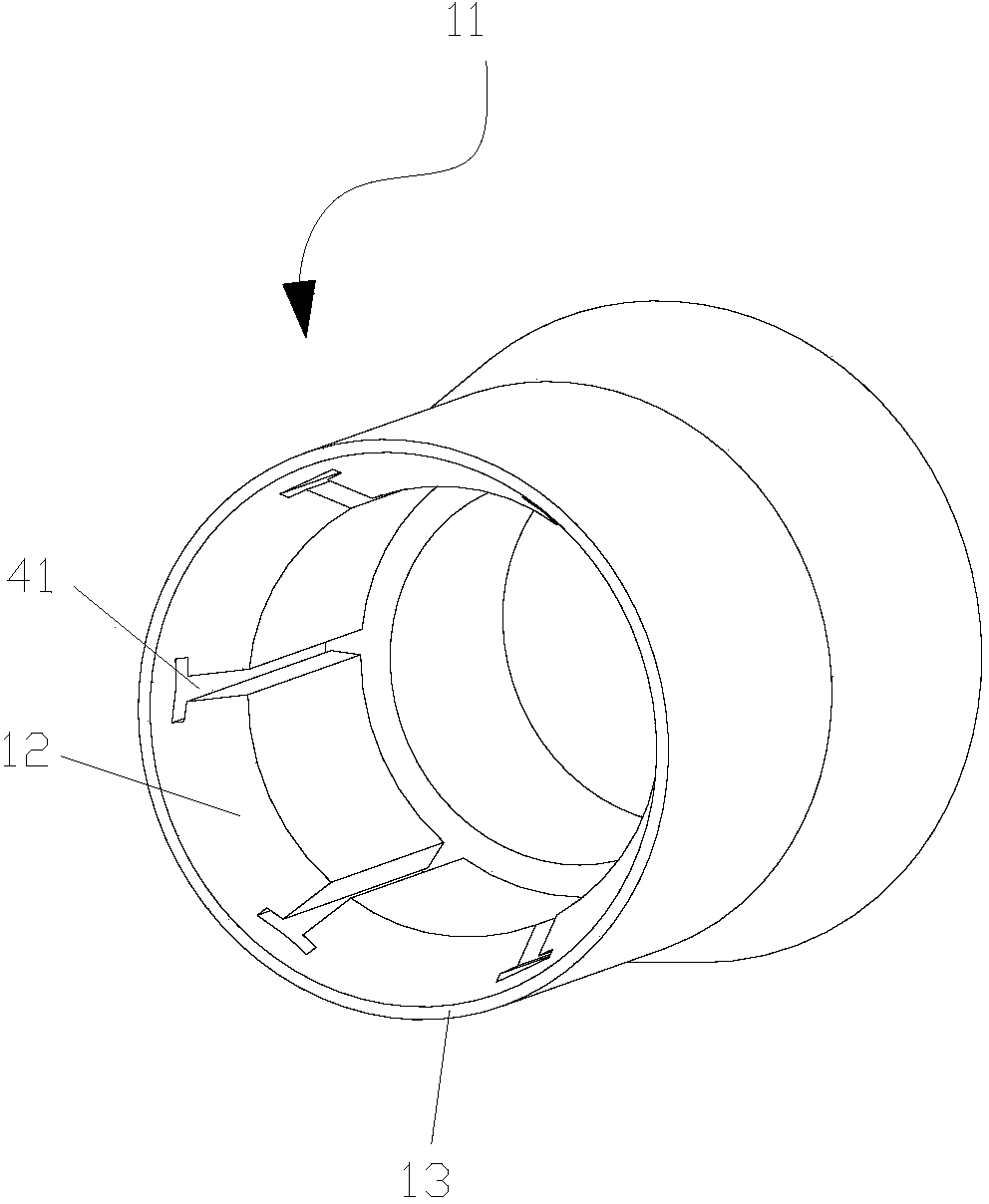

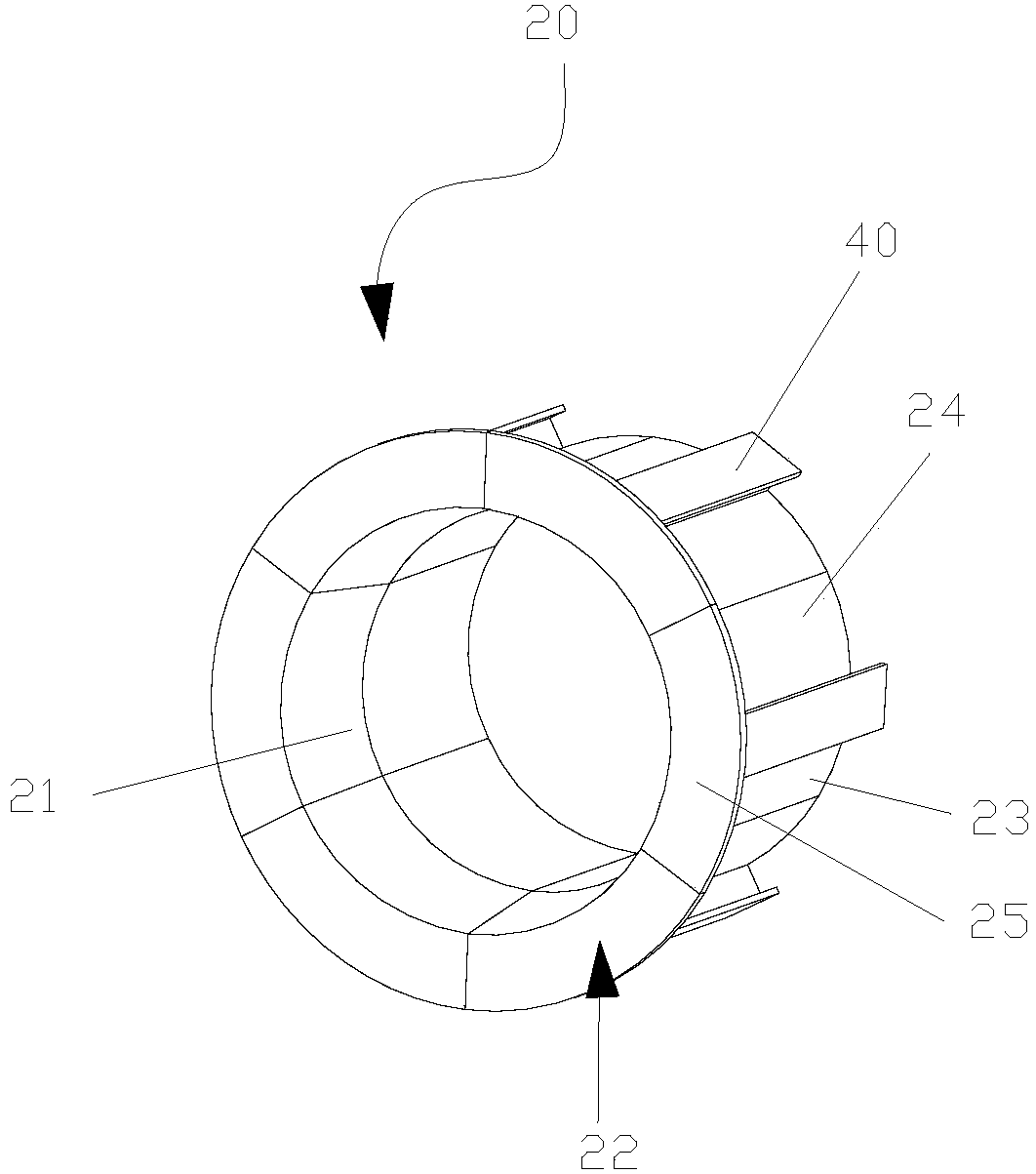

[0024] figure 1 A tee 10 (hereinafter referred to as tee 10 ) of a pitching open sleeve according to the present invention is shown in three-dimensional view. Such as figure 1 As shown, the ball seat 10 includes a cylindrical body 11 and a pressure bearing sleeve 20 installed in the cylindrical body 11 . The pressure sleeve 20 is used to accept the pressure holding ball (not shown) thrown into the well, and the cylindrical body 11 is used to connect with the sliding sleeve (not shown) to realize the installation of the ball seat 10 in the sliding sleeve. In one embodiment, a male thread can be provided on the outer surface of the cylindrical body 11 , and a female thread can be provided on a corresponding part of the sliding sleeve, thereby realizing the connection between the ball seat 10 and the sliding sleeve.

[0025] After the fracturing operation is completed, in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com