Method for quickly detecting total iron grades of hematite concentrates

A hematite and iron grade technology, applied in the direction of measuring devices, specific gravity measurement, instruments, etc., can solve problems such as unfavorable environmental protection, unfavorable health of laboratory personnel, and influence on production development, so as to reduce the hazards of laboratory personnel and the environment, significantly Economic and social benefits, accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The raw ore used in this embodiment is the raw ore of a hematite ore dressing plant, and the total iron grade is 29.45%.

[0035] Take 6 samples of raw hematite ore and put them into a mill for grinding. The grinding particle size is as follows: the first sample - 200 mesh accounts for 47.23%, the second sample - 200 mesh accounts for 55.18%, the third sample The ore sample - 200 mesh accounted for 62.37%, the fourth ore sample - 200 mesh accounted for 74.83%, the fifth ore sample - 200 mesh accounted for 88.24%, and the sixth ore sample - 200 mesh accounted for 97.36%. Weigh 3500g of each particle size, sort through the spiral chute twice, and then sample and test the obtained iron ore concentrate products after drying. .

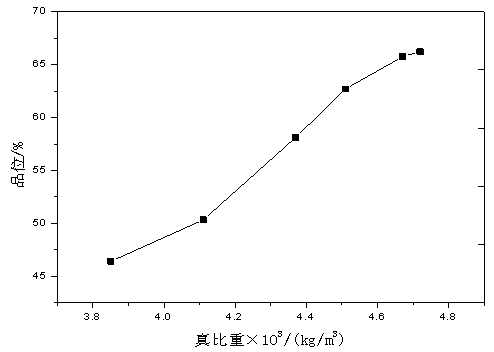

[0036] Using the pycnometer method to measure the true specific gravity of the obtained different iron ore concentrate products, they were 3.85×10 3 kg / m 3 , 4.12×10 3 kg / m 3 , 4.37×10 3 kg / m 3 , 4.51×10 3 kg / m 3 , 4.67×10 3 kg / m 3 , 4.73...

Embodiment 2

[0040] The raw ore used in this embodiment is the raw ore of a hematite ore dressing plant, and the total iron grade is 21.78%.

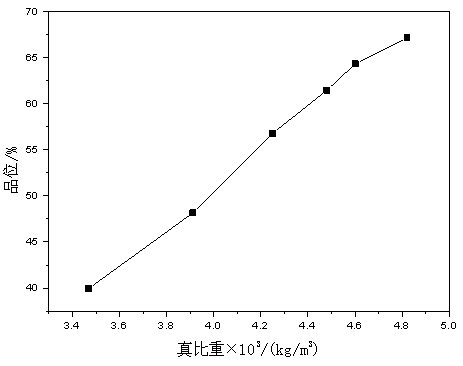

[0041]Take 6 samples of raw hematite ore and put them into a mill for grinding. The grinding particle size is as follows: the first ore sample -200 mesh accounts for 41.58%, the second ore sample -200 mesh accounts for 54.31%, the third The ore sample - 200 mesh accounted for 64.14%, the fourth ore sample - 200 mesh accounted for 72.36%, the fifth ore sample - 200 mesh accounted for 85.71%, and the sixth ore sample - 200 mesh accounted for 94.59%. Weigh 4000g of each particle size, sort through the spiral chute for 3 times, and then sample and test the obtained iron concentrate products after drying. The grades are 39.94%, 48.15%, 56.78%, 61.49%, 64.35%, 67.18% .

[0042] Use the pycnometer method to measure the true specific gravity of different iron ore concentrate products obtained, which are 3.47×10 3 kg / m 3 , 3.91×10 3 kg / m 3 , 4.25×10 3 ...

Embodiment 3

[0046] The raw ore used in this embodiment is the raw ore of a certain hematite ore dressing plant, and the total iron grade is 32.47%.

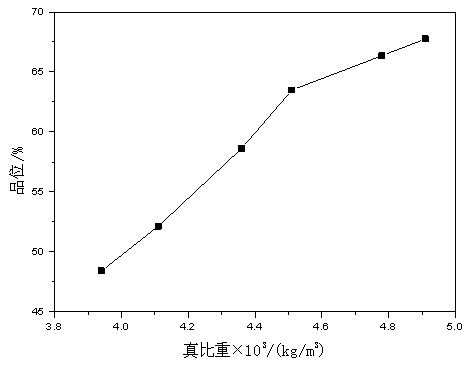

[0047] Take 6 samples of raw hematite ore and put them into a mill for grinding. The grinding particle size is as follows: the first ore sample -200 mesh accounts for 45.21%, the second ore sample -200 mesh accounts for 57.56%, the third The ore sample - 200 mesh accounted for 66.37%, the fourth ore sample - 200 mesh accounted for 74.18%, the fifth ore sample - 200 mesh accounted for 88.45%, and the sixth ore sample - 200 mesh accounted for 99.23%. Weigh 4000g of each particle size, and sort through the spiral chute for 3 times. The obtained iron ore concentrate products are dried and then sampled for testing. The grades are 48.41%, 52.15%, 58.64%, 63.49%, 66.37%, and 67.75%. .

[0048] Using the pycnometer method to measure the true specific gravity of the obtained different iron ore concentrate products, they were 3.94×10 3 kg / m 3 , 4.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com