Power transmission line grounding construction method

A construction method and transmission line technology, applied in the direction of circuits, line/collector components, connections, etc., can solve problems such as tower grounding resistance not meeting the requirements, lightning shielding, line tripping, etc., to prevent major construction quality accidents and Effects of Quality Management Incidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in more detail below by taking a grounding project of an overhead line pole and tower as an example.

[0016] (1) Project introduction

[0017] (1) The tower section is a stone trough with a soil cover of less than 0.3 meters in rocky areas.

[0018] (2) The base of the tower legs is configured with high and low legs in all directions, and grounding devices should be laid on each base tower.

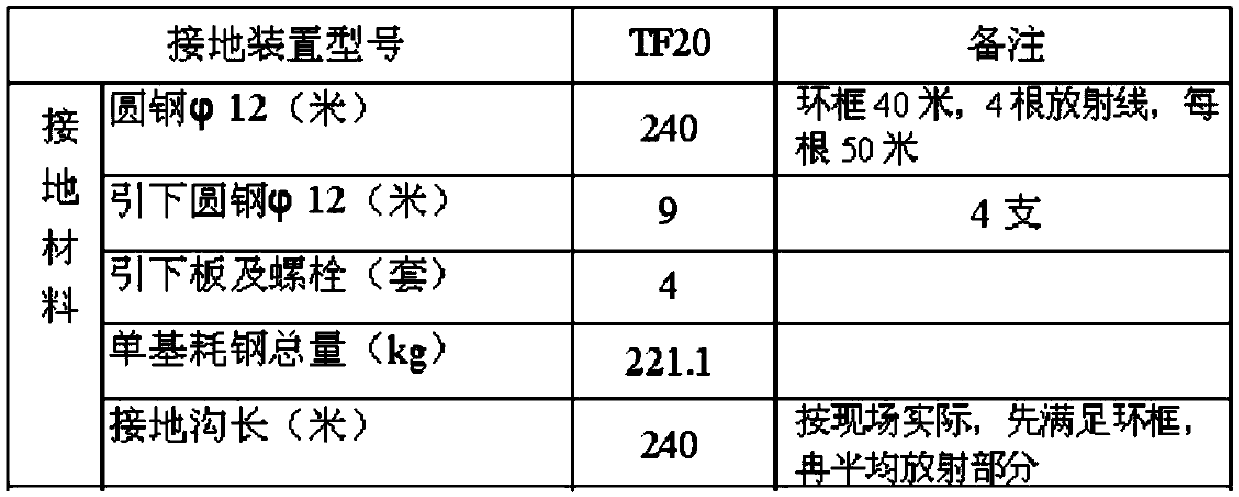

[0019] (3) Before the laying of the ground net, measure the resistivity of the soil, select the corresponding grounding device according to the measured soil resistivity, and check the drawings to check whether the required ground net material, buried depth, and length meet the requirements of the drawing. The statistics are as follows:

[0020]

[0021] (2) Construction instructions

[0022] (1) The grounding steel used in this bid section is all hot-dip galvanized.

[0023] (2) Earthwork for grounding devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com