LED light source control system based on microcomputer control

A LED light source and control system technology, applied in the field of industrial production, can solve problems such as high work intensity, failure to achieve assembly results, and fatigue of staff, and achieve the effect of improving quality and avoiding light deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

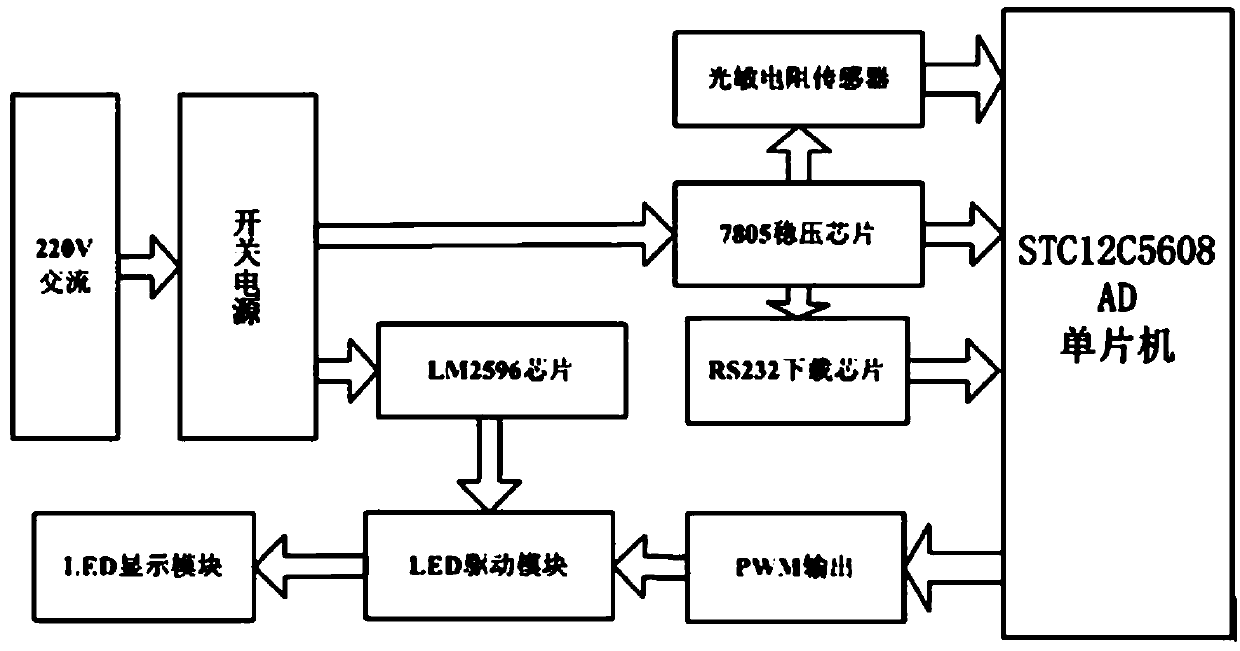

[0015] Such as figure 1 As shown, it is an overall framework diagram of the circuit design of the LED light source control system based on microcomputer control in the present invention. The figure includes single-chip MCU module, constant current voltage regulator module, 24V switching power supply module, and light source driving circuit module; the output of 220V AC power supply is connected to the switching power supply to generate 24V voltage output. 7805 voltage regulator chip module, the other is connected to the LM2596 chip; the output of the LM2596 chip is directly connected to the light source drive circuit module, the output of the 7805 voltage regulator chip module is connected in three ways, one is connected to the photoresistor sensor, and the other is connected to the The RS232 download chip is connected to the single-chip MCU module at the end; the outputs of the photoresistor sensor and the RS232 download chip are also connected to the single-chip MCU module. ...

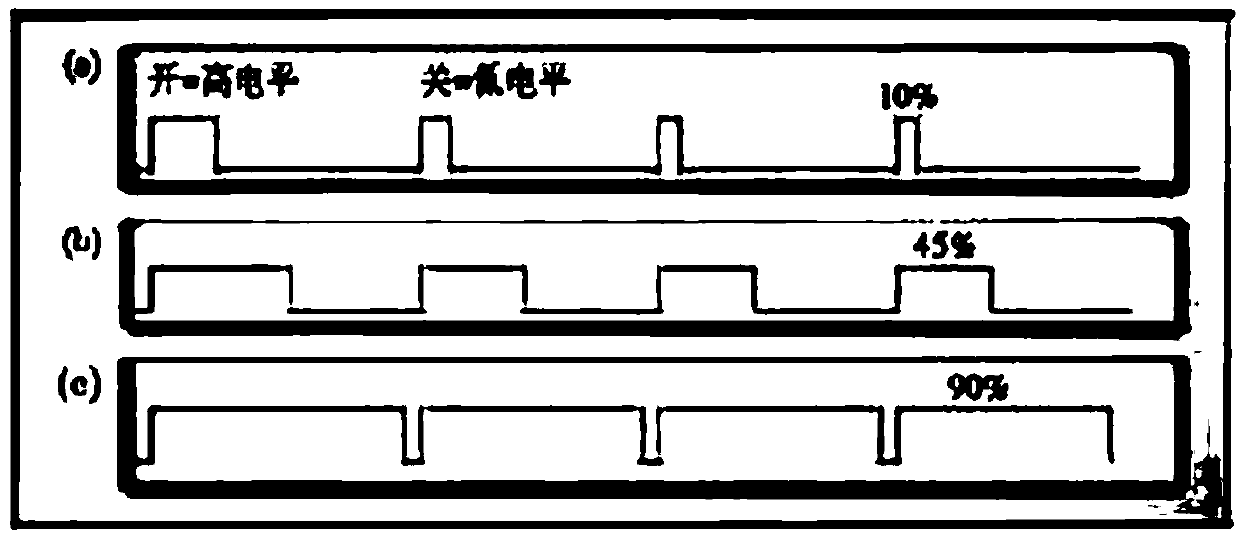

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com