Shoemaking lean workshop and control method thereof

A workshop and sewing machine technology, applied in the direction of shoe-making machinery, footwear, clothing, etc., can solve problems such as difficulty in orderly, synchronous connection, and low workshop output, so as to improve product qualification rate, increase quality supervision, and process technology. difficult effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

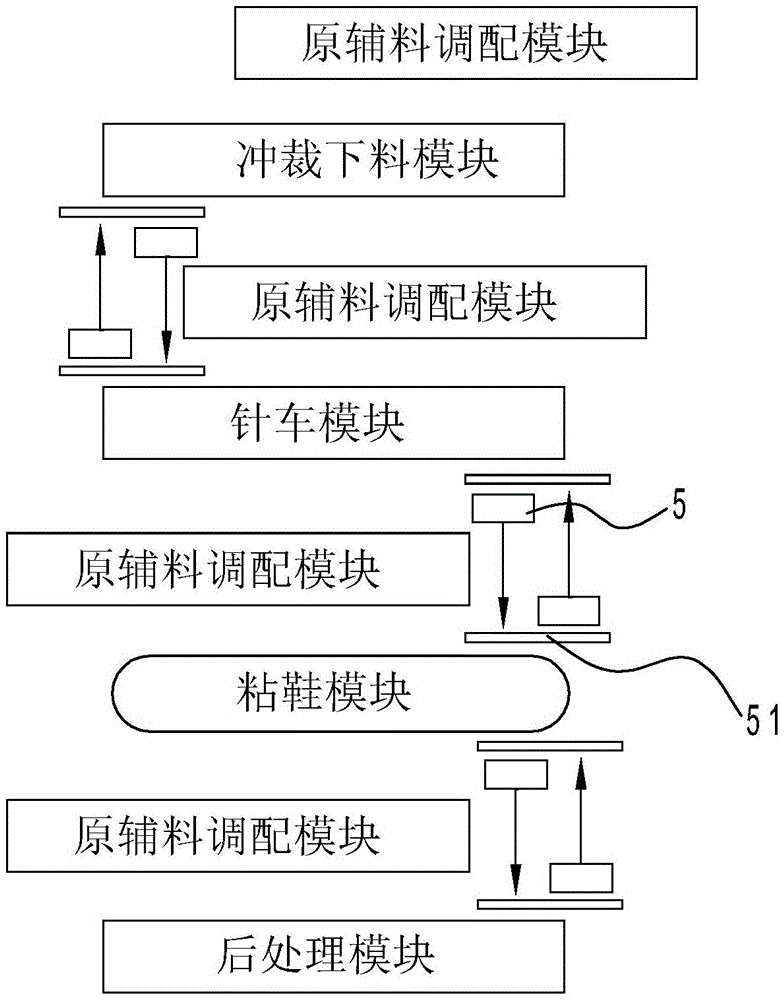

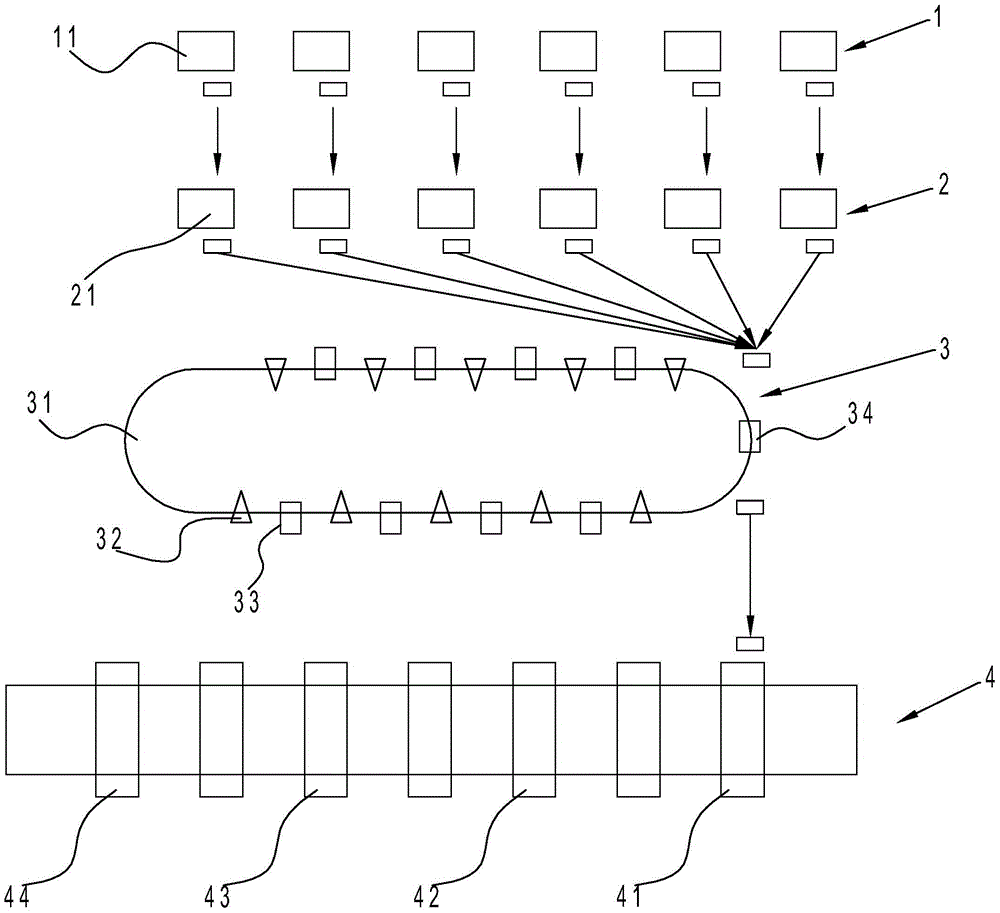

[0041]Example 1: Lean shoemaking workshop, taking the process of women's middle and high heels as an example, including a raw and auxiliary material blending module and a processing module. The raw and auxiliary material blending module is mainly used for scattered fabrics, shoelaces, sewing materials, shoe Allocation of raw materials such as glue and auxiliary materials; the processing module is divided into cutting and blanking module 1 for cutting original shoe materials and fabrics into pieces, sewing module 2 for sewing fabrics, and shoe sticking for bonding soles and uppers Module 3, the post-processing module 4 for heel on the sole, cleaning and inspection, the cutting and blanking module 1 includes six CNC cutting machines arranged side by side, and the sewing module 2 includes six roller cars arranged side by side 21. The shoe sticking module 3 includes a ring-shaped production line 3 that is first connected in a waist shape. A plurality of shoe-sticking workbenches 32...

Embodiment 2

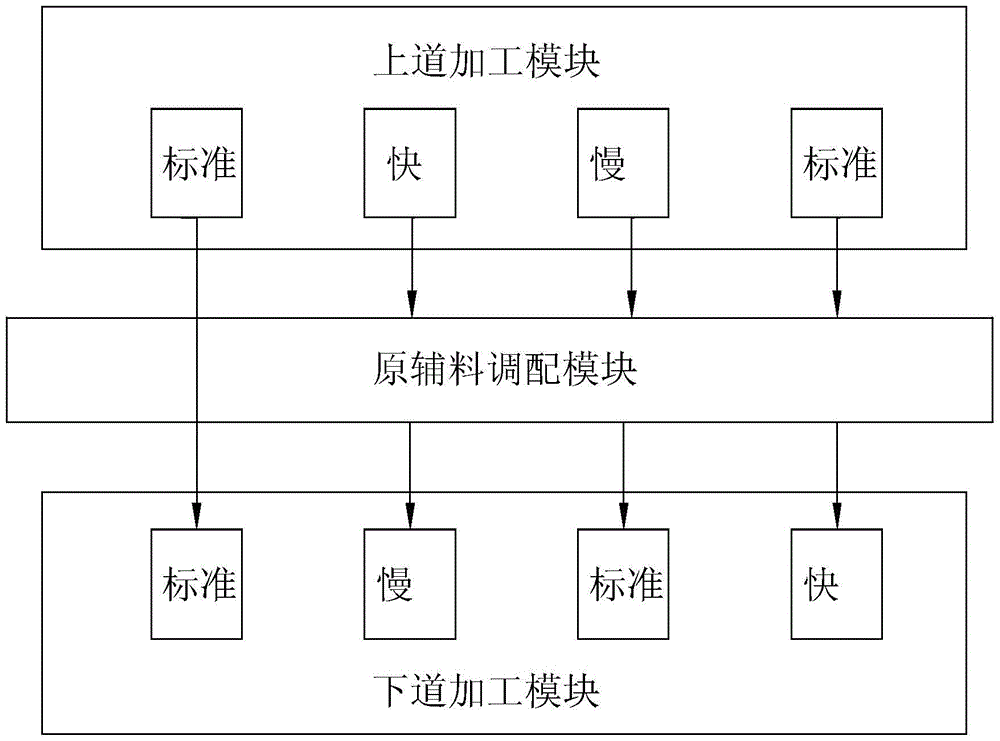

[0047] Embodiment 2, the difference between this embodiment 2 and embodiment 1 lies in the improvement of the utilization method of the raw and auxiliary material preparation unit. See attached image 3 , set the upper and lower processing modules to include at least 5 processing equipment / production lines, and under the preset output, the output of each upper and lower processing equipment / production line is roughly equal. Real-time information is detected by its weight detector. When the output of each upper and lower processing equipment / production line is balanced, the electric carrier 5 directly passes through the raw and auxiliary material blending module, and is transferred between the upper and lower processing modules. When there is a product gap between the upper and lower processing modules, the electric carrier vehicle first enters the raw and auxiliary material allocation module, and the upper processing module has a large output, unloads the part of the load that...

Embodiment 3

[0048] Example 3: Lean shoe-making workshop, including a raw and auxiliary material deployment module and a processing module. The processing module is divided into a cutting and blanking module 1, a sewing module 2, a shoe-sticking module 3, and a post-processing module 4. The material module 1, the sewing module 2, the shoe sticking module 3, and the post-processing module 4 are arranged side by side, and the raw and auxiliary material blending module is interspersed and arranged between each processing module; the cutting and blanking module includes several numerical control cutting machines arranged side by side , the sewing machine module 2 includes several roller cars 21 arranged side by side, the shoe sticking module 3 includes a circular production line 3, and a plurality of shoe sticking workbenches 32 are evenly arranged on the circular production line 3 lines, and in the circular production line One end of 3 is arranged with a lasting station 34 for fixing the shoe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com