Reboiler for supergravity rectification

A high-gravity rectification and reboiler technology, which is applied in fractionation, distillation separation, chemical instruments and methods, etc., can solve the problem of low heat exchange area and heat exchange efficiency of reboiler, difficulty in maintenance and replacement of heat exchange tubes, insufficient The use of heat energy and other issues, to achieve the effect of convenient regular inspection and maintenance, conducive to heat exchange efficiency, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

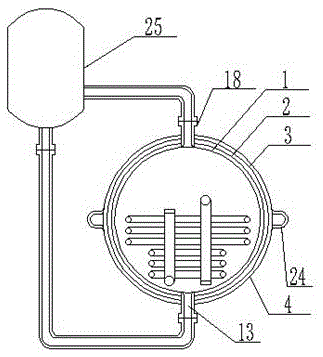

[0045] Such as Figure 1 to 9 As shown, the reboiler for high gravity rectification includes a reboiler and a rectification tower 25. The top of the reboiler is provided with a material gas phase outlet 18 and the bottom is provided with a natural reflux liquid inlet 13, and the material gas phase outlet 18 is connected to the rectification On the side of the tower 25, the natural reflux inlet 13 is connected to the bottom of the rectification tower 25;

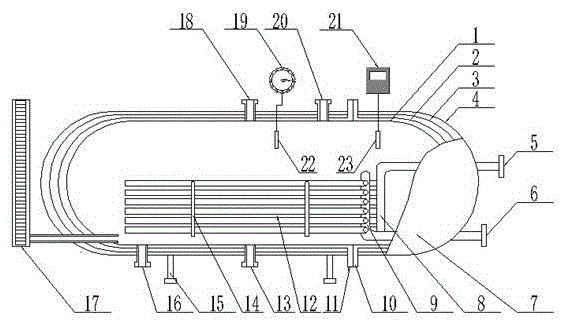

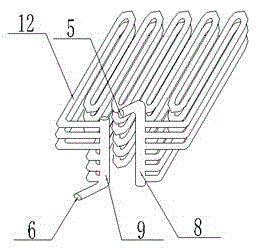

[0046] The reboiler includes a reboiler shell 1, an end cover 7, a heat exchange tube support frame 14, a shell support frame 15, a waste liquid discharge outlet 16, a material inlet 20, and heat exchange components. The reboiler shell 1 There is a material inlet 20 at the top and a waste liquid discharge outlet 16 at the bottom. A housing support frame 15 is provided at the bottom of the reboiler housing 1, and the reboiler housing 1 passes through a flange interface. 10 and flange interface 11 is connected to the end cover 7...

Embodiment 2

[0049] The reboiler for high-gravity rectification includes a reboiler and a rectification tower 25. The top of the reboiler is provided with a material gas phase outlet 18 and a natural reflux liquid inlet 13 at the bottom. The material gas phase outlet 18 is connected to the rectification tower 25. On the side, the natural reflux inlet 13 is connected to the bottom of the rectification tower 25;

[0050] The reboiler includes a reboiler shell 1, an end cover 7, a heat exchange tube support frame 14, a shell support frame 15, a waste liquid discharge outlet 16, a material inlet 20, and heat exchange components. The reboiler shell 1 There is a material inlet 20 at the top and a waste liquid discharge outlet 16 at the bottom. A housing support frame 15 is provided at the bottom of the reboiler housing 1, and the reboiler housing 1 passes through a flange interface. 10 and flange interface 11 is connected to the end cover 7. The wall surface of the end cover 7 is provided with a h...

Embodiment 3

[0053] The reboiler for high-gravity rectification includes a reboiler and a rectification tower 25. The top of the reboiler is provided with a material gas phase outlet 18 and a natural reflux liquid inlet 13 at the bottom. The material gas phase outlet 18 is connected to the rectification tower 25. On the side, the natural reflux inlet 13 is connected to the bottom of the rectification tower 25;

[0054] The reboiler includes a reboiler shell 1, an end cover 7, a heat exchange tube support frame 14, a shell support frame 15, a waste liquid discharge outlet 16, a material inlet 20, and heat exchange components. The reboiler shell 1 There is a material inlet 20 at the top and a waste liquid discharge outlet 16 at the bottom. A housing support 15 is provided at the bottom of the reboiler housing 1, and the reboiler housing 1 passes through a flange interface. 10 and flange interface 11 is connected to the end cover 7. The wall surface of the end cover 7 is provided with a heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com