Industrial emission volatile organic compounds (VOCs) tail gas on-site detecting evaluation device and method

An evaluation device and on-site detection technology, which is applied in the direction of measuring devices, separation methods, chemical instruments and methods, etc., can solve problems such as incomplete simulation, and achieve the effects of wide practical fields, high reliability, and accurate experimental data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

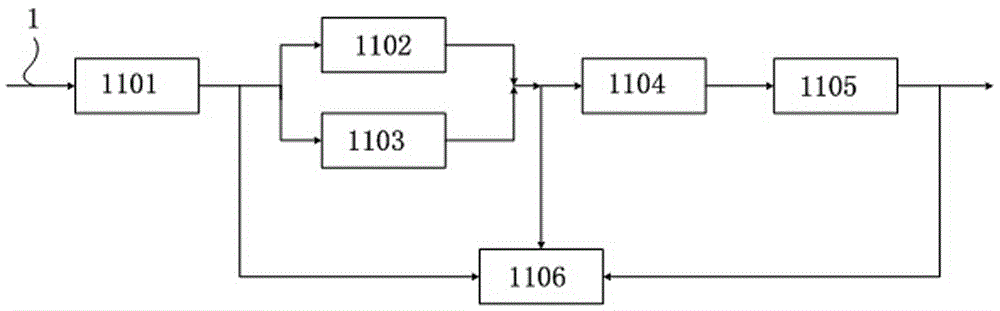

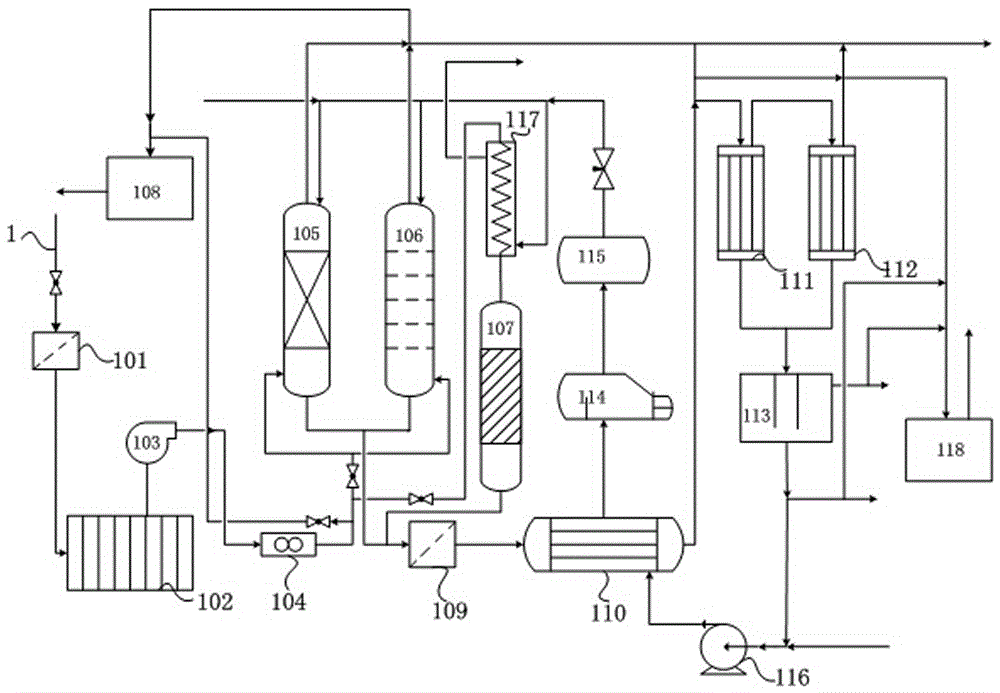

[0025] according to figure 1 The embodiment represented by -2 further describes the present invention:

[0026] An on-site evaluation device for industrial emission of VOCs tail gas, the evaluation device includes a pretreatment device 1101, a catalytic combustion device 1102, an adsorption / desorption device 1103, a heat coupling device 1104, a solvent separation device 1105, an online analysis device 1106 and a pipeline 1; The pretreatment device 1101 includes a filter 101, a surface cooler 102, a booster fan 103 and a gas mass flow meter 104; the catalytic combustion device 1102 includes a preheating tube 117 and a reaction tube 107; the adsorption / desorption Device 1103 includes adsorption tube A105, adsorption tube B106, steam heater 114, steam drum 115, circulation metering pump 116; described heat coupling device 1104 includes filter 109, thermal coupler 110; described solvent separation device 1105 includes A primary cooler 111 , a secondary cooler 112 , and an oil-wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com