Automatic surfacing welding machine for wear-resisting plates

An automatic surfacing and wear-resistant plate technology, which is applied to the characteristics of welding rods, welding equipment, welding equipment, etc., can solve the problems of uneven welding temperature, inconvenient installation and debugging, and influence on welding quality, and achieve short weld bead length and good appearance. Improve the leveling quality and ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

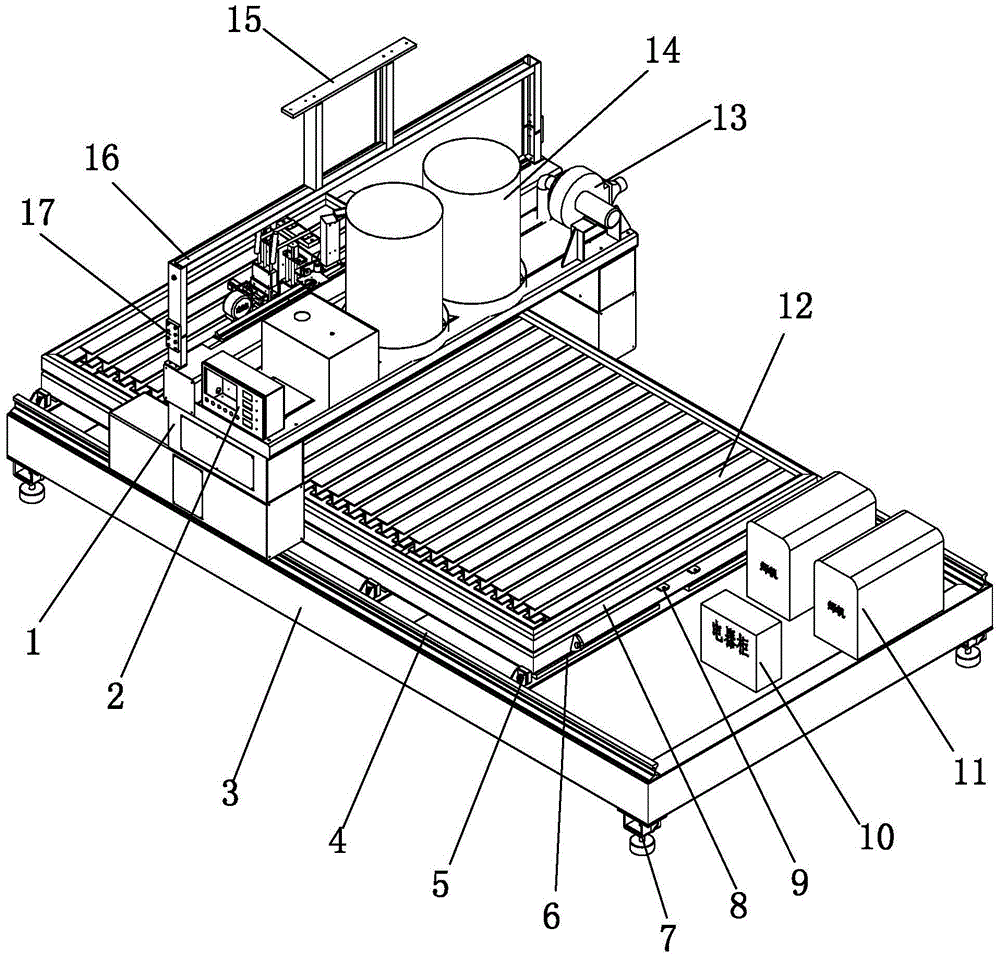

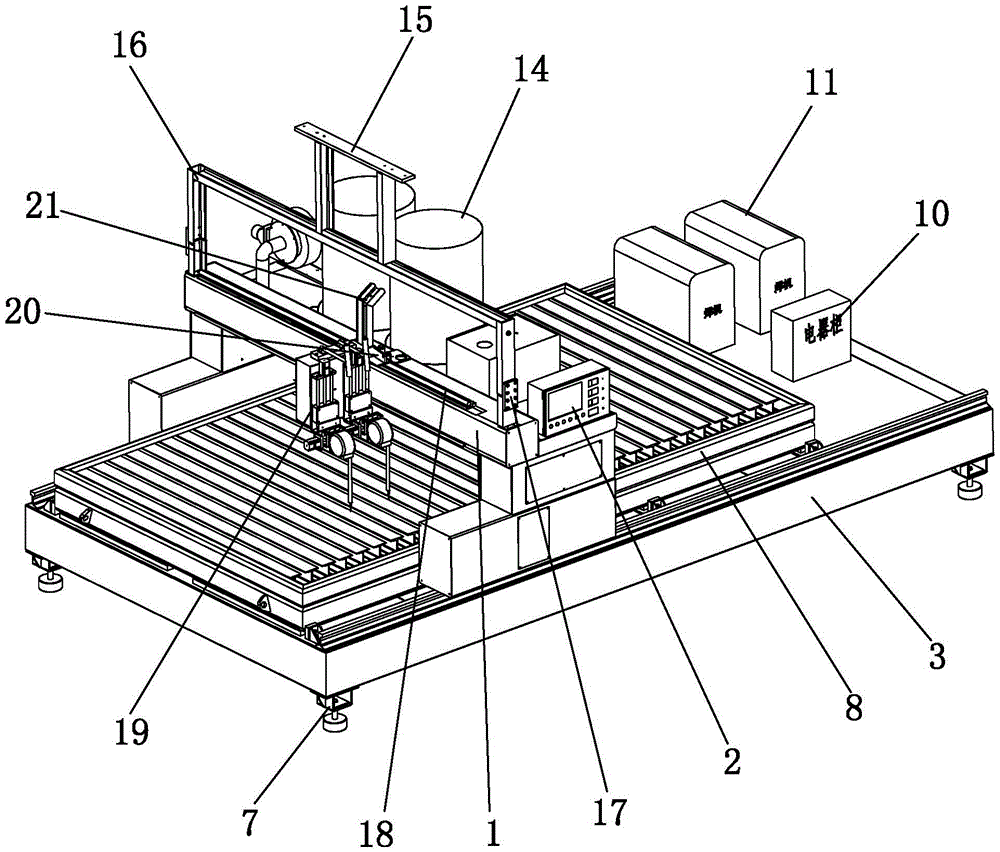

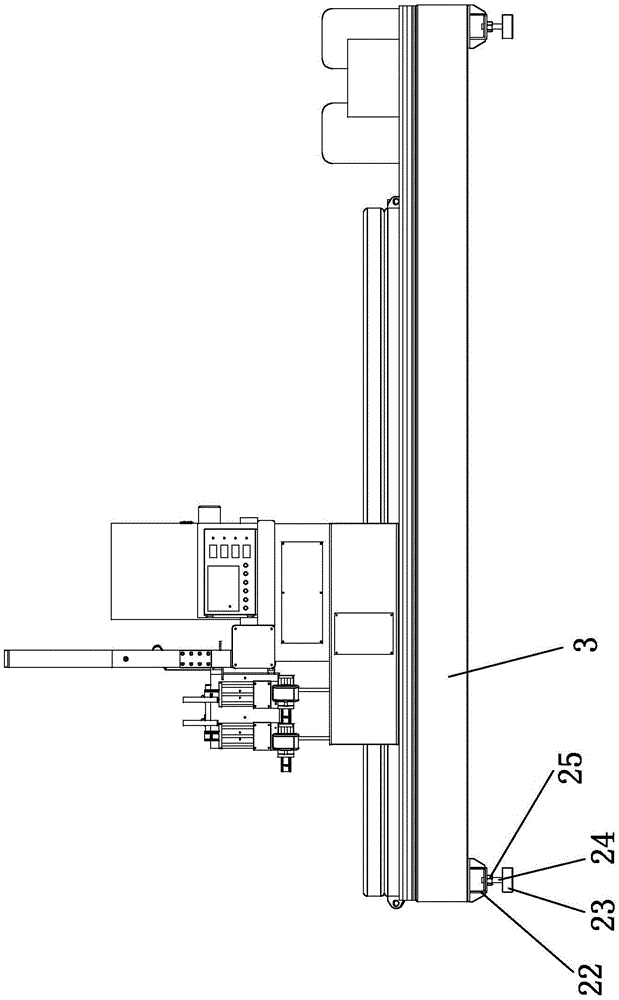

[0015] Such as Figure 1 to Figure 3 As shown, the wear-resistant plate automatic surfacing welding machine of the present invention includes a chassis 3, a workbench, an automatic welding device 19, a welding machine 11, an electrical cabinet 10, an exhaust fan 13, a console 2, and four corners at the bottom of the chassis 3 Respectively be connected with adjustment support seat 7, and adjustment support seat 7 comprises square-shaped support member 22, connecting screw rod 24, adjustment nut 25, base 23, and square-shaped support member 22 is connected on the bottom surface of underframe 3, and connection screw rod 24 bottoms and base 23 is fixedly connected, the upper end of the connecting screw 24 passes through the end wall of the bottom end of the mouth-shaped support 22, and the adjustment nut 25 is connected on the connecting screw 24 and is located below the bottom end wall of the mouth-shaped support 22, which can be adjusted by adjusting the adjustment nut 25 Connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com