A kind of metal-resin composite and preparation method thereof

A composite and metal matrix technology, applied in the field of metal-resin composites and their preparation, can solve problems such as insufficient anti-rotational moment ability, and achieve improved resistance to tensile stress, good resistance to rotational moment, and high resistance to rotation. The effect of torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] (1) Making metal substrate

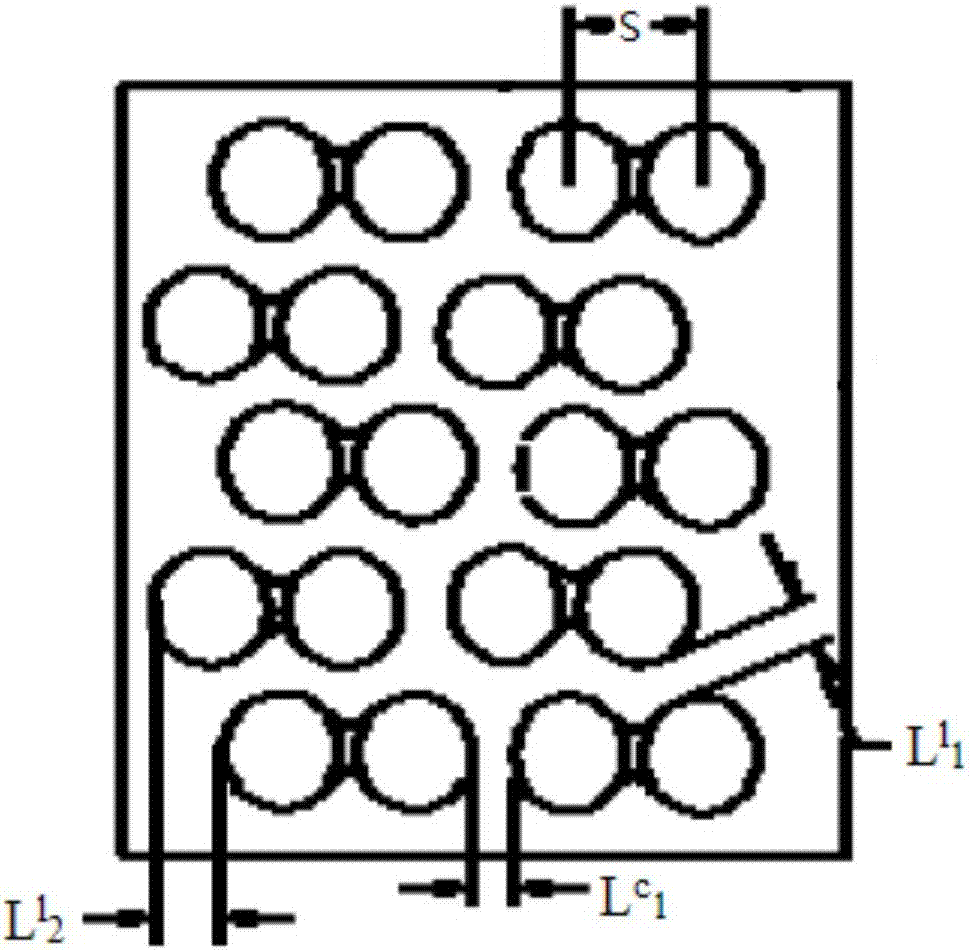

[0081](1-1) Use the CorelDRAW drawing software to design the arrangement map file of the hole, and input it into the control unit of the laser, so that the laser can be placed on the aluminum alloy substrate (purchased from Titanium Technology Co., Ltd.) as the metal substrate according to the arrangement map file. Co., Ltd., the brand name is A6061) on the surface forms holes that exist in pairs and intersect at the bottom, and at the same time make the holes in pairs as a unit and arrange them into a two-dimensional lattice.

[0082] Among them, according to Figure 4 to Figure 13 The method is to form a pair of holes with intersecting bottoms on the surface of the aluminum alloy substrate, and the specific process flow is as follows.

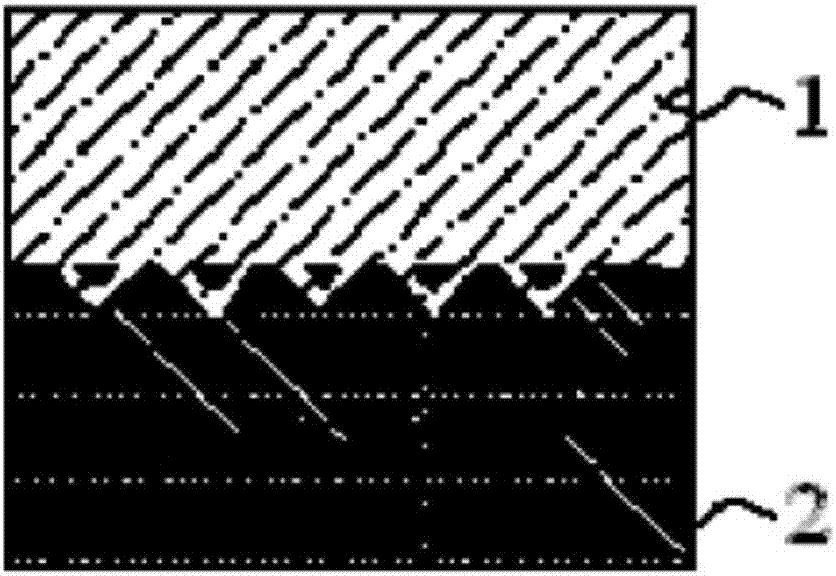

[0083] The first step: if Figure 4 and 5 As shown, the laser beam 4 is obliquely incident with respect to the surface of the metal substrate 3 (in a clockwise direction, the incident angle of the laser ...

Embodiment 2

[0096] (1) Making metal substrate

[0097] The metal matrix was fabricated by the same method as in Example 1, except that, in the two-dimensional lattice, there was no misalignment between two adjacent rows (that is, there was no staggered arrangement between two adjacent rows).

[0098] (2) Making metal-resin composites

[0099] The metal-resin composite was fabricated by the same method as in step (2) of Example 1, except that the metal matrix was the metal matrix produced in step (1) of Example 2.

[0100] The mechanical property data of the prepared metal-resin composites are listed in Table 1.

Embodiment 3

[0102] (1) Making metal substrate

[0103] The metal substrate was fabricated by the same method as in step (1) of Example 1, except that step (1-2) was not performed.

[0104] (2) Making metal-resin composites

[0105] The metal base was fabricated by the same method as in step (1) of Example 1, except that the metal base was the metal base prepared in step (1) of Example 3.

[0106] The mechanical property data of the prepared metal-resin composites are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com