CO2 gas protected single-sided welding and double-sided forming process

A single-sided welding double-sided, gas shielding technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of too thin weld bead, low welding efficiency, fast welding speed, etc., to improve the resistance to tensile stress Ability, avoid thermal cracks, increase the thickness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

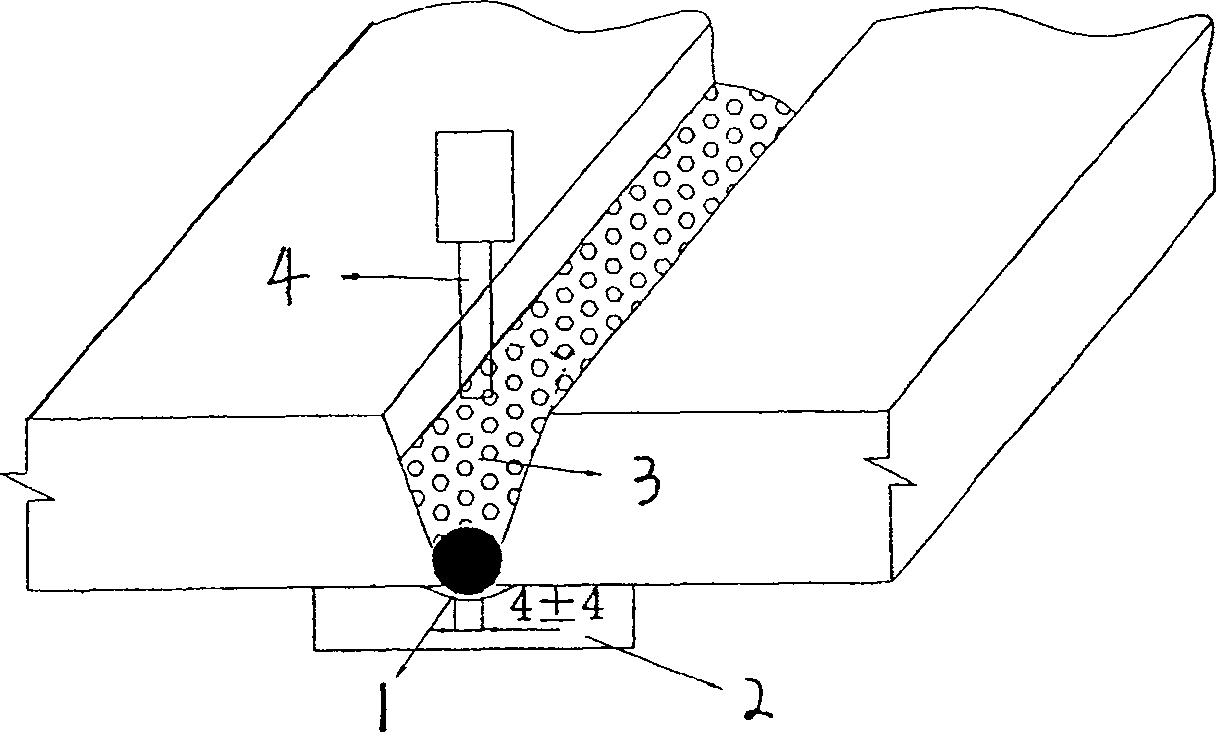

[0024] CO in this example 2 Gas-shielded single-sided welding double-sided forming welding process, which includes the following steps: (1) opening a groove 1 on the butt weldment, and the gap between the groove 1 is 0.05 mm; (2) spot welding and fixing in the groove 1; 3) Paste ceramic liner 2 on the reverse side of groove 1; (4) Fill scrap metal wire 3 in groove 1, and the thickness of scrap metal wire 3 should ensure that the welding seam of the first layer is 10mm; (5) Carry out the first layer root pass, i.e. in CO 2 Under gas protection, a current of 540 amperes is used for single-sided automatic welding, and a larger welding current is used to melt the spot-welded weld and the base metal at the root of the narrow groove that cannot be melted by conventional processes, and become a part of the root weld. Specification features: metal cored flux cored wire 4 is used, the specification of metal cored flux cored wire 4 is φ1.6mm, the welding position is V-groove flat butt ...

Embodiment 2

[0026] CO in this example 2 Gas-shielded single-sided welding double-sided forming welding process, which includes the following steps: (1) opening a groove 1 on the butt weldment, and the gap between the grooves 1 is 3.5 mm; (2) spot welding and fixing in the groove 1; 3) Paste ceramic liner 2 on the reverse side of groove 1; (4) fill scrap metal wire 3 in groove 1, and the thickness of scrap metal wire 3 should ensure that the welding seam of the first layer is 8 mm; (5) carry out the first layer root pass, i.e. in CO 2 Under gas protection, a current of 480 amperes is used for single-sided automatic welding, and a larger welding current is used to melt the spot-welded weld and the base metal at the root of the narrow groove that cannot be melted by conventional processes, and become a part of the root weld. Specification features: The metal core type flux cored wire 4 is used, the specification of the metal core type flux cored wire 4 is φ1.6mm, the welding position is V-s...

Embodiment 3

[0028] CO in this example 2 Gas shielded single-sided welding and double-sided forming welding process, which includes the following steps: (1) opening a groove 1 on the butt weldment, and the gap between the groove 1 is 8 mm; (2) spot welding and fixing in the groove 1; 3) Paste the ceramic liner 2 on the reverse side of the groove 1; (4) fill the groove 1 with broken metal wire 3, and the thickness of the broken metal wire 3 should ensure that the welding seam of the first layer is 7 mm; (5) carry out the first layer root pass, i.e. in CO 2 Under gas protection, a current of 420 amperes is used for single-sided automatic welding, and a larger welding current is used to melt the spot-welded weld and the base metal at the root of the narrow groove that cannot be melted by conventional processes, and become a part of the root weld. Specification features: metal cored flux cored wire 4 is used, the specification of metal cored flux cored wire 4 is φ1.6mm, the welding position i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com