Power battery pack active air cooling heat radiating system for vehicle and control method thereof

A power battery pack and heat dissipation system technology, which is applied in the direction of battery/fuel cell control devices, secondary batteries, electric vehicle charging technology, etc. Poor effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The purpose of the present invention is to improve the heat dissipation efficiency of the electric vehicle power battery pack, and provide an active air-cooled heat dissipation system for the power battery pack based on fuzzy control, so as to realize real-time changes of the heat dissipation system with different states of the power battery.

[0069] The technical solution of the present invention will be described below in conjunction with the accompanying drawings, which describe only a part of the invention rather than all embodiments.

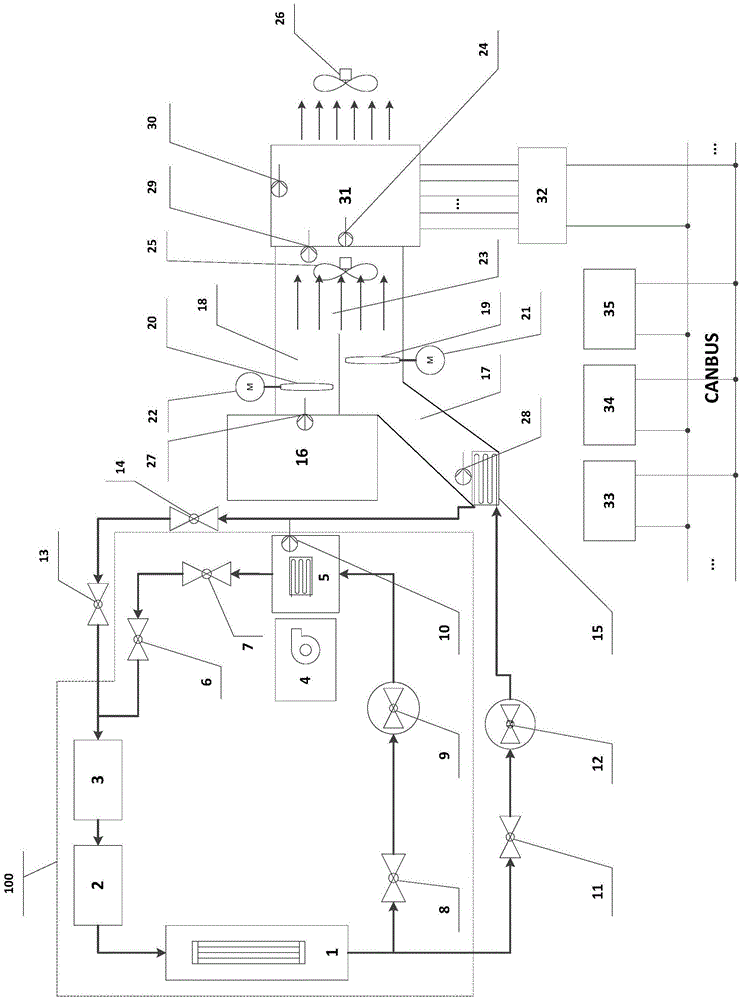

[0070] as attached figure 1 As shown, it is an active air-cooled heat dissipation system for a vehicle power battery pack provided by the present invention, which includes a passenger compartment air-conditioning system 100 (including a condenser 1, an electric compressor 2, a liquid storage tank 3, a blower 4, and a No. 1 evaporator Device 5, No. 1 one-way valve 6, No. 1 evaporating pressure regulating valve 7, No. 1 solenoid valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com