Integrated control valve assembly-actuating cylinder separated hydraulic servo actuator

A hydraulic servo and actuator technology, which is applied in aircraft transmission, aircraft power transmission, aircraft power devices, etc., can solve problems such as the influence of control system and structure life, large installation space, etc., to improve design efficiency and reduce cost. Effects of small torsional moments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

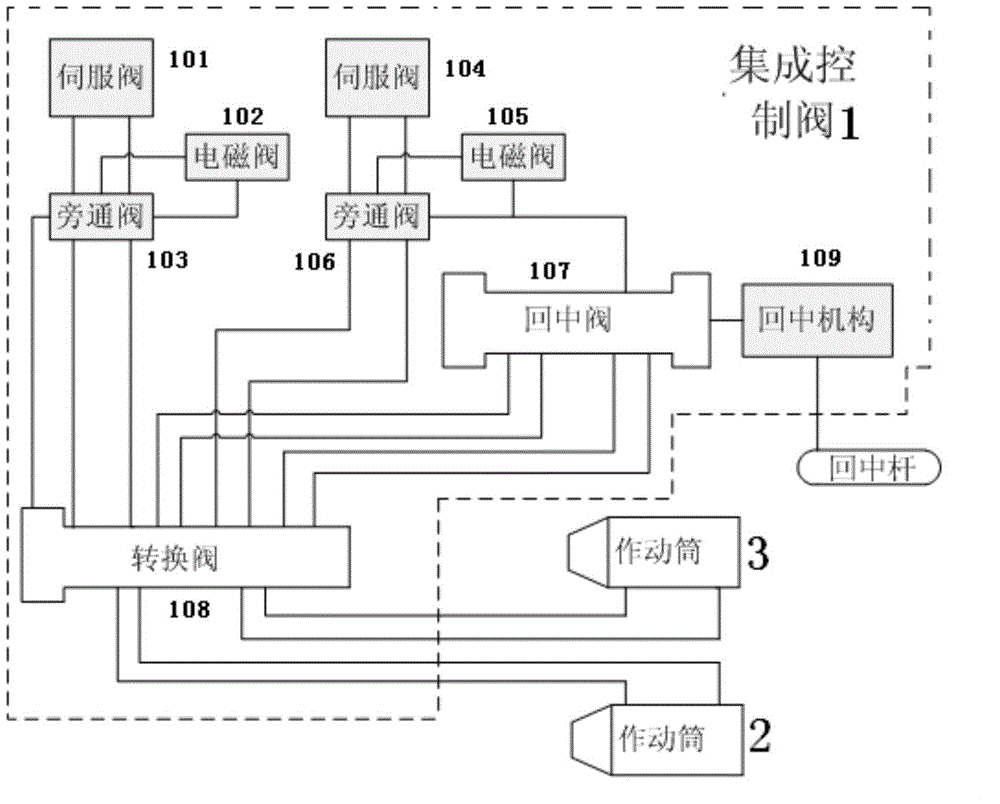

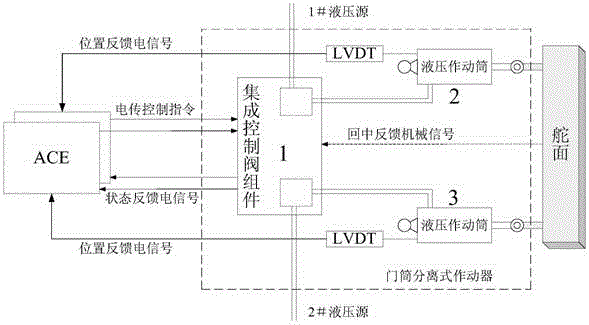

[0016] In order to overcome the arrangement of high-power hydraulic servo actuators in a small space and improve the maintainability of the product, a hydraulic servo actuator with door cylinder separation is designed, including integrated control valve assembly 1, first actuator cylinder 2 and The second cylinder 3. Among them, the integrated control valve assembly 1 includes a first servo valve 101, a first solenoid valve 102, a first bypass valve 103, a second servo valve 104, a second solenoid valve 105, a second bypass valve 106, and a centering valve 107. , switching valve 108 and centering mechanism 109, wherein the first servo valve 101, the first solenoid valve 102, the first bypass valve 103, the switching valve 108 and the first actuator 2 form the No. 1 channel; the first servo valve 101 is the main control valve, and the first solenoid valve 102 controls the on-off of the hydraulic oil. After the first solenoid valve 102 is powered on, the hydraulic oil enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com