Swaying traction system and method for platforms

A traction system and platform technology, applied in the field of working condition simulation test, can solve problems such as friction loss, leakage loss, system stability, and unsuitable for long-distance transmission, and achieve the effect of low cost, simple structure, and far-reaching practical engineering application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

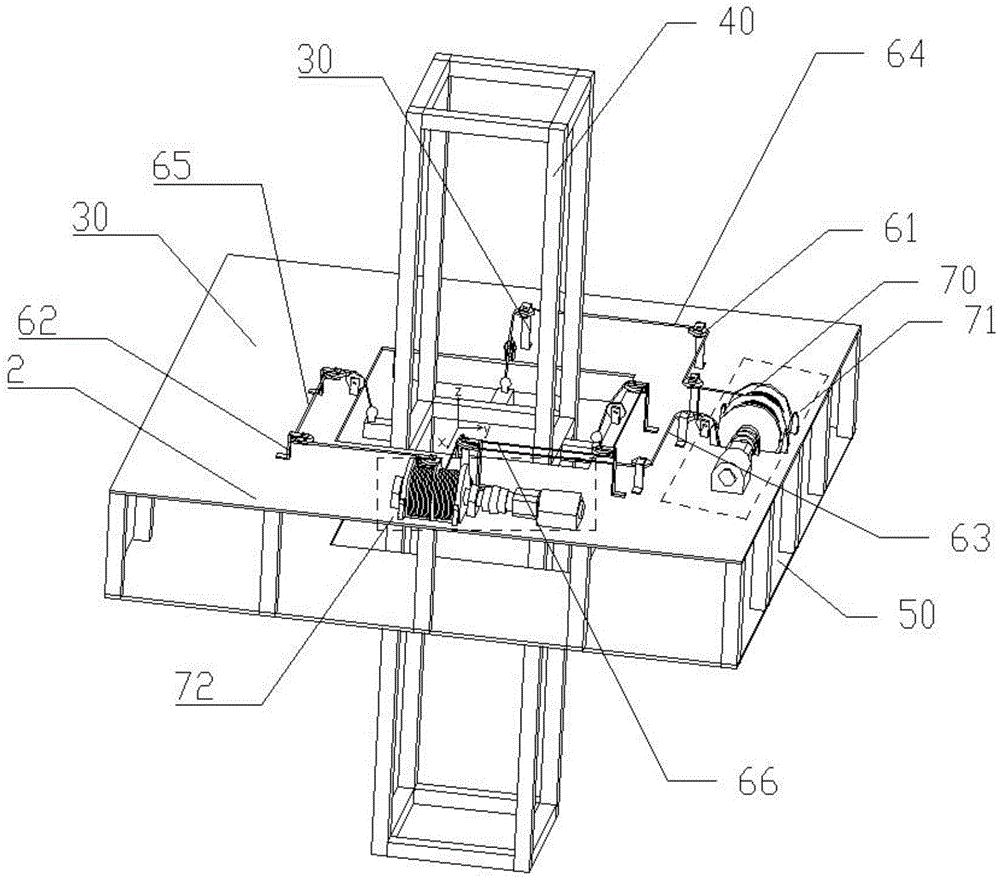

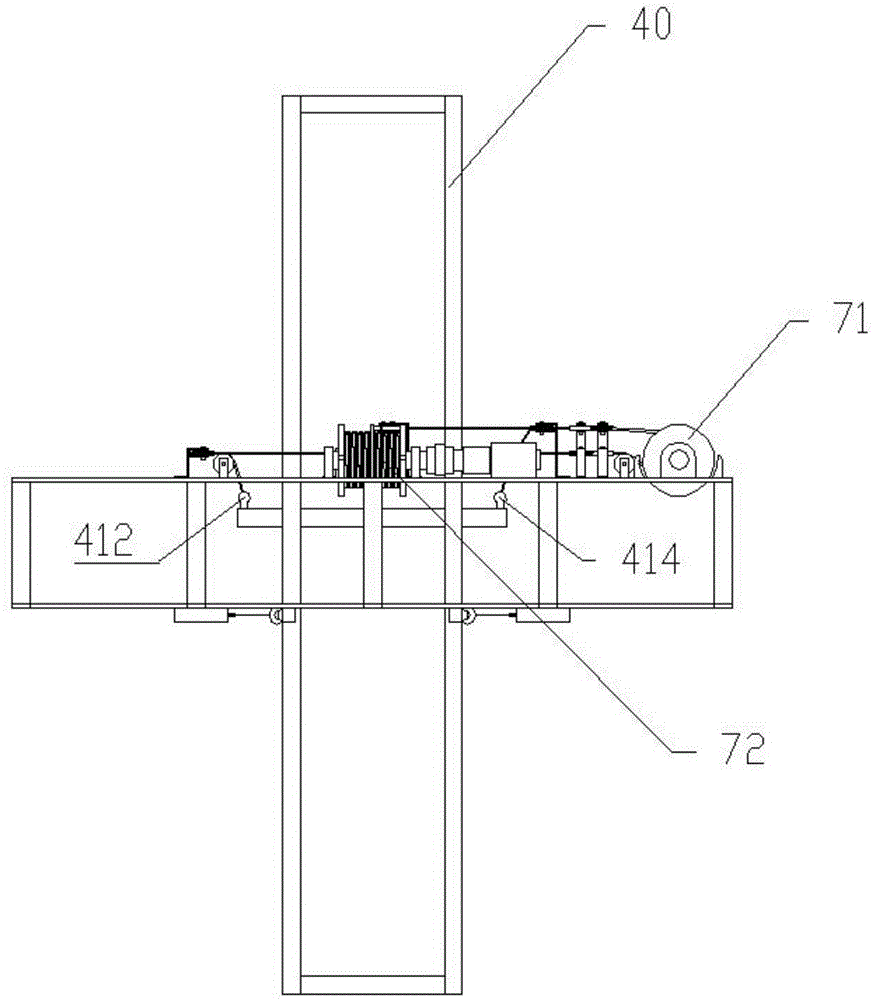

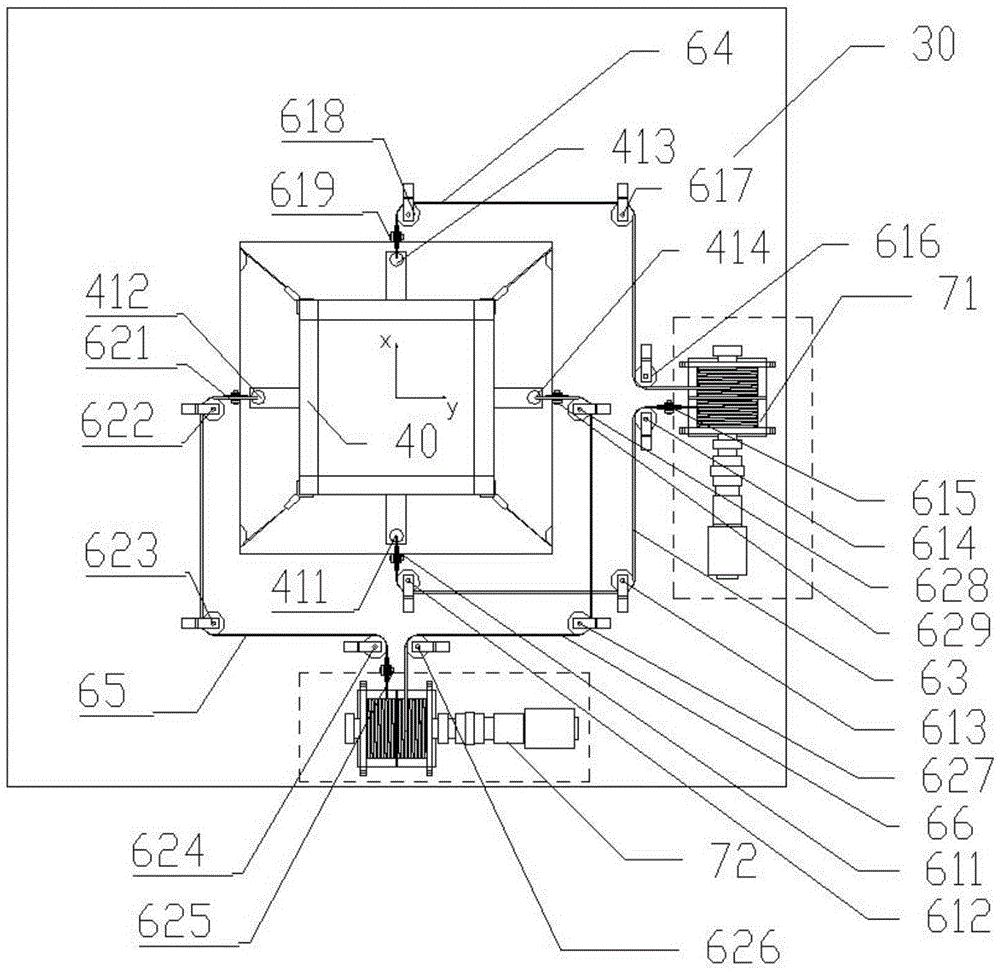

[0036] Such as Figure 1 to Figure 8 Shown: the present invention includes vertically arranged truss platform 2 and the derrick 40 passing through the through hole of truss platform 2 longitudinally; Drive system 70, four stabilizing systems 90 arranged on the lower platform 50 of the truss platform 2; the coordinate axis XYZ is established with the center of the derrick 40, and the XYZ center plane of the derrick 40 coincides with the XYZ center plane of the truss platform 2 during initial setting;

[0037] The reel drive system 70 includes the first reel drive system 71 and the second reel drive system 72; the guide traction system includes the pulley guide system 61 on the XZ, the pulley guide system 62 on the YZ, the first drive wire rope 63, the second drive Wire rope 64, the third driving wire rope 65 and the fourth driving wire rope 66; the derrick 40 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com